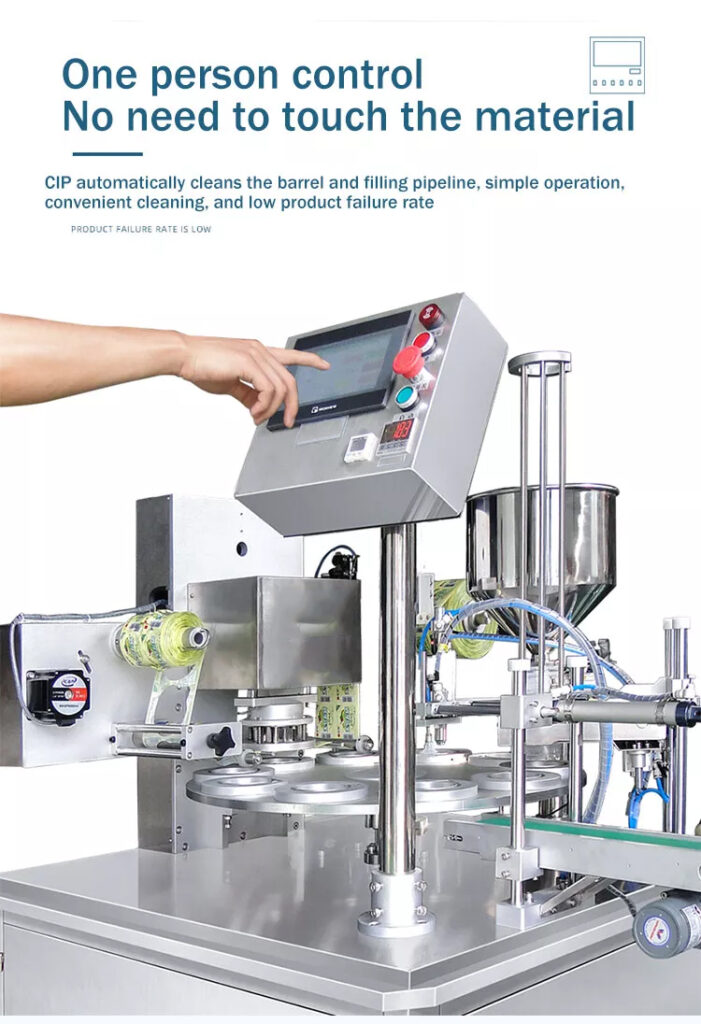

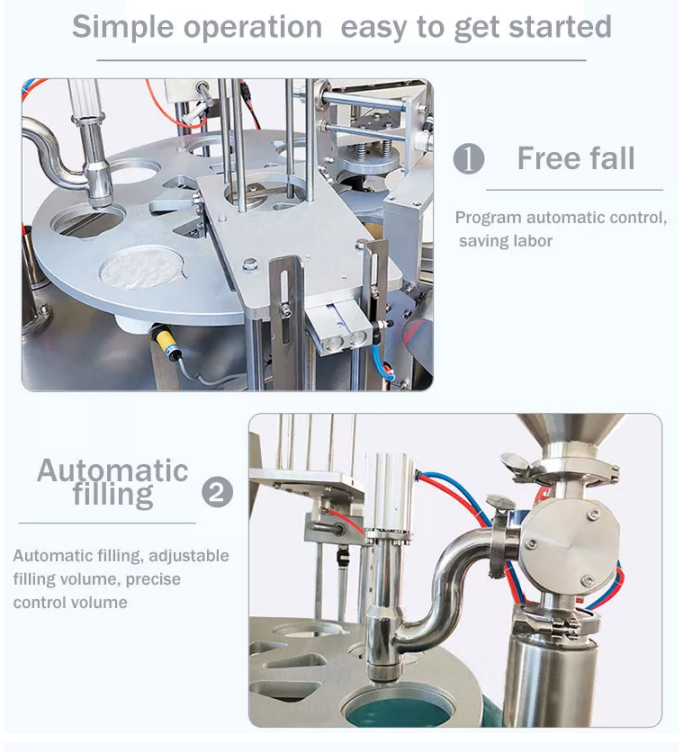

Cup filling and sealing machine is the a fully automatic cup filling and sealing machine , which can automatically pour cups through the bottom controller and various pneumatic electronic accessories.

