- PRODUCT DETAIL

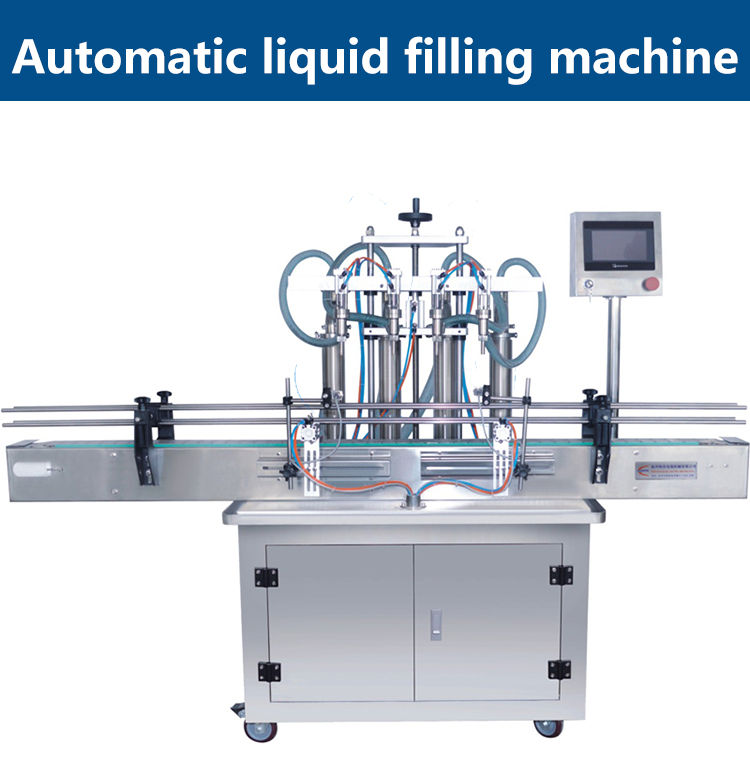

Linear Liquid Filling Machine

Efficient, Precise, and Versatile Filling Solution

The Linear Liquid Filling Machine is an advanced automatic filling system designed for accurate and high-speed filling of various liquid products. It is ideal for industries such as food and beverages, cosmetics, pharmaceuticals, chemicals, and household products.

Product Overview

This machine adopts a linear structure design, allowing for flexible adjustment of filling heads and production lines according to different bottle sizes and production requirements. It is equipped with a high-precision servo control system and intelligent PLC with a touch screen interface, ensuring stable operation, easy adjustment, and user-friendly control.

Key Features

High Precision Filling: Utilizes servo-driven piston or flowmeter systems for consistent and accurate liquid dosing.

Flexible Bottle Compatibility: Suitable for filling various shapes and sizes of bottles, including round, square, and flat bottles.

Easy Operation: The intuitive touch screen interface allows quick parameter settings, recipe storage, and fault detection.

Hygienic Design: Made of high-quality stainless steel and food-grade materials, compliant with GMP standards.

Modular Design: Number of filling nozzles can be customized (commonly 4, 6, 8, 10, or 12 heads) to meet different production capacities.

Wide Application Range: Suitable for liquid products such as mineral water, juice, shampoo, detergent, oil, lotion, and more.

Technical Advantages

Adjustable filling volume and speed

Anti-drip nozzles to ensure clean filling

Optional automatic capping and labeling integration

High production efficiency with low maintenance cost

Applications

The Linear Liquid Filling Machine is widely used in:

Food and Beverage Industry: sauces, edible oils, juices

Cosmetic Industry: shampoo, lotion, cream

Pharmaceutical Industry: syrups, disinfectants

Chemical Industry: detergents, lubricants, solvents

Why Choose Us

With years of experience in filling technology, we provide customized filling solutions to match different product characteristics and container types. Our machines are built for stability, precision, and long-term reliability, helping our customers achieve efficient automated production and improved product consistency.

Would you like me to make this version sound more promotional/marketing-style (for a homepage), or more technical and specification-focused (for a product details page)? I can tailor it accordingly.