Edible oil filling machine can be divided into semi-automatic filling machines and automatic filling machines according to the degree of automation, and can be divided into double-head semi-automatic edible oil filling machine according to its function.

Semi-automatic edible oil filling machine: Semi-automatic filling machines are generally equipped with a foot switch, quantitative → put barrels → foot pedal start → oil nozzle drop → filling → oil nozzle recovery → vacuum suction → put down a group of empty barrels.

The semi-automatic filling machine is divided into single head and double head, the filling capacity of single head is 120 barrels/hour (calculated by 5 liters). Double-head small package filling capacity: 360 barrels/hour (calculated by 5 liters).

Automatic edible oil bottle filling machine: Automatic filling machine process: manual quantitative → manual bottle release → automatic sensing of the position of the bottle mouth position, nozzle drop → automatic filling → automatic transmission → manual capping → automatic capping → automatic coding → conveyor belt warehouse ( This process only requires two manual operations: manual bottle placement and manual cap placement, and unmanned filling can also be realized.)

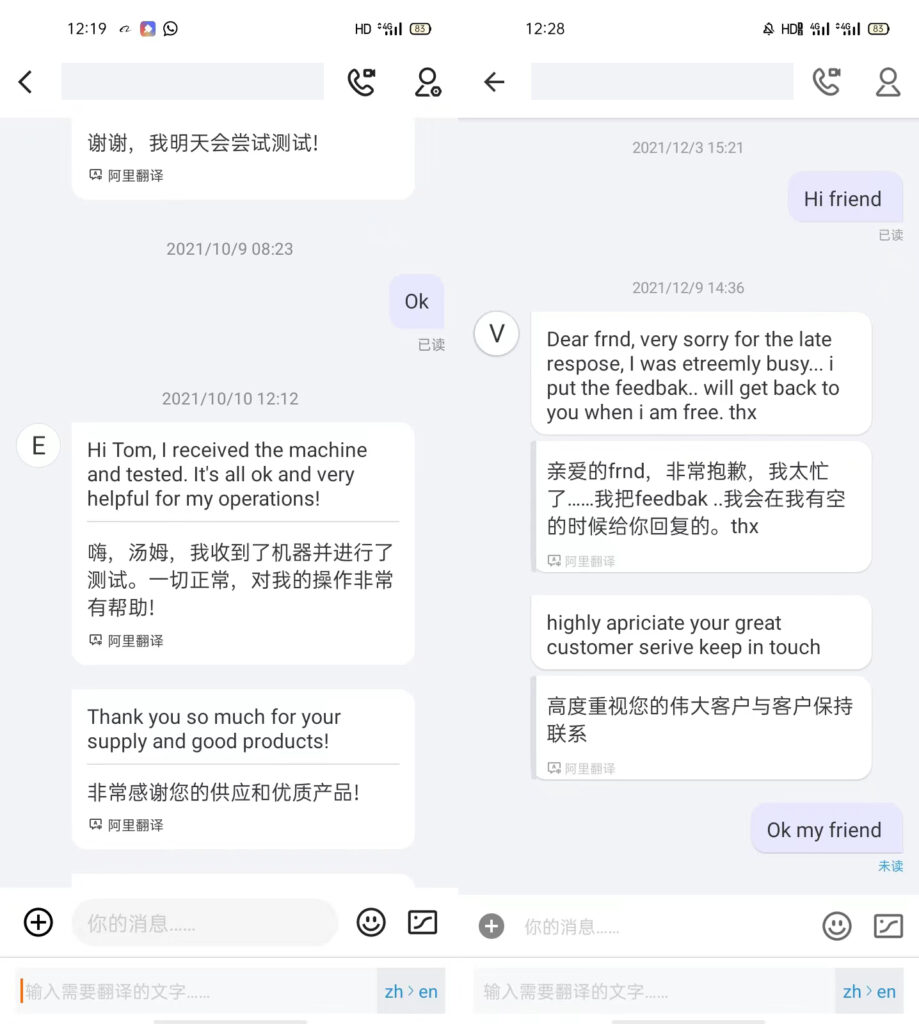

As a manufacturer focusing on machine production and sales, our machines are sold to customers all over the world, and we have also received numerous returns from customers, proving that the quality of our machines is trustworthy, but the question often asked by new customers is, if the machine is broken what to do. Because the machine is broken, it means that the customer will stop production and there is no profit, so this is a problem that everyone cares about. I will give you a detailed answer here.

