Cup filling and sealing machine is the a fully automatic cup filling machine , which can automatically pour cups through the bottom controller and various pneumatic electronic accessories.

- UV sterilization (optional),

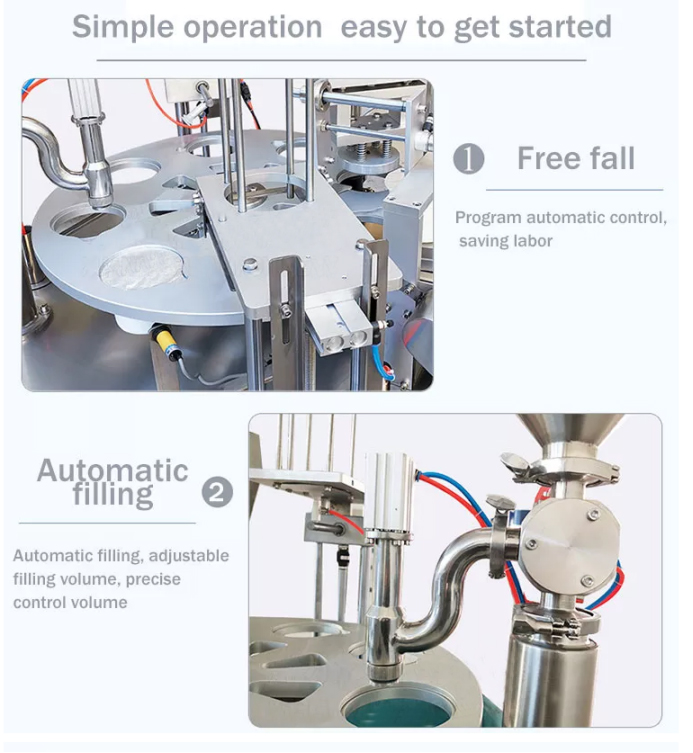

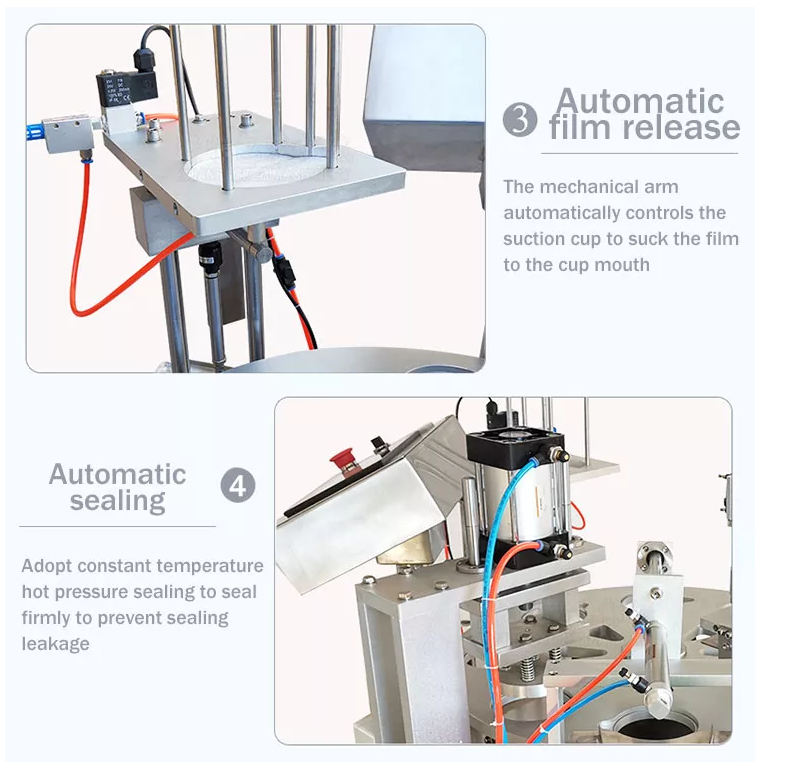

- Auto fill,

- Self-sealing,

- Automatic stopwatch (optional),

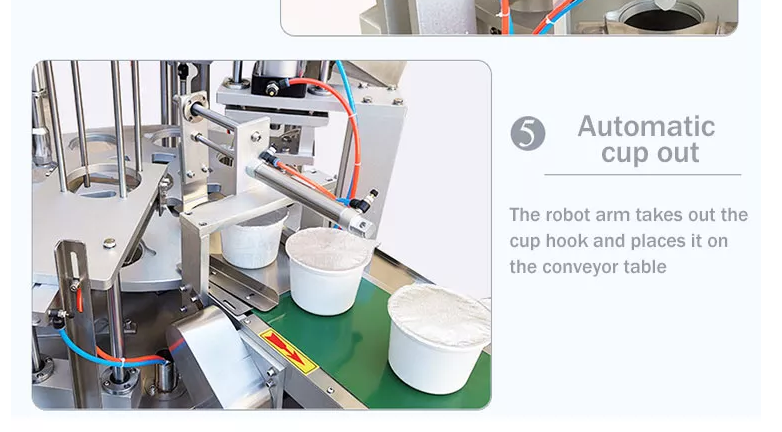

- Automatic sealing (optional); finished products are automatically sent to the assembly line to achieve mass production.

The cup filling sealing machine is the most efficient cup filling machine. It adopts piston piston type filling system.The piston type filling system has high precision and good sealing performance. The rotary cup filling machine is suitable for various viscous materials and is widely used in food, daily chemical and other industries. It is an ideal filling and sealing equipment for cup/box products.

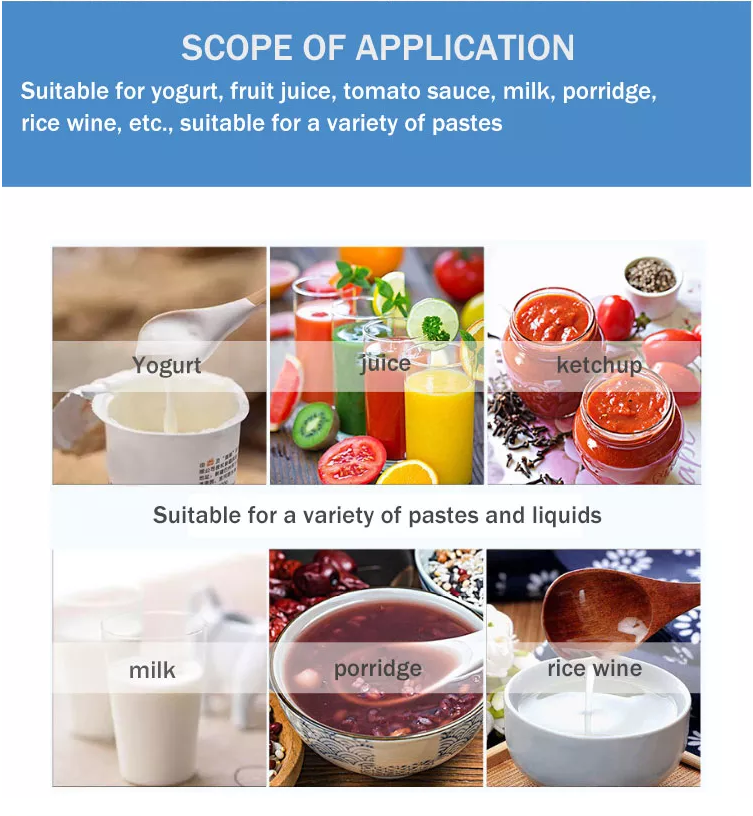

It suitable for all kinds of yogurt, milk, juice drinks, jelly, seasoning and other products production. The design of the machine draws lessons from the advantages of similar equipment at home and abroad, the feedback of domestic users after long-term use of the situation of serious analysis and summary, using in recent years the development of electromechanical automatic control technology of new achievements, the type of equipment optimization design. It mainly has the following characteristics and advantages

(1) The equipment adopts stainless steel frame, which fully meets the hygienic requirements of liquid food production.

(2) The servo motor is used as the power of the transmission mechanism, which makes the motion positioning of each station of the machine more accurate and the operation more stable.

(3) The motor is used as the power of punching shear, and the combined punching shear die is designed. Not only is the action of the shearing mechanism completely consistent, but the consumption of compressed air during operation is reduced by 40%.

