Today I want to talk about the problem of maintenance of the flow wrap machine. Our company focuses on solving all technical problems for customers in the shortest time, and solving all machine-related problems for customers. But as a user, it is always beneficial to know more about troubleshooting. Hope today’s sharing will be helpful for your machine usage,especially to the flow wrap machine.

When the temperature is too high, the speed is too slow, and the heat resistance of the outer layer of the coating is poor, the seal will appear scorched and wrinkled. The maintenance method is to adjust the speed, lower the temperature, and replace the film material.

The second knife seat is too high or too low, the packaging speed of the flow wrap machine is too fast, and when the push rod and the cutter are not synchronized, the cutter will cut on the product. The maintenance method is to reduce the packaging speed and adjust the height of the end sealing parts so that the center of the sealing knife is in the middle of the product height.

The color of the film color mark is too light, the film drive is slippery, and the cutting position will deviate from the color mark when the color mark tracking is not turned on. At this time, the maintenance method is to refer to the manual of the flow wrap packaging machine and adjust its sensitivity; in the man-machine dialogue interface, switch the tracking mode to “tracking cut”.

If the air pressure is wrong, the cylinder swing rod is loose, the heating temperature is low, and the heat-pressing roller and the transmission roller are not parallel, there will be poor heat sealing. The maintenance method is to adjust the parallelism, adjust the temperature and air pressure to tighten it.

The solid-state circuit breaker is burned out, the temperature control meter is damaged, and the thermometer cannot control the temperature when the capacitor is damaged. The maintenance method of this horizontal flow wrap machine is to replace the galvanic couple, replace the temperature control meter, and replace the heating element.

