As we all know,the single filling machine price is very easy to offer,but when you want to equip the whole line,you should add the filling machine price with the other machines.What’s more,the filling line is so complicated as its production process to all of our customers,specially for the ones who is just opening a new business or industry.So please let me introduce the each process.Today we will choose the fluid material for example.

The fluid filling line is generally used for cleaning, filling, capping, labeling, coding, etc. of various liquids, pastes, semi-fluid and other materials.The fluid filling lines are generally divided into three types: rotary type, linkage type and linear type.

The cleaning part is designed with different cleaning machines according to different bottle shapes, generally including chain rail type, rotary backflushing type, air blowing type, etc. Customers must choose the most satisfactory washing machine according to their bottle shape.

In the filling part, according to different materials, the liquid is usually measured by direct current or pumping type; the paste is usually measured by piston pressure type; and the material containing granular materials is measured by screw type. According to the different requirements of materials, filling methods such as aeration, vacuum, negative pressure and normal pressure can be used.

For the cover part, there are various types of covers, and the molds of the models are also different. The popular bottle caps are roughly as following: threaded caps, anti-theft caps, three or four screw caps, beer caps, duckbill caps, nozzle caps, and other special-shaped caps. The automatic capping machine is also divided into automatic capping machine, automatic capping machine, automatic capping machine, etc. due to different bottle caps. Due to production and technical issues, there are also semi-automatic capping machines, capping machines, and can sealing machines.

The labeling part is based on the material and requirements of the label, and the most popular in the world are generally four types of self-adhesive labeling machines, hot-melt adhesive labeling machines, paste labeling machines and sleeve labeling machines. General beverage bottles are mostly found in sleeve labeling machines and hot melt adhesive labeling machines, while ordinary bottles are mostly found in self-adhesive labeling machines and paste labeling machines for special glass bottles.

The marking part is also divided into different types, there are ribbon coding machines (often equipped with labeling machines), ink coding machines (used alone or matched), and inkjet printers (used independently). Marking machines are generally used in date coding, serial number marking, origin marking, etc.

Above all,the most important thing is the material.Once a customer comes to us to ask about the filling machine price,the first question is always about which material you need to fill.Because as i said before,liquid filling machine price is normally lower than the paste bottle filing machine price.After we figure out which type of the filling machine suits your material,then we can discuss other machines.

