The Bag sealer refers to the machine that seals the container after the product is filled in the packaging container. There are many materials for making packaging containers, such as paper, plastic, glass, ceramics, metals, composite materials, etc., and the shapes and physical properties of packaging containers are also different. Therefore, the sealing forms and sealing devices used are also different. After the product is packed into the packaging container, in order to keep the product sealed, maintain product quality, and avoid product loss, the packaging container needs to be sealed. This operation is done on a bag sealers for food.

The plastic bag sealer is now widely used, and the operation is simple and the process is fast, but many people do not understand the working principle of the Bag sealer machine. Let me introduce it to you today. Only by understanding the working principle can it be helpful for future maintenance and machine model selection,and also the plastic bag sealer .

When the package containing the articles is placed on the conveyor belt, the sealing part of the bag of the sealing machine is automatically sent between the two sealing belts in operation, and brought into the heating zone, and the heat of the heating block is transferred to the bag through the sealing bag In the sealing part, the film is melted and softened by heat. After passing through the cooling zone, the surface temperature of the film is appropriately lowered, and then rolled by the knurling wheel (or printing wheel), so that the upper and lower plastic films of the sealing part are bonded and pressed to form a reticular pattern ( or printed logo) and then the sealed packaging bag is sent out of the machine by the guide rubber belt and the conveyor belt to complete the sealing operation.

