Innovative Carton Filling Machine for Aseptic Juice Packaging is suitable for fresh juice of aseptic packing for long life shelftime

VIDEO

Product Description

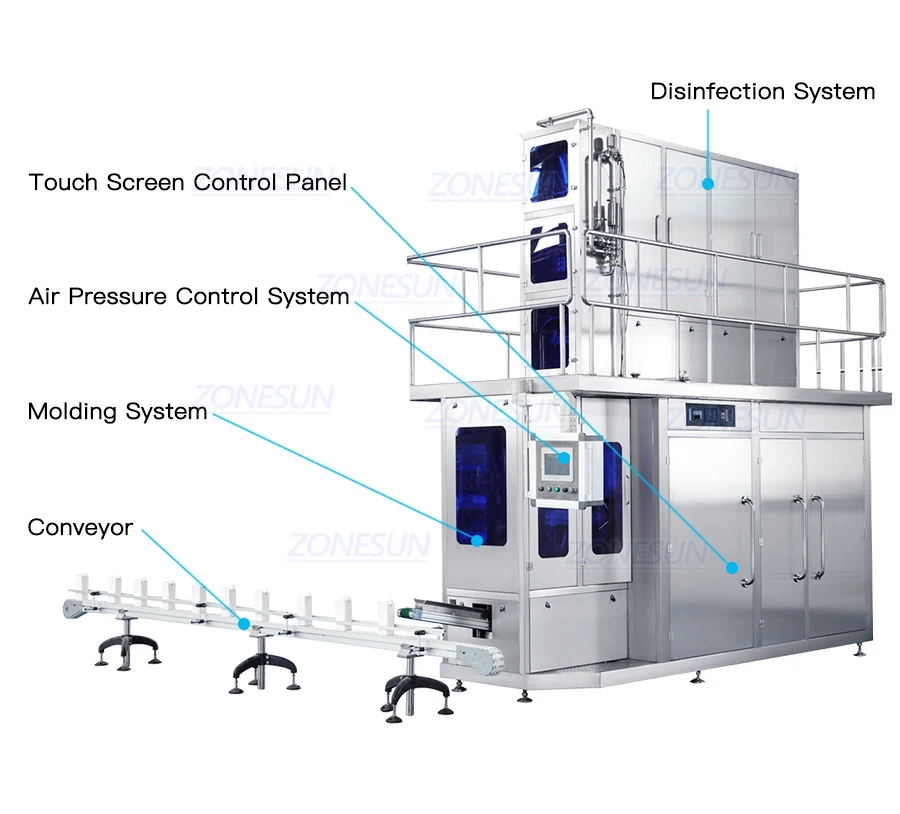

With the touch screen control panel, adjusting the working parameters according to the working status has never been easier. This not only improves the working accuracy but also saves you valuable time and effort.

The molding system of this packaging machine efficiently folds the package material, ensuring a neat and professional finish. The sterilized filling material is then precisely filled, guaranteeing the highest level of hygiene and product quality.

Once the filling process is complete, the carton is seamlessly moved to the cutting process, further streamlining your packaging operations.

Invest in the Shean (Cangzhou) Corp., Ltd. touch screen controlled packaging machine and experience the convenience, accuracy, and efficiency it brings to your packaging process.

Application Scope

Product Description

FUNCTIONS AND FEATURES

The machine is designed for filling milk, juice, soymilk, and other beverages. It automates the entire process, including form feed, sterilization, filling, shaping, and sealing.

The machine is equipped with a PLC human control system and an intuitive Human-Machine Interface that displays in both English and Chinese.

With a low fault rate and easy operation, this machine ensures efficient and hassle-free production.

It automatically completes all job steps, including scroll run, batch numbering, plastic tape sticking, sterilizing, cylinder rolling, material filling, sealing-off, molding, cutting, and horn-shaped formation.

Aseptic Conveying

Aseptic conveying refers to the transportation of sterilized products from ultra-high temperature sterilization equipment to aseptic filling machines. The AP sterile group valve of this machine can be connected to the intermediate conveying pipeline.

After sterilization, the packaging material passes through a *** water tank. The sterilization effect of ***, with a concentration of 35% and heated to around 75 degrees, ensures the packaging material is fully sterilized. According to Tetra Pak’s demonstration design, the packaging material should pass through the *** water tank for at least 6.6 seconds to achieve optimal sterilization. Please note that the sterilization efficiency of *** depends on its concentration, temperature, and time.