First of all, before producing the machine, we will repeatedly confirm the parameters with the customer to ensure that the manufactured machine can meet the customer’s requirements. Then, after the machine is produced, we will conduct a video inspection with the customer to test whether the machine can work normally. Then the machine is packed and loaded into the car, and a video will be sent to the customer, so that the customer can know the movement of the machine at any time. With the machine, we will provide some wearing parts. If these parts are damaged during use, customers can replace them by themselves. If the customer receives the machine and the machine fails to work properly at any stage of use, he or she can contact us 24 hours a day, and then professional technicians will guide the operation through video.

We are very confident in the aspect of later guarantee, so we have also won praise from many customers in this aspect.Thus,edible oil filling machine price is not the most important issue,but service is.

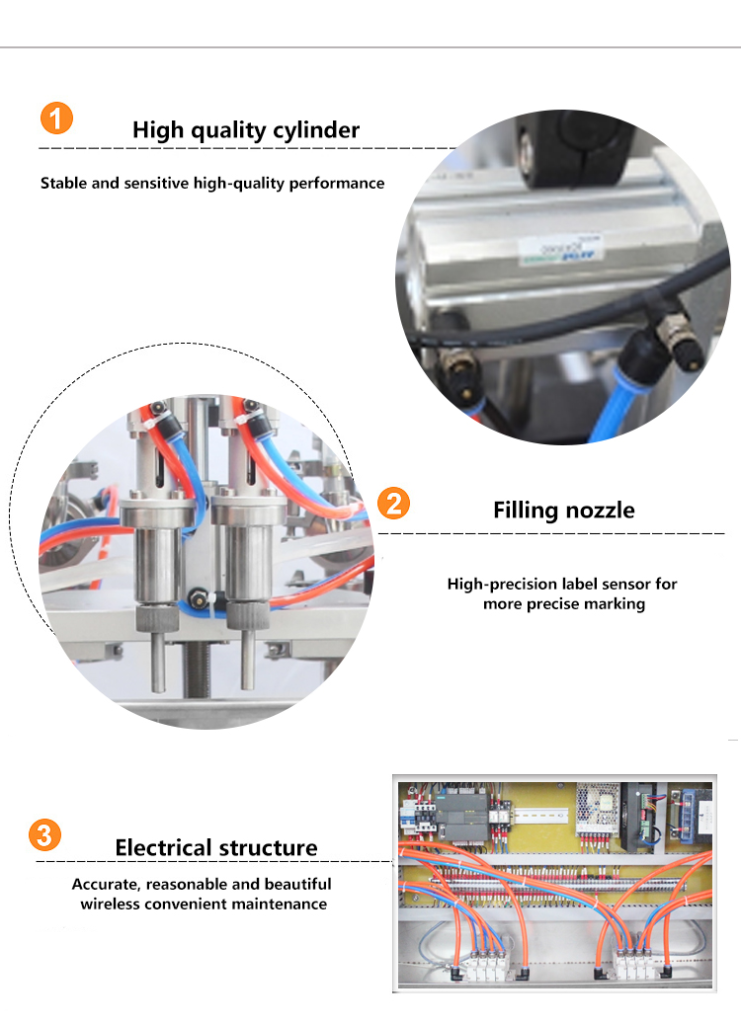

Pictures of the machine and detail parts

Advantages of the Edible Oil Filling Machine

- This machine equips with stable and sensitive high-quality performance.

- The high-precision label sensor can be use for more precise marking.

- The electrical structure is accurate,reasonable and beautiful,it is wireless convenient maintenance.

Edible Oil Filling Machine features:

Application Picture

The liquid filling machine is mainly applicable to the food and beverage industry, such as the filling of milk, juice, and wine; the pharmaceutical industry, such as the aseptic filling of vaccines, oral liquids, and injections; and the daily chemical industry, such as liquid cosmetics, laundry Liquid filling, etc.

Description about Edible Oil Filling Machine

| Item | Description |

| Power | 500W |

| Power supply | AC220/110V 50/60HZ |

| Air pressure | 0.4-0.6Mpa |

| Speed | 5-60 bottles/min |

| Accuracy | ±1% |

| Model | 10-100ml 30-300ml 50-500ml 100-1000ml 500-3000ml 1000-5000ml |

| Number of filling heads | 2、4、6、8、10 (design for customers) |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.