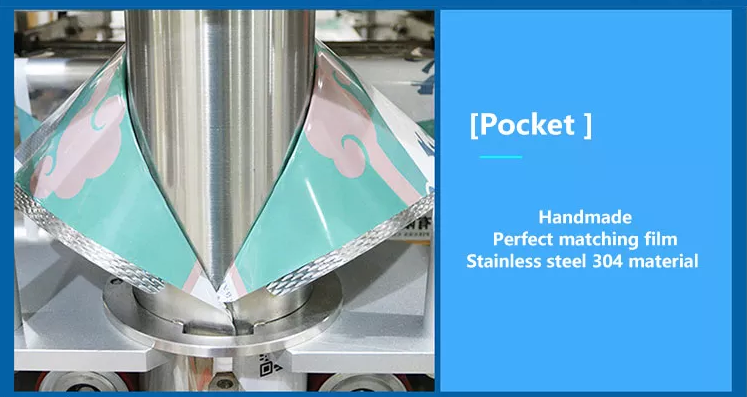

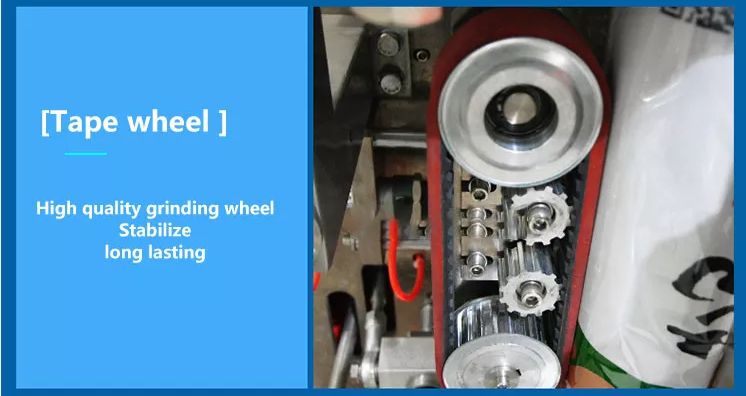

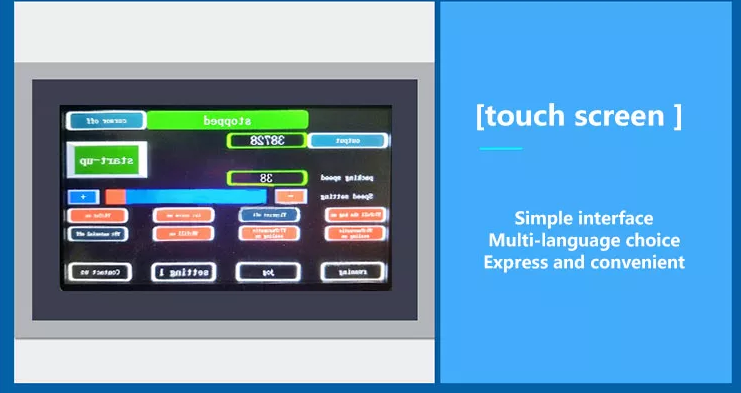

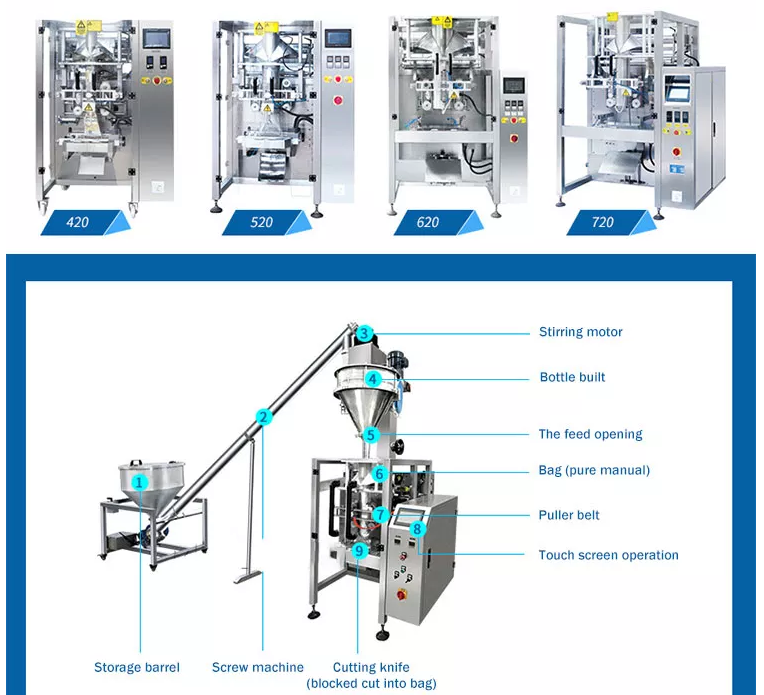

Pictures of the machine and detail parts

Advantages of the Bag sealer

1. Conducive to the labor protection of workers For some products that seriously affect the health of the body, such as heavy dust, toxic products, irritating and radioactive products, manual packaging will inevitably endanger health, while mechanical packaging can be avoided, and can Effectively protect the environment from pollution.

2. It can effectively guarantee the quality of packaging. Mechanical packaging can obtain packaging with consistent specifications according to the requirements of the packaging items, according to the required shape and size, while manual packaging cannot be guaranteed. This is especially important for export commodities. Only mechanical packaging, In order to achieve the standardization and standardization of packaging, it meets the requirements of collective packaging.

3. It can realize the operations that cannot be realized by manual packaging. Some packaging operations, such as vacuum packaging, inflatable packaging, skin packaging, isobaric filling, etc., cannot be realized by manual packaging, and can only be realized by mechanical packaging.

4. It can reliably ensure the hygiene of products. Some products, such as food and drug packaging, are not allowed to be packaged by hand according to the Sanitation Law, because they will pollute the product, while mechanical packaging avoids direct contact with food and drugs by human hands and ensures hygiene. quality

Bag sealer features:

Application Picture

This machine is suitable for the sealing operations of various heat-sealed bags such as aluminum foil bags,plastic bags,composite bags,cowhide bags,fresh-keeping bags,tea bags,shrink films,etc.,with firm sealing and high efficiency.It is widely used in food,medicine,chemical industry,and agriculture.,Lubricants and other industries.

Description about Sealing Machine

| Production capacity | 15-60bags/min |

| Measuring range | 200-2000ml |

| Bag size | L:80-360mm W:100-250mm |

| Total power | 2.5kw |

| Power supply voltage | 220v 2.4kw |

| Packaging material | OPP/CPP/CPPE |

| Machine weight | 550kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Plastic Sealing Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

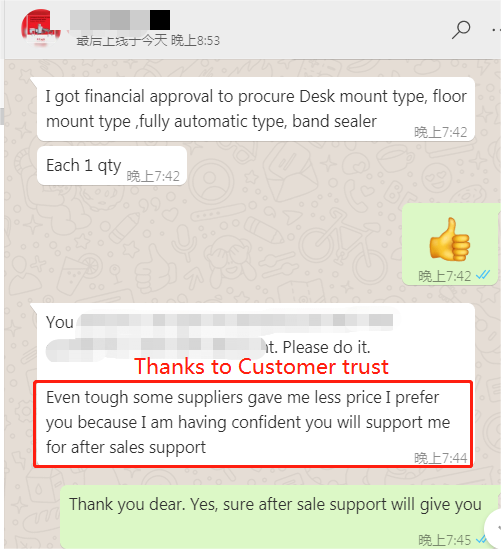

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.