Our new Small packing machine unit is designed for the packaging of large bags of granular materials in the chemical, fertilizer, feed, grain, seed, food and other industries. The unit has the functions of automatic weighing, automatic bag loading, automatic filling, automatic bag feeding, automatic sealing, etc

The Small packing machine is specially designed for the quantitative packaging of feed, fertilizer, soybean, corn, chemical raw materials and other materials with poor fluidity and easy caking. The belt feeding is adopted. The materials are transported to the bag through the belt. The small pouch packing machine amount is controlled by controlling the rotation speed of the belt. Once the bag is weighed and filled, its bag gripper is opened through the control system. After the bag falls, it is transported to the bag sewing station through the conveyor belt. The bag is manually assisted to seal the bag seam (sealing method: 1, directly seal the bag seam 2, add sealing paper strip seam 3 to the bag mouth, and fold the edge to seal the bag seam) according to the customer’s production needs.

When the Small packing machine enters the automatic operation state, the Small packing machine

weighing control system opens the feeding door to start feeding. The feeding device adopts the fast and slow two-stage feeding mode; When the material weight reaches the set value of fast feeding, stop fast feeding and keep slow feeding; When the material weight reaches the final set value, close the feeding door to complete the dynamic weighing process; At this time, the system detects whether the bag clamping device is in the predetermined state. When the packaging bag has been clamped, the system sends a control signal to open the discharge door of the weighing hopper, and the materials enter the packaging bag. After the materials are discharged, the discharge door of the weighing hopper is automatically closed; After unloading the materials, release the bag clamping device, and the packaging bag will fall down automatically; After the bag falls, it is sewn and transported to the next station. It operates automatically in such a cycle,small packing machine price is cost-effective

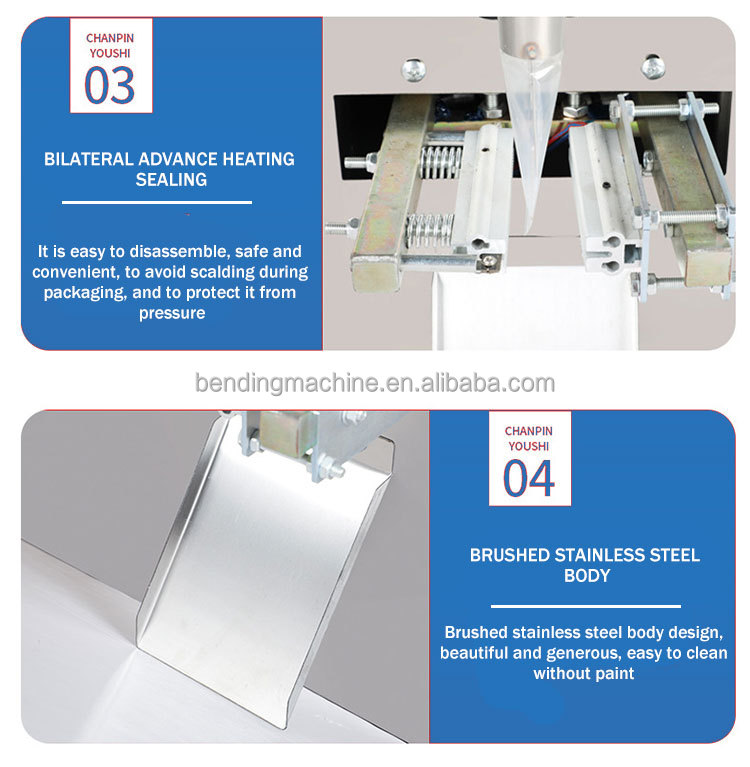

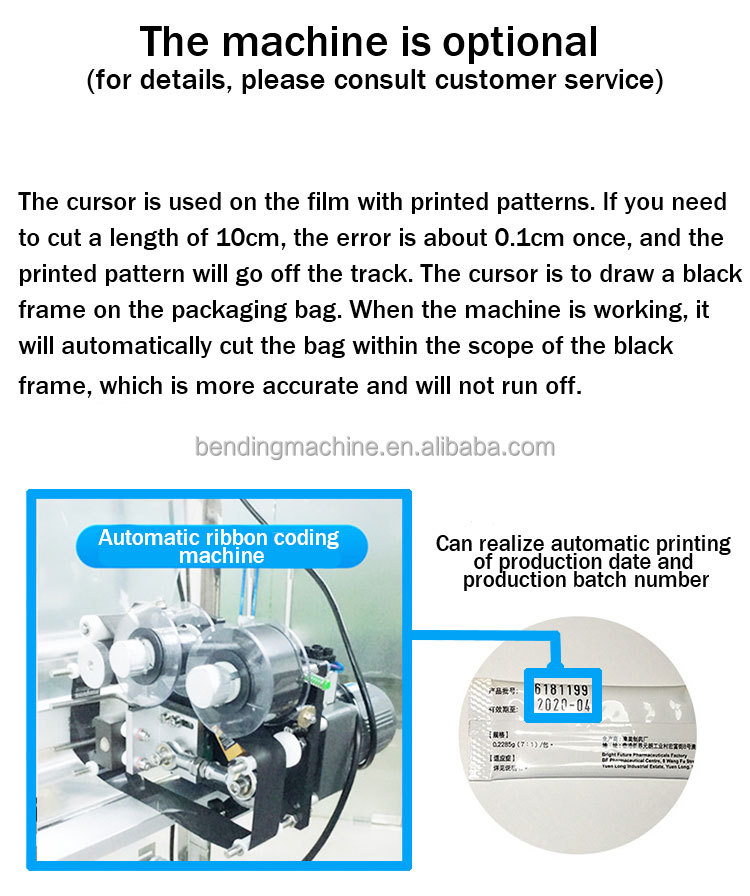

Pictures of the machine and detail parts

Advantages of the Small packing machine

★ Small size, light weight, oblique throwing and feeding, no material damage due to extrusion, especially suitable for the subpackage of fragile materials

★ The small packing adopts slope blanking, and the equipment packaging is accurate and fast.

★ High precision, it can be used for subpackage of small amount of materials, and no debris will be produced during subpackage

★ Intelligent speed regulation requires no adjustment of automatic transmission, and has higher efficiency.

★ Our company can also carry out non-standard customization according to the needs of users, and users are welcome to order.

★ The small packing machine adopts microcomputer self control, which makes the subpackaging more accurate, fast and fully automatic.

features:

Application Picture

Small packing machine can suitable for food, medicine, chemical industry and other particles, powder, liquid, paste, paste, etc. Such as milk powder, soybean powder, seasoning powder, granules, materials, granulated sugar, seed powder soup, desiccant, sauce, oil bag, honey, shampoo, cosmetics, coffee, MSG, salt, etc

Description about Small packing machine

| voltage | 220v 50hz |

| power | 200w |

| packing speed | 25-35packages/min |

| dimensions | 72*59*113cm |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We focus on the production of various types of packaging machines, powder, granules, bread, cakes, chocolate, candy, hardware accessories, daily necessities, our machines have perfect after-sales service guarantee and high-quality quality assurance, the machines are all imported PLC The controller, the machine performance is very perfect and very intelligent, which greatly saves manpower for the user, and we also provide customized services, which can be customized according to the needs of users

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

This is one of my Saudi Arabian customers who used our machine, greeted me every day and told me that the machine is working very well every day, the machine is really easy to use, and it saves them a lot of manpower