Product parameter

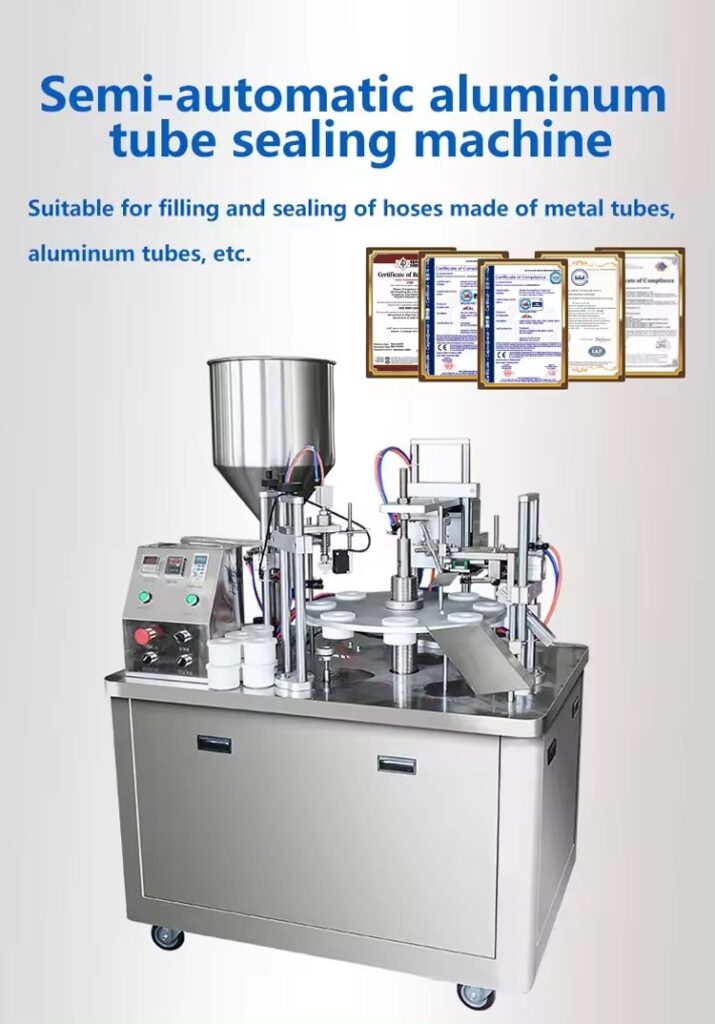

Plastic tube filling and sealing machine adopts indexing device, completing a series of functions, including automatic filling, inside and outside heating, end-sealing, batch number printing, and finished product exiting. The machine is featured by accurate filling, stable and adjustable heating time, good sealing effect. The machine has ten tubes which can work automatically. The machine works stably and reliably, without noise and other pollution.

All the parts of the machine that contact materials are made of high-quality stainless steel. For parts that need to be cleaned, they are easy to disassemble and wash. When some materials need to be heated and kept warm, a heating and temperature-maintaining device can be installed on the outside of the barrel.