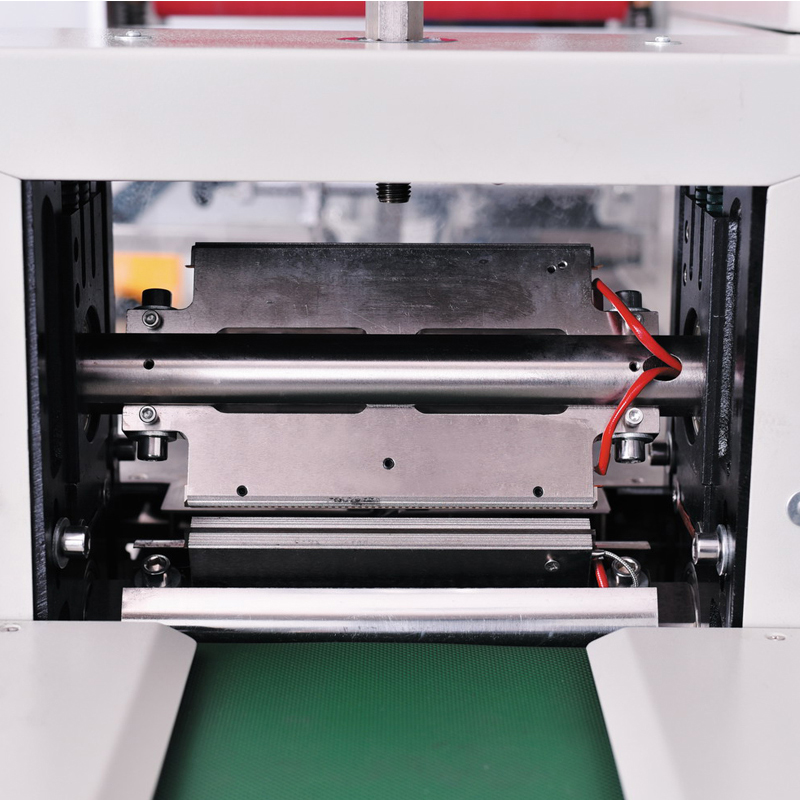

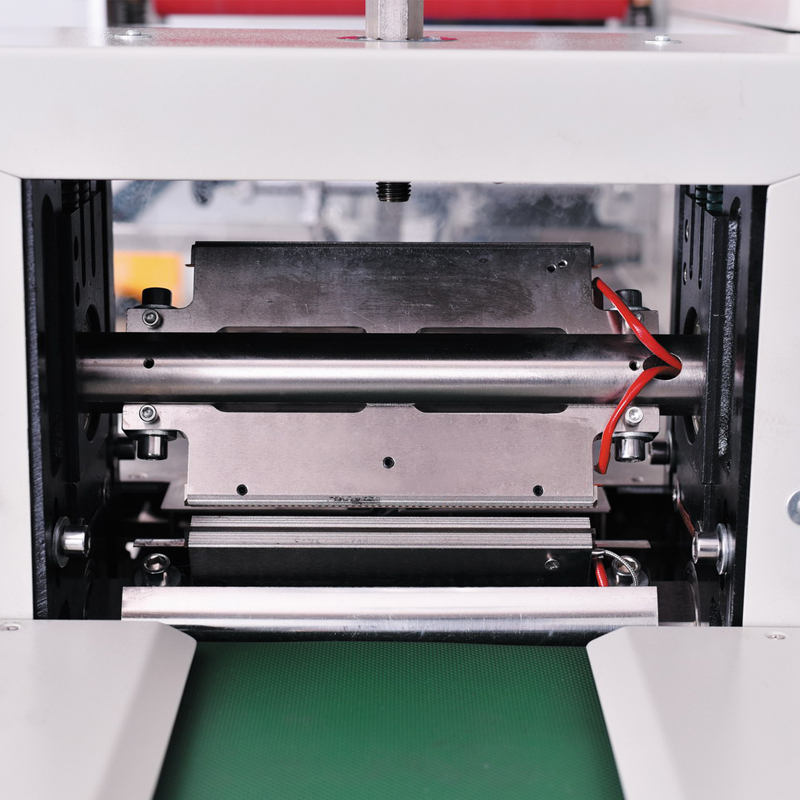

Pictures of the machine and detail parts

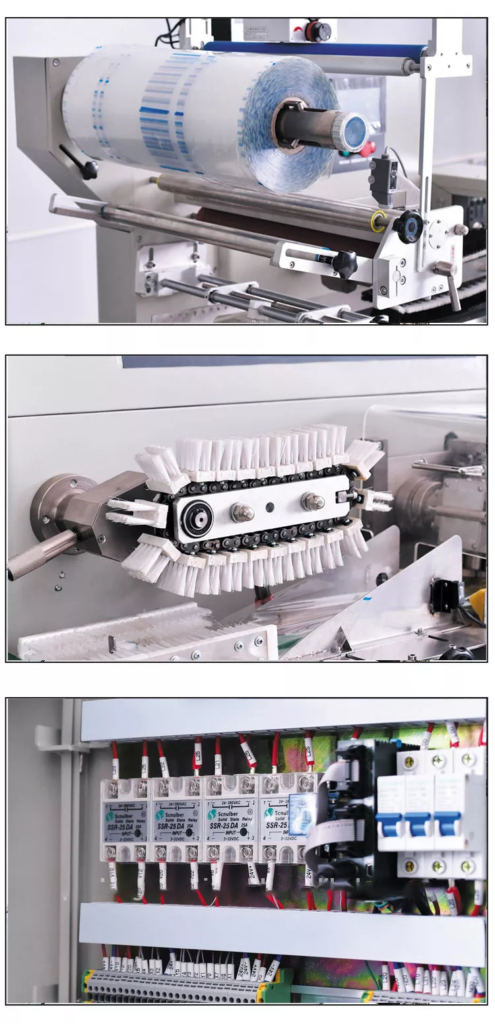

Advantages of the Flow Wrap Machine

- The machine uses Chinese and English display screen control system,which makes it has convenient operation,automatic matching of control system and improving efficiency.

- The linked film rolls coordinate the entire film drawing process,which is suitable for more roll film materials and makes film drawing smoother.

- Intelligent temperature controller control,automatically complete measurement bag making,filling,sealing,printing batch number.

- The machine equips with stainless steel material,accurate sealing beautiful bag making,to meet your needs with heart.

Flow Wrap Machine features:

This flow wrap machine is suitable for food industry, pharmaceutical industry, daily necessities, disposable products, hardware products, plastic products, toy stationery, industrial supplies, industrial parts, auto parts.

Description about Flow Wrap Machine

| Model | LT-250B/D | LT-320B/D | LT-350B/D |

| Film width | Max.250mm | Max.320mm | Max.350mm |

| Bag length | 65-190mm | 65-190mm | 65-190mm |

| Bag width | 30-110mm | 30-110mm | 50-160mm |

| Product height | Max.40mm | Max.40mm | Max.45mm |

| Film roll diameter | Max.320mm | Max.320mm | Max.320mm |

| Packing speed | 40-230bags/min | 40-230bags/min | 40-230bags/min |

| Power Specification | 220V,50/60Hz,2.4kw | 220V,50/60Hz,2.4kw | 220V,50/60Hz,2.4kw |

| Machine size | 3770*670*1450mm | 3770*670*1450mm | 3770*670*1450mm |

| Weight | 500kg | 500kg | 500kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.