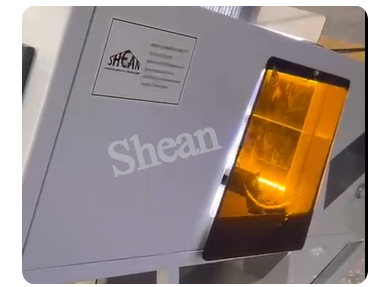

Color Sorter Machine

A color sorter machine, also known as an optical sorting machine, is an advanced equipment widely used in food processing, agricultural, and industrial applications. It utilizes high-resolution cameras and sensors to detect differences in color, shape, and quality of raw materials. By analyzing these features, the machine automatically separates defective or unwanted items from high-quality products with high precision.

The sorting process works by feeding materials into the machine, where they pass through an optical detection system. If the system detects impurities or defective products, the machine uses compressed air or mechanical ejectors to remove them instantly.

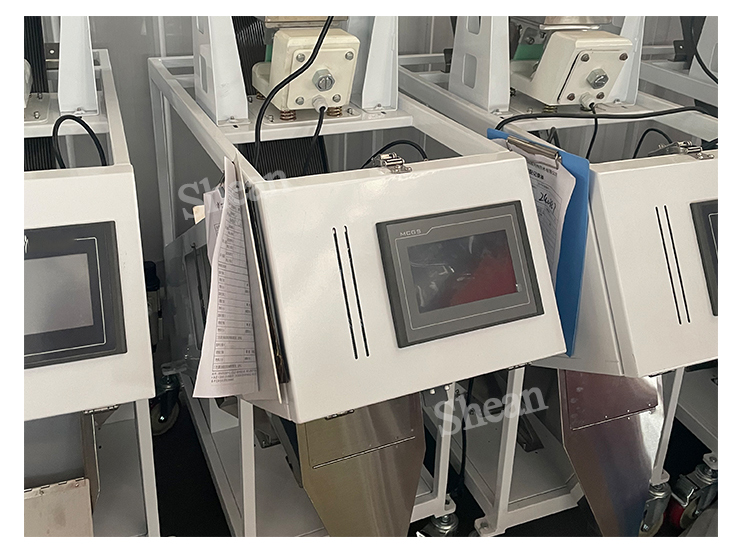

Key Features:

High sorting accuracy with advanced CCD or infrared sensors.

Intelligent software for precise defect detection.

High-speed sorting to improve efficiency and reduce labor cost.

Applicable for grains, rice, beans, nuts, plastics, minerals, and other bulk materials.

Stable performance with easy operation and maintenance.

Applications:

Color sorter machines are widely applied in food processing industries (rice mills, nut processors, coffee beans, seeds) as well as non-food industries (plastic recycling, minerals, chemicals). They improve product quality, ensure food safety, and increase production efficiency.