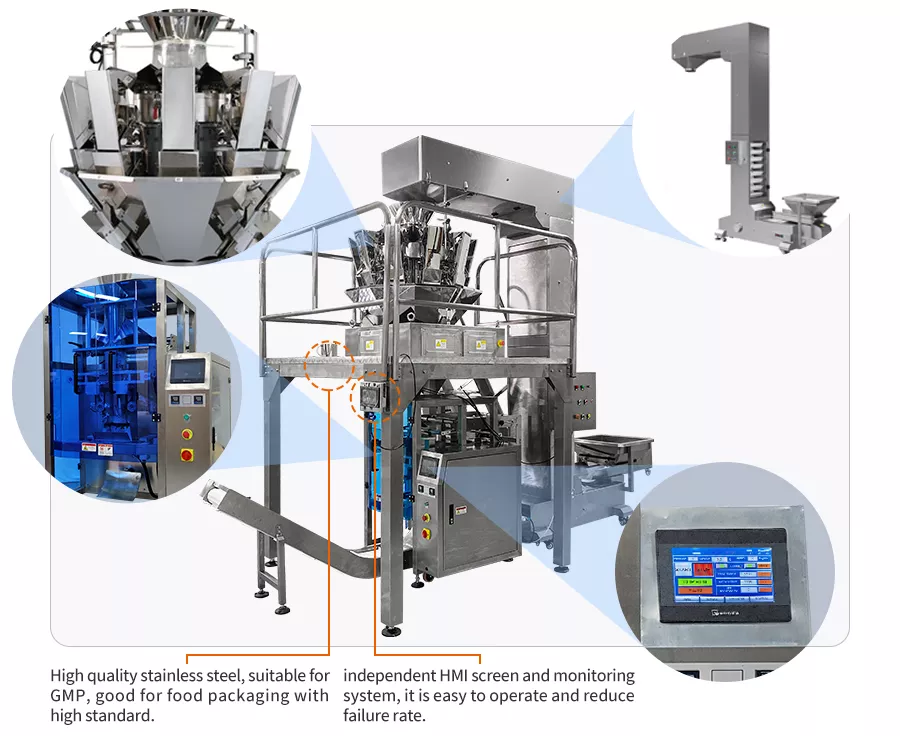

snacks packing machine is composed of Z-type material hoist, lateral film feeding vertical packaging machine, micro combination scale, intelligent thermal transfer coding machine, finished bag conveyor, equipped with ARM intelligent control system, rejecting device, continuous bag packaging, suction This set of equipment is maintenance-free, has good performance, low cost of use, easy operation, high precision, and fast speed. It can automatically complete the functions of feeding, weighing, filling, film pulling, bag making, exhaust (flushing), printing, counting, dust removal, bag making, automatic rejection of overweight and out of tolerance unqualified products, and no material without packaging. Finish.

snacks packing machine is made of 304 stainless steel, all welding places are smooth and flat, the parts in contact with the material are polished, and the outer surface of the equipment is also polished, which is in line with GMP certification standards.The snacks packing machine can be continuously produced for 24 hours, and each process runs stably, and has the characteristics of strong application, reliability, durability, economy, energy saving, advanced, easy operation, easy disassembly, and easy clearance;

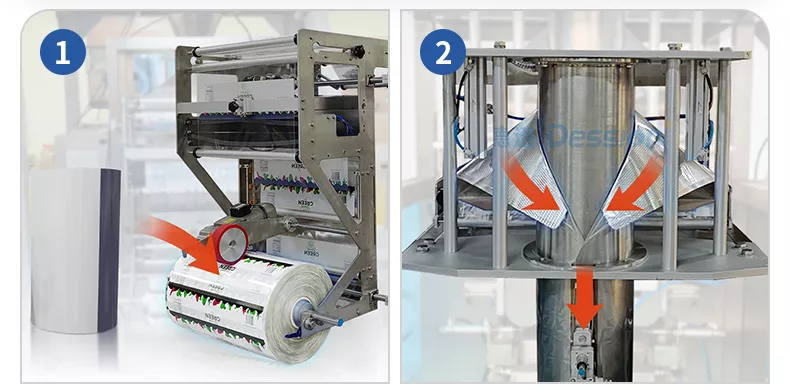

snack packaging machine can automatically complete feeding – sieving powder, suction iron filings – lifting and feeding – automatic weighing – packaging material coding – packaging – discharging – finished product delivery. Unqualified finished products before packaging can be automatically rejected;

banana chips packing machine with an automatic feeding hoist, which can screen powder, absorb iron filings, realize automatic feeding, and is easy to clean, without hygienic dead corners; Weighing by a micro combination scale, the weighing hopper is mirror polished, the number of weighing hoppers is not less than 10, the loading hopper is safe, easy to clean, mirror polished, supports 100 sets of production data parameter storage, easy to quickly exchange production data;