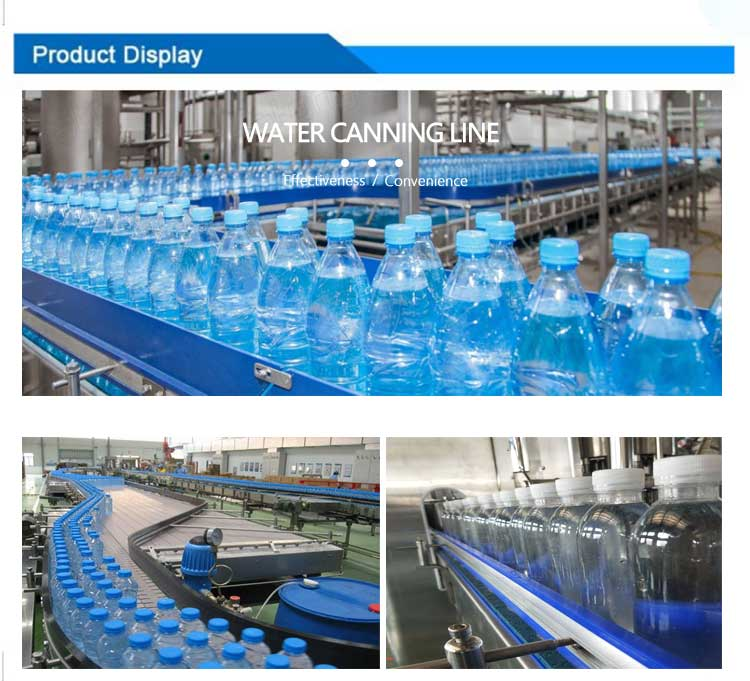

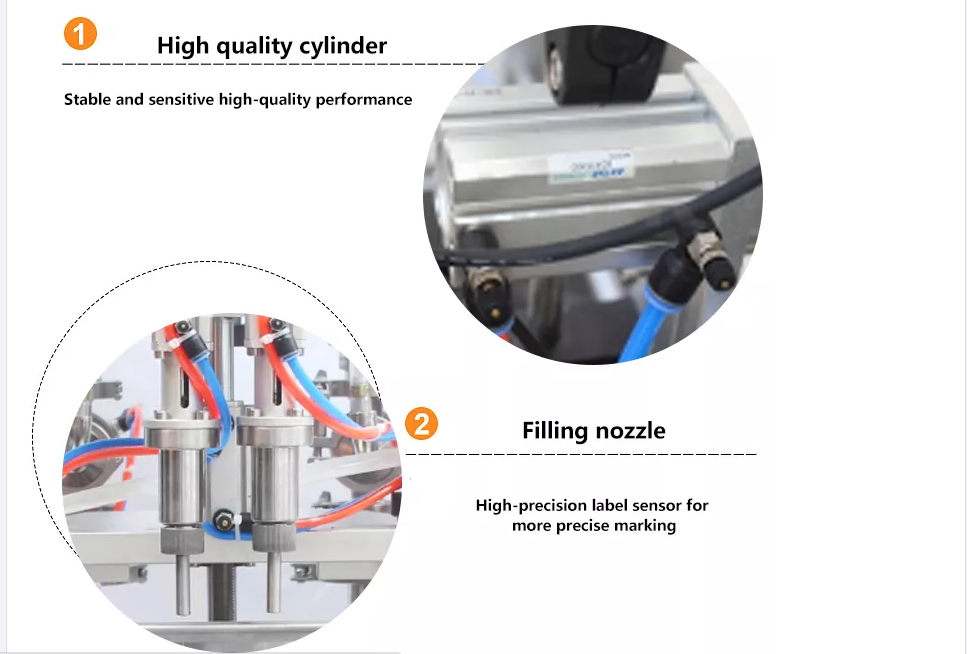

Pictures of the machine and detail parts

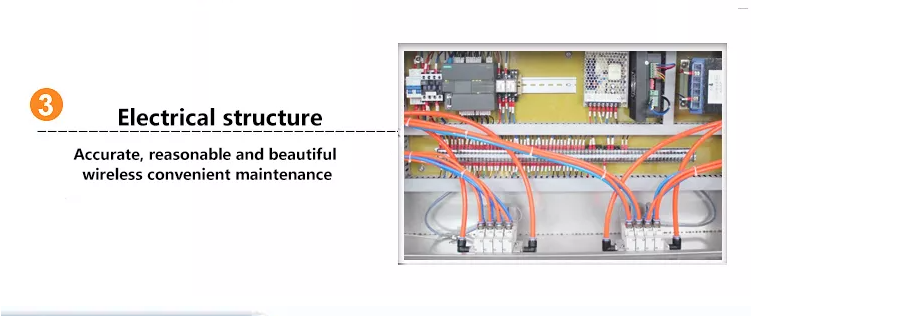

Advantages of the Filling Machine Line

1.The cylinder of the machine has very high quality which equip with stable and sensitive high-quality performance.About the filling nozzles,we use high-precision label sensor for more precise marking.

2.The electrical structure has accurate,reasonable and beautiful wireless convenient maintenance.

Filling Machine features:

Application Picture

- The mineral water production line use direct connection technology between air conveyor and in-feeding star-wheel to substitute in-feeding screw and conveyor to ease the process of bottle-size-changing.

- Neck-hanging technology is applied in bottle transportation of the automatic water filling machine. Instead of traditional star-wheel, we use neck-hanging gripper to make bottle-size-changing easily , without equipment height adjustment ,only arch board and star-wheel such little nylon parts need to be changed.

- Specially-designed rinsing grippers which are made of stainless steel are firm and endurable, with no contact to screw part of the bottle to prevent second pollution in this automatic water filling machine.

- Rapid gravity filling valve with high flow makes filling faster with accurate liquid level and without any liquid loss.

5. Splint of star-wheel using twist descending way to simplify the process of bottle-size-changing.

Filling Machine Line video

Description about Honey Filling Machine

| MODEL | YIELD(BPH) | INSTALLED CAPACITY(KW) | OVERALL DIMENSION | WEIGHT(KG) |

| 8-8-3 | 2000-2500 | 3.13KW | 2400*1670*2350 | 2500 |

| 12-12-4 | 3000-3500 | 3.84KW | 2470*1970*2350 | 3000 |

| 18-18-6 | 5000-6000 | 3.84KW | 2865*2170*2350 | 4000 |

| 24-24-8 | 8000-10000 | 5.6KW | 3700*2570*2350 | 5000 |

| 32-32-10 | 12000-14000 | 6.3KW | 3800*2950*2400 | 6000 |

| 40-40-12 | 16000-17000 | 7.3KW | 4500*3400*2400 | 7000 |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

This is one of my previous customers who bought a sealing machine, but some accessories were lost due to the installation problem of the workers during use. The first time the customer told me, I helped the customer re-issue the accessories he needed. Solved his problem as quickly as possible, allowing him to continue to produce smoothly, so he is very grateful to me.As we always said,we are not just a machine manufacturer and seller,we are also your friends to help you solve all the technical problem and help you with your production problem.

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.