Small liquid filling machine is cheap price, good quality, and widely used. If you use it for canned bottle juice, it can be used as a small juice filling machine and a small scale bottle filling machine. So how does the small liquid filing machine use?

Method of use small liquid filing machine

1. The ground wire must be well grounded before the machine works, and then the appropriate standard syringe should be selected according to the different loading quantity. Generally, 1ml syringe is used when the packing range is 0.2-1ml. When 1 to 5ml, a 5ml syringe is used; Use a 10ml syringe for 5-10ml; 20ml model, using 20ml glass enema; 100ml model, using 100ml glass enema, (can also use the factory’s special stainless steel filling system); The 500ml model uses our special stainless steel filling system.

2. Remove the inner core of the syringe, put the screw sleeve on the inner core of the syringe

3. Put the upper clamp seat on the water outlet of the syringe jacket, and properly tighten the nuts on both sides (when using a 5ml syringe, put the bushing together and tighten it, pay attention to the tight screw, the outer bushing is fragile).

4. Assemble the inner core and coat of the loaded syringe into one, and the liquid injection system is assembled.

5. Fix the valve arrow with the arrow mark facing outward on the fixing screw with the nut.

6. Assemble the complete liquid injection system, align the upper and lower round holes of the liquid injection system components with the upper and lower fixed rods respectively, and put them on the bearing, and make the outer end face and bearing surface level. When assembling the lower end, do not make the screw sleeve and the crank collide to avoid abnormal sound when the upper crank rotates (the distance between the screw sleeve and the crank is about 1mm when correctly installed). After the liquid injection system is correctly installed, tighten the upper and lower setting screws. Connect the syringe to the valve connector with a short rubber hose. The liquid inlet pipe is connected to the water inlet, and the liquid outlet pipe is connected to the water outlet. In order to prevent the liquid inlet and outlet pipe from winding, the liquid inlet and outlet pipe is stuck into the side lug mouth of the casing.

7. The crank should be able to rotate freely by hand, otherwise the assembly is wrong, and the liquid injection system should be checked whether it is fastened on the rotating bearing.

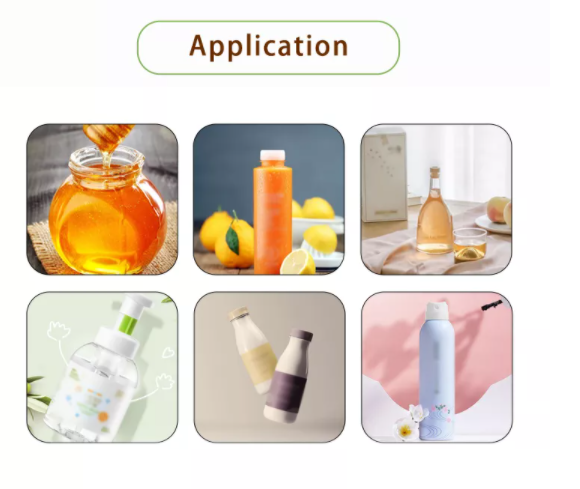

Small Juice Filling Machine Application

Small liquid filling machine video

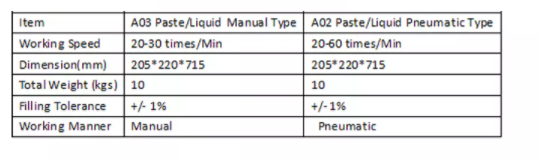

Parameters about Small Juice Filling Machine

Our company

Shean is a professional manufacturer of various filling machines.Rooted in filling machine industry for more than 20 years. We have full production experience, advanced technology and constantly updated products. Enjoy a high reputation among users.

Our company meets the needs of customers with technical innovation and attention to the reliability of overall performance. Shean’s main products are varies of filling and packing machines.

For the highest goal we are pursuing, we provide customers with turnkey projects such as design, manufacture, installation and commissioning, after-sales service and technical training for engineering projects.

We share the latest technology with you and provide the service, your trust is our aim.

Small Juice Filling Machine Packing & Shipping

The inside of the package is wrapped with plastic film, and the outside uses an export wooden box. The wooden box meets the export standards, and the fumigated wooden box is anti-insect and moisture-proof, which can also reduce customs difficulties.

Our Customer Reviews

Shean company focuses on machine sales and service for 10+ years. We not only provide customers with complete machine solutions, but also focus on helping to solve installation and debugging problems! Customer satisfaction is our pursuit.