- PRODUCT DETAIL

The chocolate packing machine adopts the common electric furnace wire heating method, which is characterized by fast heating and low maintenance cost. So do you know what is the difference between the upper paper and the lower paper of the pillow packaging machine? Below I will give you a brief introduction.

The chocolate bar packing machine are generally divided into the following categories:

1. Rotary pillow packaging machine: It cuts the packaging film through the rotary motion of the transverse sealing knife to complete the packaging.

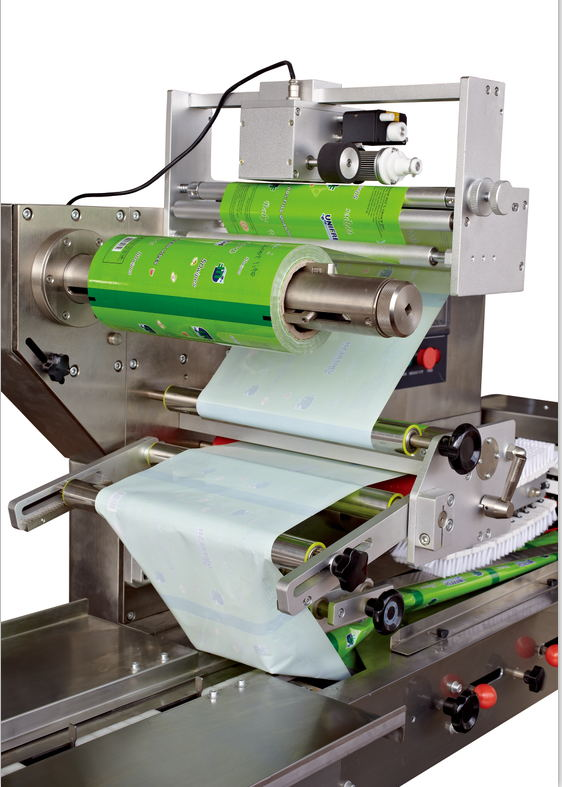

1. Up-going paper of chocolate packing machine pillow packaging machine: it means that the packaging film roll is above the reference level of the packaging machine (that is to say, the packaging film is above the transverse sealing cutter)

The up-going film pillow packaging machine is a packaging machine in which the wrapping paper is moved above the product, so as to be packaged from top to bottom.

The top film of the pillow packaging machine is wrapped from top to bottom when the film is wrapped, and there may be some cases where the feeding material cannot be delivered in place and cannot be sent to the top of the film. If the film goes down, the film comes out from below. When feeding, the push rod is pushed directly to the top of the film, and the product follows the film directly.

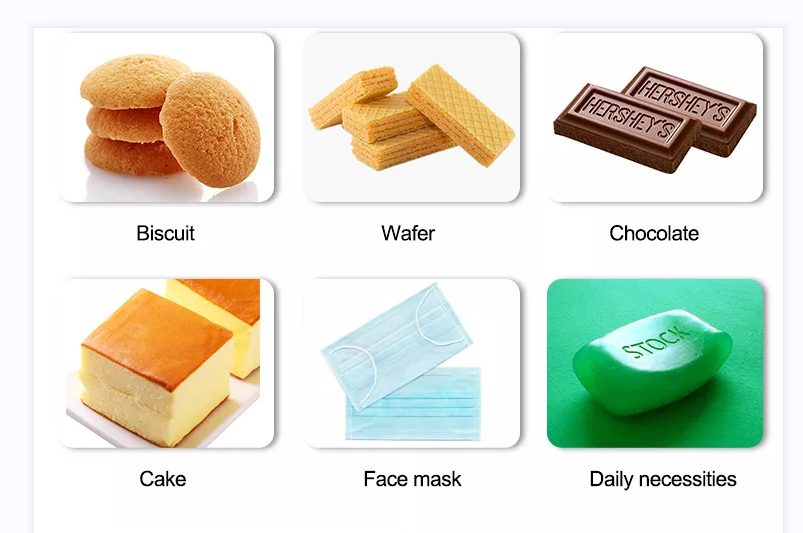

Paper on the top of chocolate packing machine is suitable for the packaging of various regular objects such as biscuits, rice tongs, snow cakes, egg yolk pie, chocolate, bread, instant noodles, moon cakes, daily necessities, industrial parts, cartons or trays.