The cup filling sealing machine is the most efficient cup filling and sealing machine. It adopts piston piston type filling system.The piston type filling system has high precision and good sealing performance. The rotary cup filling and sealing machine is suitable for various viscous materials and is widely used in food, daily chemical and other industries. It is an ideal filling and sealing equipment for cup/box products.]

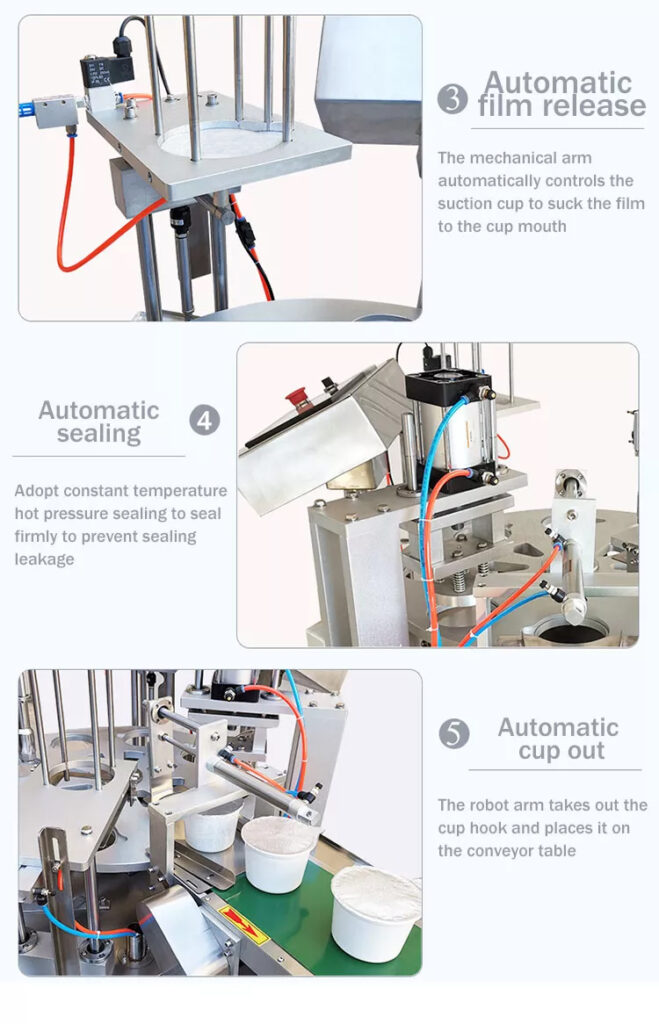

The automatic cup filling and sealing machine is suitable for automatic filling and sealing of plastic cups and plastic boxes. Used for packing mung bean paste, eight-treasure porridge, red bean paste, etc. Fully automatic operation, automatically complete cup dropping, filling, ultraviolet sterilization, photoelectric tracking, date printing, sealing, edge trimming, etc. The machine is made of steel and stainless steel, with simple structure and easy operation.

And the barrel is equipped with a stirring device. The machine can be designed according to the needs of customers. This machine is suitable for filling and sealing various plastic cups, bowls and other materials, heat sealing and trimming with plastic composite film or aluminum-plastic composite film, such as dried fish, fungi, golden shellfish, milk and other boxed products. Loved by people all over the world, the packaged product has a beautiful appearance and a strong three-dimensional effect. This machine is novel in design, simple and reasonable in structure, easy to operate, and ideal in packaging effect. The external material is made of stainless steel and aluminum alloy, which meets hygienic requirements and is especially suitable for small and medium-sized enterprises

