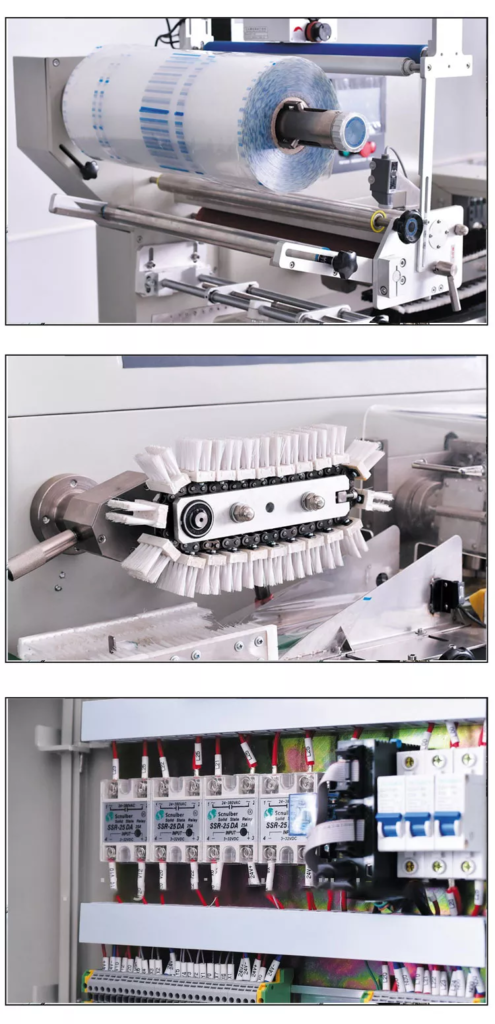

The working principle of the horizontal flow wrap machine 1. The working principle of the food packaging machine The flow wrap packing machine is designed and produced by the domestic leading and most mature and reliable technology, which brings together the essence of many years of experience in the field of horizontal flow wrap machine. This kind of composite packaging film coil is used to package bulk food, which is very suitable for the needs of the majority of users. 1) The electrical part of the automatic packaging machine is generally composed of the following: A) The main control circuit consists of a speed sensorless vector inverter and a programmable logic controller (PLC) to form the control core; B)

The flow pack machine temperature control circuit consists of an intelligent temperature control meter, solid state It is composed of relays, thermocouple elements, etc., with accurate temperature control, intuitive display and convenient setting; C) Multi-point tracking and detection are realized by photoelectric switches, electromagnetic proximity sensors, etc.; 2. The working principle of horizontal flow wrap machine type increases with the degree of automation , The operation, maintenance and daily maintenance of the packaging machine are more convenient and simple, and the professional skills requirements of the operators are reduced. The quality of product packaging is directly related to the temperature system, the speed accuracy of the host, and the stability of the tracking system. The tracking system is the control core of the packaging machine. It adopts forward and reverse bidirectional tracking, which further improves the tracking accuracy. After the machine is running, the film marking sensor continuously detects the film marking (color mark), and at the same time, the tracking microswitch of the mechanical part detects the position of the machine.

3. 2. Advantages of applying frequency conversion speed regulation equipment 1) Simplify the transmission system, greatly reduce the failure rate, and reduce the maintenance cost of enterprises. 2) Increase production and reduce costs. It can improve production technology, improve product output and quality, and effectively save costs and maximize profits. 3) Realize the software of the control and improve the function. 4) Through the functions of torque compensation, stall prevention and restart, non-trip operation is realized; the quality of the produced products is stable and the efficiency is improved.