Advantages of snacks packing machine

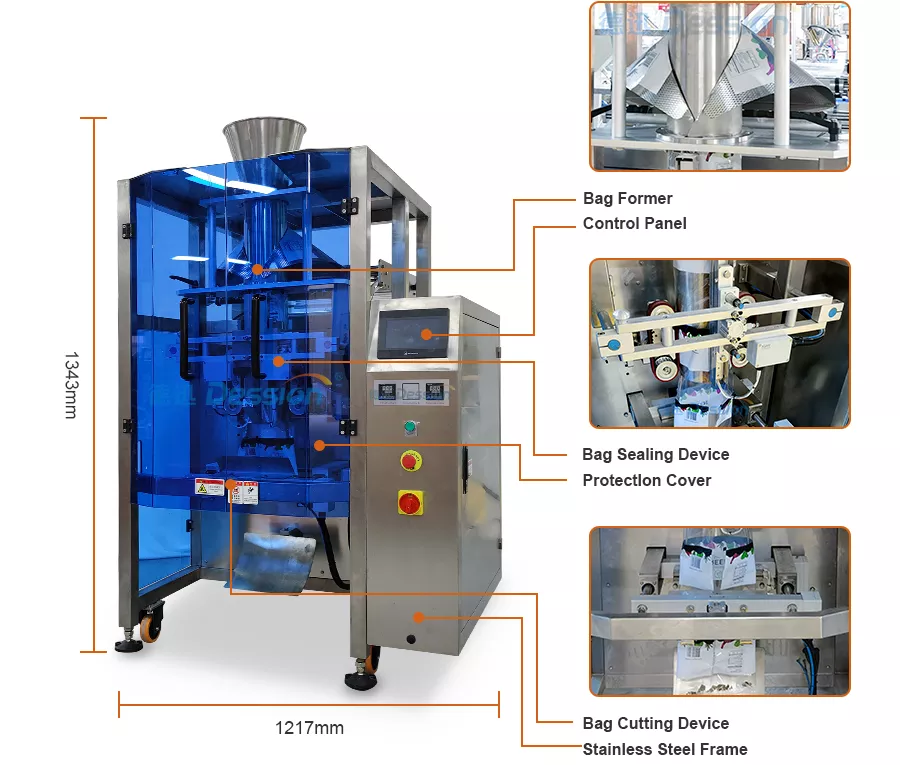

1. The new appearance patent makes the model more luxurious and high-end;

2. The sturdy and beautiful protective door has good waterproof and protective functions;

3. More than 90% of the parts are made of high-quality stainless steel, which makes the machine life longer;

4. The electrical components are imported brands, which are of real high quality and packaged for the stable operation of the machine;

5. It adopts separate membrane loading system, which is convenient and practical;

6. The coding machine is installed upside down, which is easier to adjust and replace;

7. The newly upgraded and improved former makes the packaging bag more high-end and beautiful.

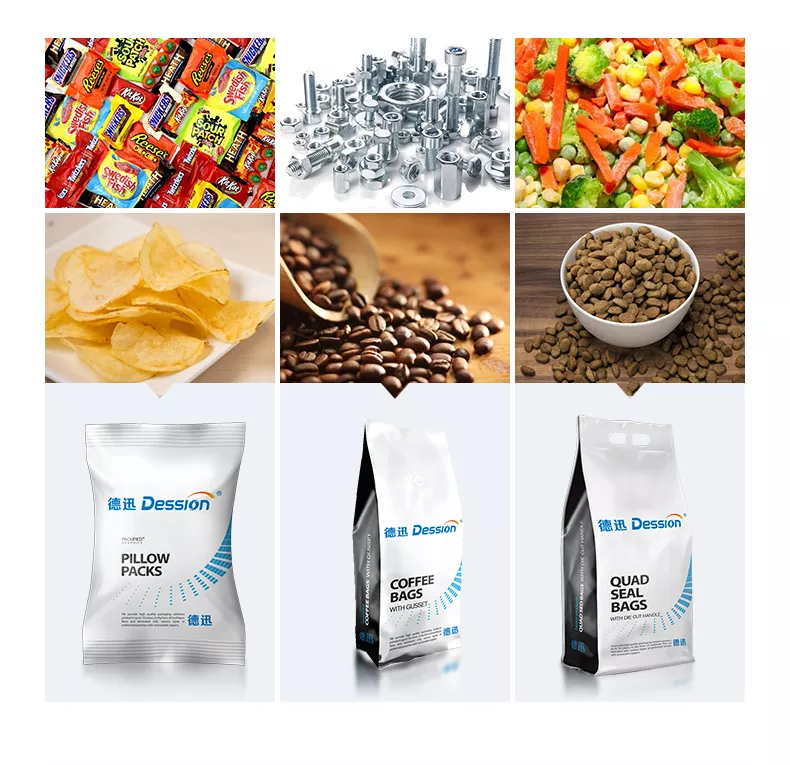

Application of the snacks packing machine

snacks packing machine is suitable for packaging of bulk objects requiring high measurement accuracy and fragile, such as: puffed food, potato chips, fried rice, jelly, candy, pistachios, peanuts, beans, apple slices, dumplings, rice balls, medicinal materials,etc.

Description about the the snacks packing machine

| Packing speed: | 45b/m |

| Bag width | Front width: 70-200mm Ironing width: 5-7mm Side width: 30-100mm |

| Bag length: | 100-350mm |

| Bag making form: | Pillow bag, prong bag, ironing bag |

| Roll film range: | 220-520mm |

| Roll film thickness: | 0.04-0.09mm |

| Packaging film material: | BOPP/CPP,BOPP/VMCPP,BOPP/PE,PET/VMPET/PE,PET/PE等 |

| Air consumption: | 0.8Mpa 0.35m³/min |

| Power Type: | 4.3KW 220V 50HZ/60HZ |

| Dimensions: | 1300x 2050x1910mm |

| Total Weight: | 750kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing all kind of goods or liquid or paste packing machine. The beverage, paste, beer, oil, milk, Bird’s nest illing-packing equipments ,water treatment equipments is blong us our production area.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality

snack packaging machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our Customer Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.