Cup Filling and sealing Machine Application

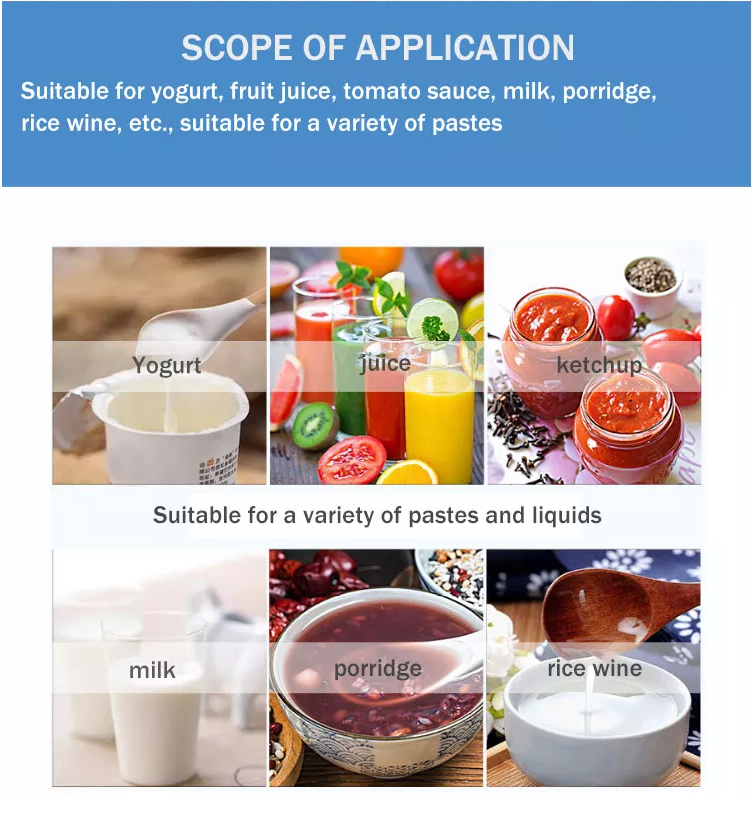

This filling and sealing machine is suitable for the automatic packaging of liquid paste granules, powders and other products in cups for a variety of products:

Cup sauce: such as mineral water, yogurt, fresh milk, jelly, juice, milk tea, seasoning sauce, sweet sauce, etc.

Cup grains: such as popcorn, peanuts, rice, candy, etc.

Cup powder: such as coffee powder, flour, coconut flour, etc.

Tips: Rotary Cup Filling and Sealing Machine In addition to the basic filling and sealing functions of this machine, other functions can be increased or decreased according to requirements, and cup boxes of various sizes can be customized!

Cup filling and sealing machine video

Parameters about Cup Filling and sealing Machine

| Model | GCCS-800 |

| Packing speed | 2000C/H |

| Voltage | 220V/380V |

| Power | 1.2KW |

| air pressure | 0.5MPa-0.75 MPa |

| Maximum air consumption | 0.45m3/m |

| Size | 120*120*170 cm |

| Weight | 380KG |

Our company

Shean is a professional manufacturer of various filling machines.Rooted in filling machine industry for more than 20 years. We have full production experience, advanced technology and constantly updated products. Enjoy a high reputation among users.

Our company meets the needs of customers with technical innovation and attention to the reliability of overall performance. Shean’s main products are varies of filling and packing machines.

For the highest goal we are pursuing, we provide customers with turnkey projects such as design, manufacture, installation and commissioning, after-sales service and technical training for engineering projects.

We share the latest technology with you and provide the service, your trust is our aim.

Cup filling and sealing machine Packing & Shipping

The inside of the package is wrapped with plastic film, and the outside uses an export wooden box. The wooden box meets the export standards, and the fumigated wooden box is anti-insect and moisture-proof, which can also reduce customs difficulties.

Our Customer Reviews

Shean company focuses on machine sales and service for 10+ years. We not only provide customers with complete machine solutions, but also focus on helping to solve installation and debugging problems! Customer satisfaction is our pursuit.