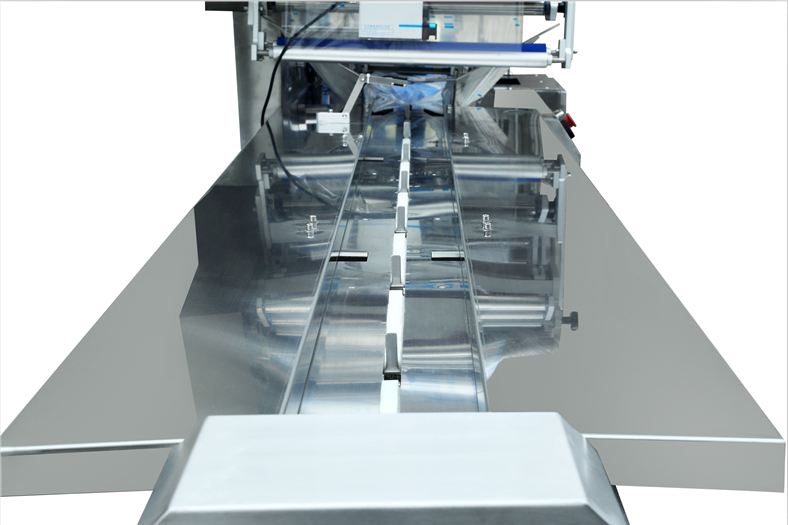

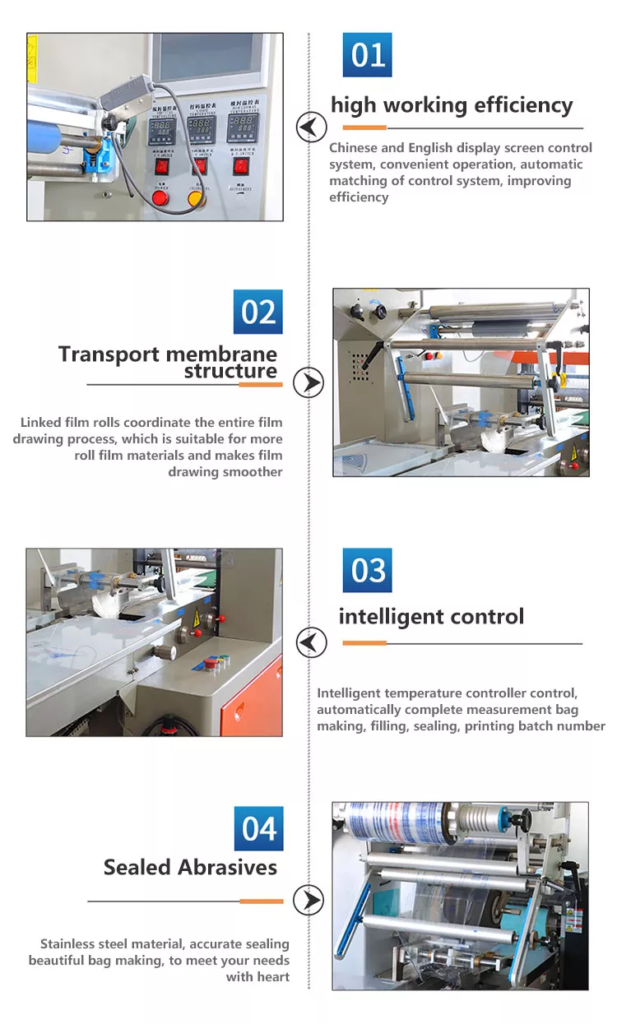

Pictures of the machine and detail parts

Advantages of the Horizontal flow wrap machine

1. The whole machine adopts imported PLC system, humanized operation, simple operation and convenient use

2. The whole line of the machine is made of stainless steel 304, which is rust-proof and corrosion-proof. All accessories are completed by our own CNC lathes and machining centers to ensure the quality of every basic accessory to the whole machine

3. Supported by a strong technical team, the quality of the machine is guaranteed not to be damaged after long-term use, and the high-quality after-sales service can answer various problems encountered by users in a timely manner

Horizontal flow wrap machine features:

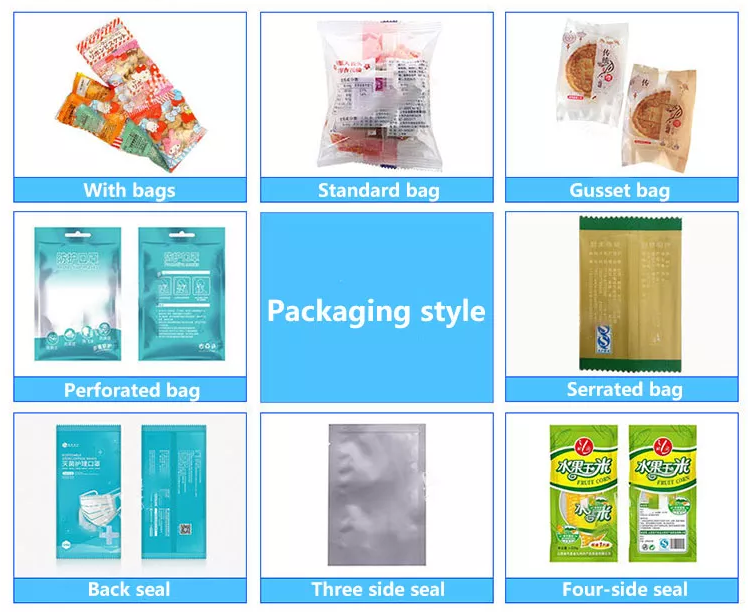

Application Picture

Horizontal flow wrap machine can pack, biscuits, bread, kgf, noodles, hardware accessories, masks, candy, toilet paper

Horizontal flow wrap machine video

Description about Horizontal flow wrap machine

| Film width | Max.240mm |

| Bag length | 65-190mm 120-280mm or 90-220,150-330mm |

| Bag width | 30-110mm |

| Product height | Max.45mm-60mm |

| Film roll diameter | Max.320mm |

| Packing speed | 40-230bag/min |

| Power | 220V,50/60HZ,2.4KW |

| Machine size | (L)3700mm(W)670mm (H)1450mm |

| Machine Weight | About 370kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We focus on the production of various types of packaging machines, powder, granules, bread, cakes, chocolate, candy, hardware accessories, daily necessities, our machines have perfect after-sales service guarantee and high-quality quality assurance, the machines are all imported PLC The controller, the machine performance is very perfect and very intelligent, which greatly saves manpower for the user, and we also provide customized services, which can be customized according to the needs of users

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Horizontal flow wrap machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

This is one of my Saudi Arabian customers who used our machine, greeted me every day and told me that the machine is working very well every day, the machine is really easy to use, and it saves them a lot of manpower