Sterile Environment

1.Aseptic conveying is actually the aseptic conveying from ultra-high temperature sterilization equipment to aseptic filling machines. Aseptic conveying requires the middle pipelines and equipment to be able to be disinfected, disinfected, and kept closed. The AP sterile group valve of this machine can be connected to the intermediate conveying pipeline.2. Sterilized packaging materials, please refer to the aseptic system overview diagram below. This machine uses hydrogen peroxide with a concentration of 35%, and when heated to around 75 degrees, the packaging materials pass through the hydrogen peroxide water tank. The sterilization effect of hydrogen peroxide is utilized to sterilize the packaging materials (according to the demonstration design by Tetra Pak, the hydrogen peroxide water tank allows the packaging materials to pass through the hydrogen peroxide water tank for no less than 6.6 seconds, which can fully ensure the sterilization effect of the packaging materials). Note: The sterilization efficiency of hydrogen peroxide is related to concentration, temperature, and time3. Aseptic environment, please refer to the overview diagram of the sterile system below. The air is sterilized at high temperature by an ultra-high temperature heater, cooled, and then enters the sterile room to maintain a certain positive pressure. (From the figure, it can be seen that sterile air is replaced through circulation, which has two functions. One is the replacement of new and old sterile air, and the other is the removal of hydrogen peroxide molecules from the sterile room and their dissolution with water before being discharged into the dilution tank, which is beneficial for environmental protection.) The establishment of a sterile environment can be summarized in three sentences:Use hot sterile air to carry atomized hydrogen peroxide and spray it into a closed area.3.1 The atomized hydrogen peroxide is liquefied and then dried with hot sterile air.3.2 After drying, use cooled sterile air to maintain positive pressure in the sterile room.The above three points can be understood in combination with spray and drying in the next section. In the four stages of aseptic filling, “sterilized packaging materials” and “sterile environment” are achieved by the machine

For more information, please contact Shean (Cangzhou) Corp., Ltd

Company Profile

Our customs

FAQ

1. Can you guarantee your quality if we order on you ?Of course.Best quality is our principle all the time.You can be assured on our production.2.What should I do if we are not able to operatethe the machine when we receive it?Operation manual guides you the installation.Besides, we haveprofessional after-sale groupto customer ‘s site to solve any problems.weprovide 7*24 hours on-line technical support.3.How could I get the spares on machines?We will send extra sets of easy broken spares andaccessories likeo ring etc.Non-artificial damagedspares will be sent freelyduring 1 year ‘s warranty.4.How to maintain such a machine ?Please clean every part after filling thus can givelong using life of machine and make a carefullyclean 3 times a year.5.Anstrallation and Commissioning INSTALLATION and COMISSIONING Two weeks before the equipment is shipped, the seller and the buyer will communicate on the equipment entry conditions, required installation and commissioning cooperation and other matters, and assist the buyer in preparing the project site. The buyer shall prepare the water source, power source and steam source required for equipment commissioning and operation to connect to the seller’s equipment according to the seller’s requirements. After the equipment arrives at the user’s workshop, the goods will be unpacked in the presence of personnel from both parties. The seller’s personnel shall carry out the installation, commissioning and trial production of the equipment with the assistance of the buyer’s personnel, and achieve the design capability within the planned time. The seller is responsible for the tools and spare parts needed for installation and commissioning (except for inconvenient transportation, such as argon gas).6. Staff TrainingOur company should dispatch enough skilled technicians to put the machine into use within the necessary time and train customer personnel. The technical staff’s air tickets, board and lodging fees and any car rental costs will be borne by the buyer7.GuaranteeThe above products are guaranteed not to be affected by possible defects in materials and/or workmanship within 12 months from the date of installation. If the buyer issues a written notice in a timely manner within 15 days after the defect is discovered, and within the above-mentioned maximum period of 12 months, the seller will repair and/or replace the defective part at its own expense.8.After Sales ServiceAfter the installation and training plan is completed, if the buyer submits a written application to the seller, the seller will intervene and provide services to the machinery and/or equipment provided. Every time a service is requested, the buyer‘s technical staff‘s travel expenses (round trip), board and lodging, and any rental car expenses must be paid, as well as a daily fee of US$150 per technician.

Contact person

Cherrydou

whatsapp&wechat 861774362416

eamil: sales@shfillingmachine.com