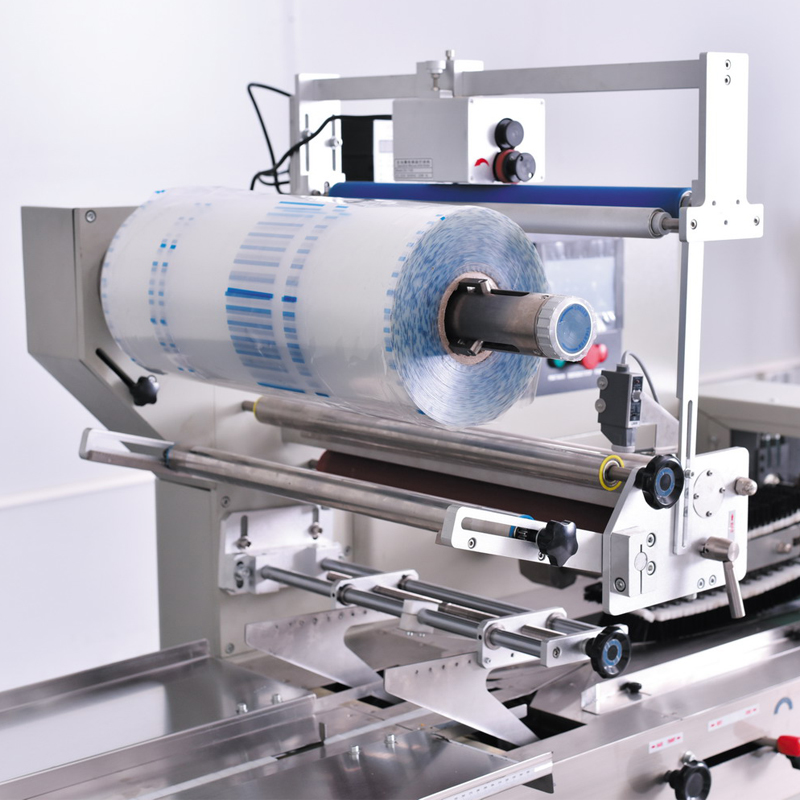

Downward paper pillow packaging machine: it means that the packaging film roll is below the reference level of the packaging machine (that is to say, the packaging film is below the transverse sealing and cutting knife). Suitable for soft, long and loose objects such as towels, paper towels, tableware, cutlery, toys, hardware, daily chemicals, cards, vermicelli, egg rolls, sausages, squid, popsicles, fudge, biscuits, fresh fruits, etc. package of

The reciprocating chocolate packing machine price cuts the packaging film by moving the transverse sealing knife up and down under the action of compressed air to complete the packaging.

To judge whether to use a vertical packaging machine or a horizontal packaging machine, the first thing to consider is whether the packaged product is a powder granule or a single individual. If it is a powder granule, it can basically be concluded that a vertical packaging machine is used. On the contrary, a pillow-type packaging machine is used.

Advantages of the chocolate packing machine

1. The double frequency converter controls the bag length and can be set and cut immediately, no need to adjust the idling, and it can be done in one step, saving time and film.

2. Human-machine interface, parameter setting is convenient and quick.

3. Fault self-diagnosis function, fault display is clear at a glance.

4. High-sensitivity photoelectric eye color mark tracking, digital input sealing and cutting position, so that the sealing and cutting position is more accurate.

5. Temperature independent PID control, suitable for various packaging materials.

6. Positioning stop function, no sticking to the knife, no waste of film.

7. The transmission system is simple, the work is more reliable, and the maintenance is more convenient.

8. All controls are realized by software, which is convenient for function adjustment and technical upgrade, and never falls behind.

Application of the chocolate packing machine

chocolate packing machine is loose rounded granules in the food, chemical and other industrial. Such as: puffed granules, peanuts, popcorn,melon seeds, rice, pepper, sugar,salt, biscuits etc.

chocolate packing machine of video

Description about the chocolate packing machine

| Model | SH-250XB |

| Film width | Max.240mm |

| Bag length | 65-190mm |

| Bag width | 30-110mm |

| Product height | Max.60mm (According to customers’ product size) |

| Film roll diameter | Max.320mm |

| Packing speed | 40-230bag/min (Actual speed depends on customer’s product size and packaging material) |

| Power | 220V,50/60HZ,2.4KW |

| Machine size | (L)3770mm(W)670mm (H)1450mm |

| Machine Weight | About 600kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

chocolate packing machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our Customer Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.