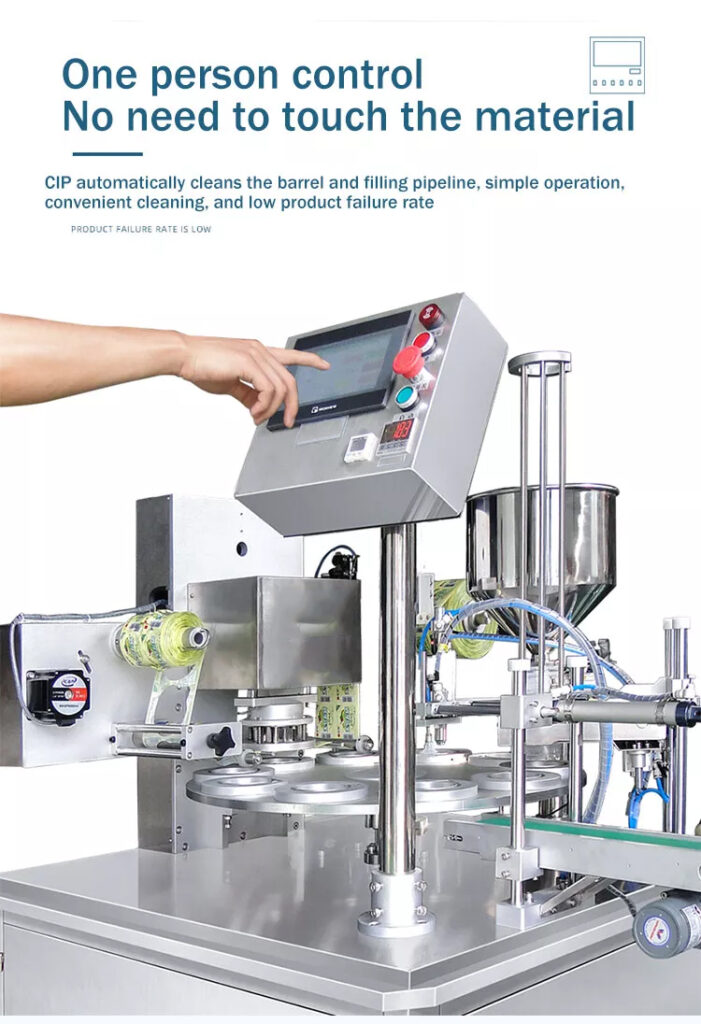

(4) The use of imported PLC control system and modules, complete control and protection functions, operating system using touch screen operating system, can be online parameter Settings and a variety of information display and exchange, to achieve real human-computer interaction.

(5) Filling system adopts pneumatic double way check valve, simple structure, stable performance, easy maintenance, no spatter, no leakage. Equipped with CIP automatic cleaning device.

Cup Filling Machine Application

This filling and sealing machine is suitable for the automatic packaging of liquid paste granules, powders and other products in cups for a variety of products:

Cup sauce: such as mineral water, yogurt, fresh milk, jelly, juice, milk tea, seasoning sauce, sweet sauce, etc.

Cup grains: such as popcorn, peanuts, rice, candy, etc.

Cup powder: such as coffee powder, flour, coconut flour, etc.

Tips: Rotary Cup Filling and Sealing Machine In addition to the basic filling and sealing functions of this machine, other functions can be increased or decreased according to requirements, and cup boxes of various sizes can be customized!

Cup filling machine video

Parameters about Cup Filling Machine

| Model | GCCS-800 |

| Packing speed | 2000C/H |

| Voltage | 220V/380V |

| Power | 1.2KW |

| air pressure | 0.5MPa-0.75 MPa |

| Maximum air consumption | 0.45m3/m |

| Size | 120*120*170 cm |

| Weight | 380KG |

Our company

Shean is a professional manufacturer of various filling machines.Rooted in filling machine industry for more than 20 years. We have full production experience, advanced technology and constantly updated products. Enjoy a high reputation among users.

Our company meets the needs of customers with technical innovation and attention to the reliability of overall performance. Shean’s main products are varies of filling and packing machines.

For the highest goal we are pursuing, we provide customers with turnkey projects such as design, manufacture, installation and commissioning, after-sales service and technical training for engineering projects.

We share the latest technology with you and provide the service, your trust is our aim.

Piston filling machine Packing & Shipping

The inside of the package is wrapped with plastic film, and the outside uses an export wooden box. The wooden box meets the export standards, and the fumigated wooden box is anti-insect and moisture-proof, which can also reduce customs difficulties.

Our Customer Reviews

Shean company focuses on machine sales and service for 10+ years. We not only provide customers with complete machine solutions, but also focus on helping to solve installation and debugging problems! Customer satisfaction is our pursuit.