| voltage | 220v 50hz |

| power | 0.9kw |

| Filling range | 5-400ml |

| Tube diameter | 10-50mm |

| Tube length | 50-300mm |

| Speed | 20-30pcs/min |

| Filling precision | ±1% |

| Machine dimension | 1250*950*1005mm |

| Machine weight | 350kg |

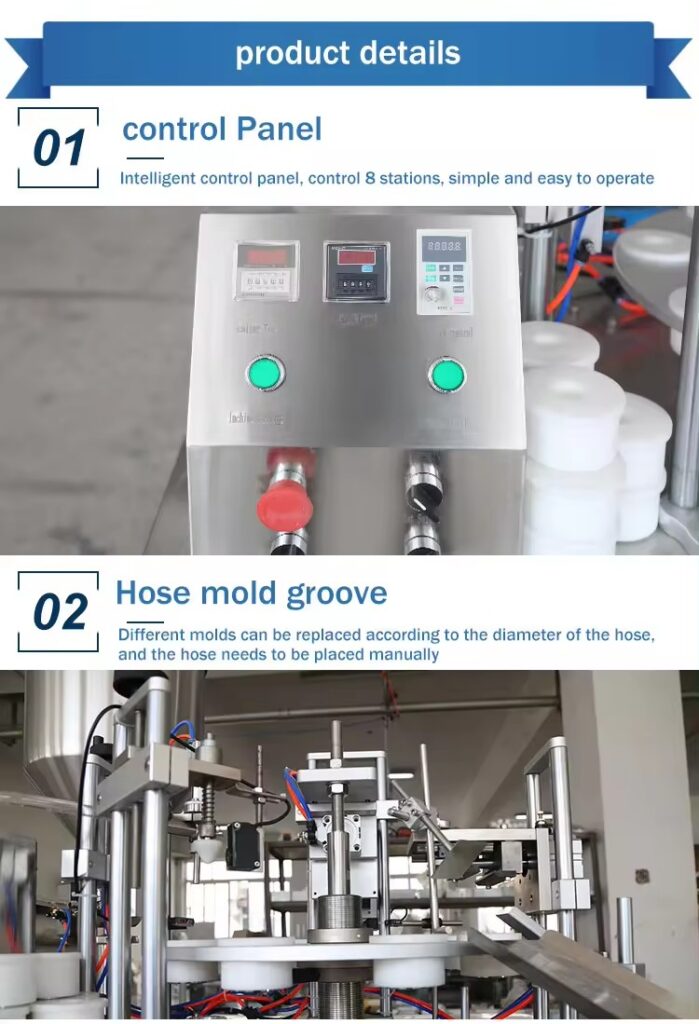

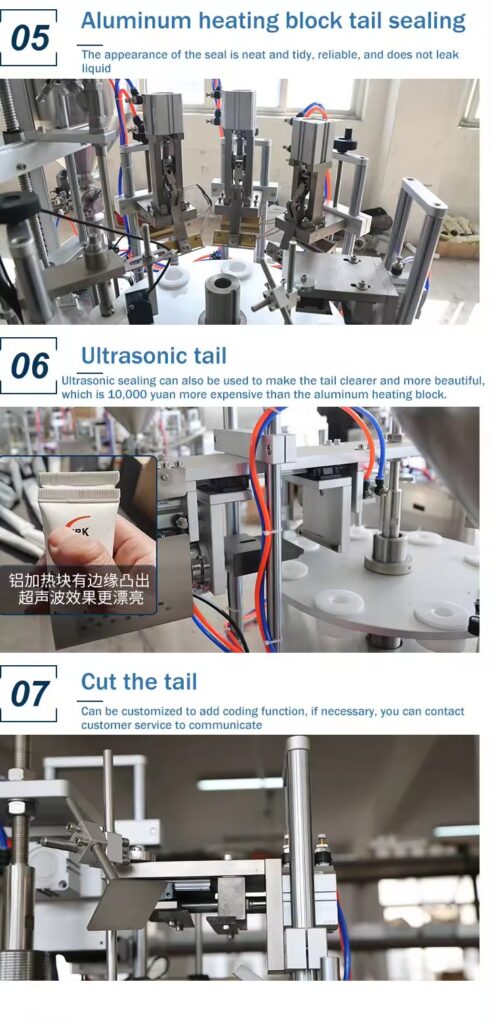

Product details

Applicable product

FAQ

Plastic tube filling and sealing machine adopts indexing device, completing a series of functions, including automatic filling, inside and outside heating, end-sealing, batch number printing, and finished product exiting. The machine is featured by accurate filling, stable and adjustable heating time, good sealing effect. The machine has ten tubes which can work automatically. The machine works stably and reliably, without noise and other pollution.

All the parts of the machine that contact materials are made of high-quality stainless steel. For parts that need to be cleaned, they are easy to disassemble and wash. When some materials need to be heated and kept warm, a heating and temperature-maintaining device can be installed on the outside of the barrel.