- PRODUCT DETAIL

Beer Can Filling Machine

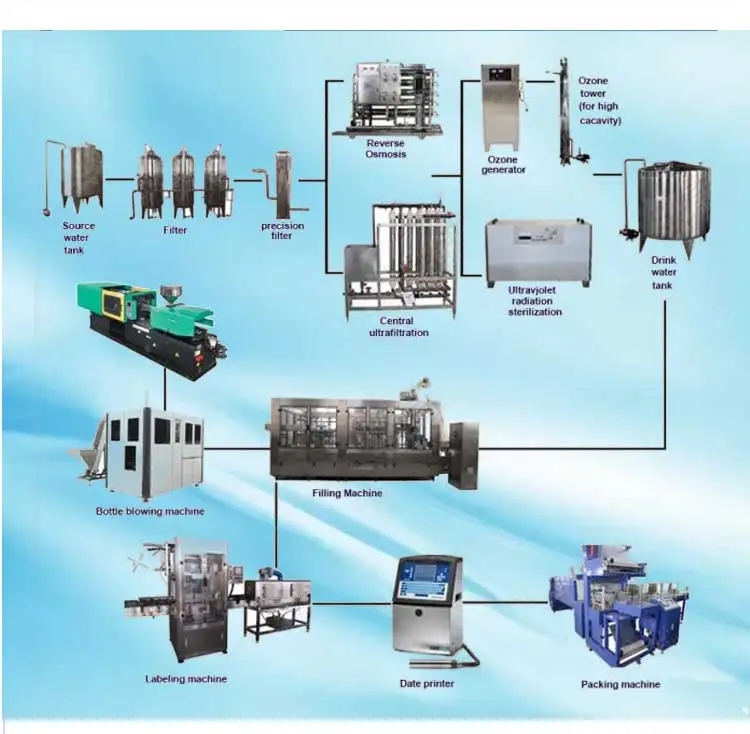

The beer can filling machine is a high-performance solution designed for efficient, accurate, and hygienic filling of beer into cans. Built with advanced technology, it ensures precise liquid levels, minimal foam generation, and consistent sealing quality to maintain the freshness and carbonation of the beer.

This machine integrates filling and sealing functions in a compact linear or rotary system, making it suitable for both craft breweries and large-scale beer production lines. It features stainless steel construction for durability, easy cleaning, and compliance with food-grade standards.

With adjustable speed, automatic control, and compatibility with different can sizes, the beer can filling machine provides a reliable and cost-effective solution for modern beverage packaging operations.

Main Structure: 1. Rinsing system: Combined with rotary tray with clamp, water distributing tray, water tank and rinsing pump. 2. Filling system: Combined with hydraulic, filling valve, controlling ring, and elevator-cylinder. 3. Capping system: Combined with capper, cap sorter and cap falling track. 4. Driving system: Combined with main motor and gears. 5. Bottle transmitting system: Combined with air conveyor, steel starwheels and neck supporting carrier plates. 6. Electrical controlling system: this part is frequency inverted, PLC controlled and touch screen operated.

Washing Part

1.Into bottle way is air conveyor direct connection with Bottle dial .

2.All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean .

3.304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing

4. 304/316 stainless steel washing pump make the machine more durable .

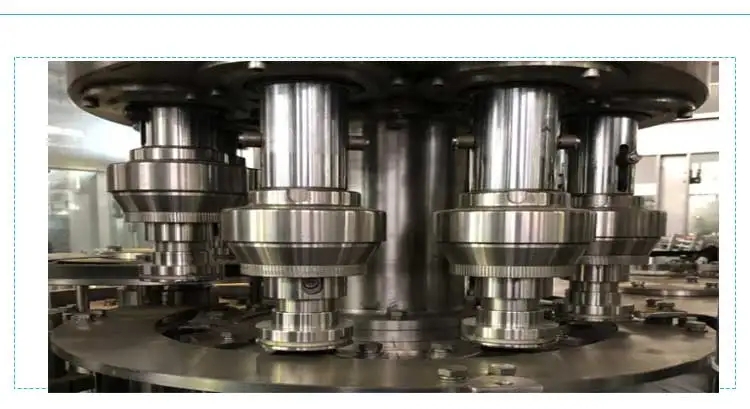

Filling Part

1.During filling juice ,we will make a cover installed on the filling valve, avoiding the fruit pulp return inside reflux pipe to block the pipe.

2.Filling valve and bottle lifter uses adopts German Igus bearings which are corrosion-resistant and maintenance-free.

3.By install CIP cleaning cups, the filling machine can realize online CIP cleaning

4.During filling process,there is no reflux of product, avoiding blockage of product.

Capping Part

1.Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping.

2.All 304/316 stainless steel construction 3.No bottle no capping

4. Automatic stop when lack of bottle 5.Capping effect is stable and reliable, Defective rate ≤0.2%