When Tea bag packing machine , the packing process of the vertical packaging machine, the material is fed by the material stretching and feeding device. The plastic film is formed into a cylindrical shape through the film cylinder, and the side is sealed by the heat longitudinal sealing device. The standard photoelectric detection device cuts the length and position of the packaging.

The tea bag filling and sealing machine with Exactly correct weight in a sealed environment , the dsame density , the method of measuring the volume to caluculate the accurate weight , during time for move and mix , the closed space make the goods uniformely ad with actully CBM measure .Due to the different in density , the pressure and completeness of htevertidal fall process determine that the electronic scales is not accurate every time

Tea packing machine price with regular motor with pole . only one ordinary geered motor connecting rod adjsut speed and size. servo motor with the longitudinal seam is driven by a variable frequency motor and the packaging speed is steplessly adjust . the horizontal sealing uses a servo motor to dirve the length of the packaging bag

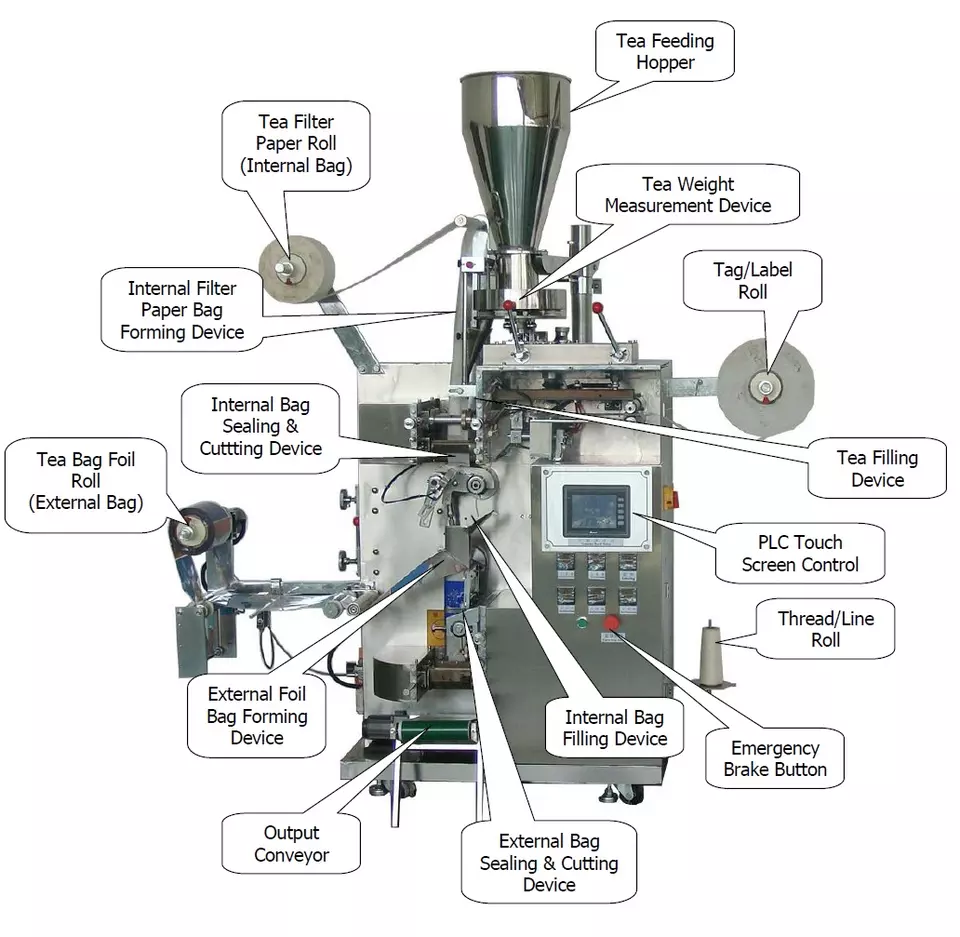

Tea bag filling and sealing machine withThe inner and outer bag are formed at one time, which avoids direct contact between human hands and materials , and is clean and hygienic to improve efficiency

The inner bag ismade of filter cotton paper ,which can be automatic cally brought with thread and label , and the outer bag is made of composite materia.

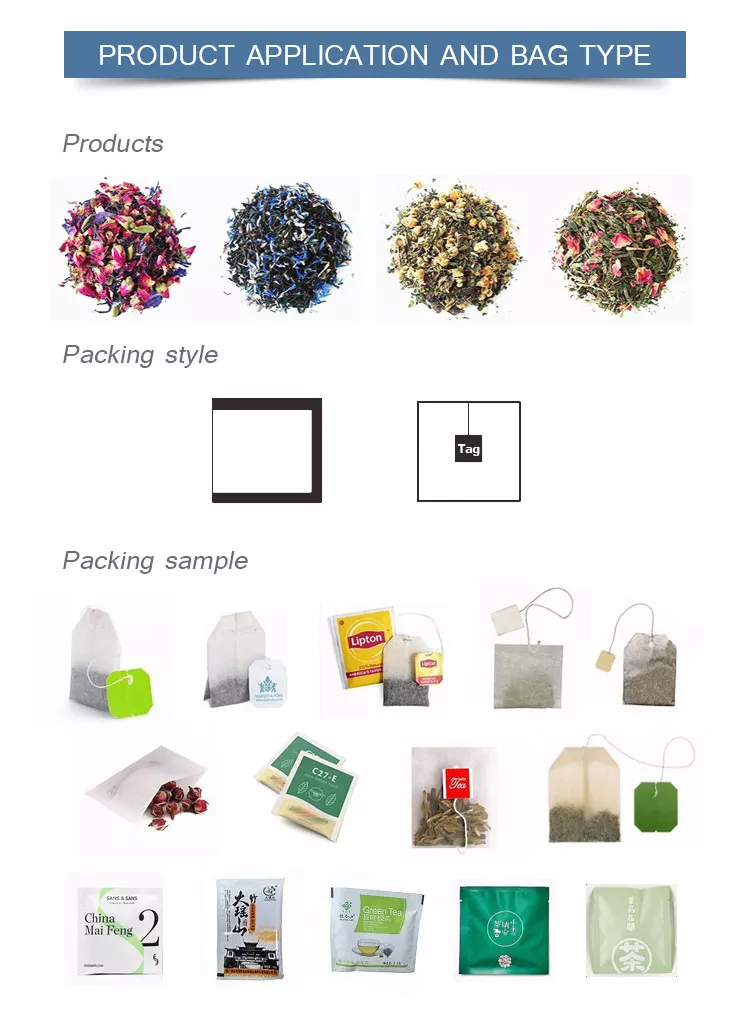

Tea bag packing machine can choose the packaging form with line and label. According to the packaging capacity , inner bag,outer bag .label ,etc, all can be adjusted aribitranily,and size of the inner and outer bags can be adjusted according to the diferently needs of users to achieve the most ideal packaging effect.

Improve the appearance of the product and increase the value of the product.

Precise turntable metering and blanking method.Accurate metering can greatly improve the production efficiently of the equipment.

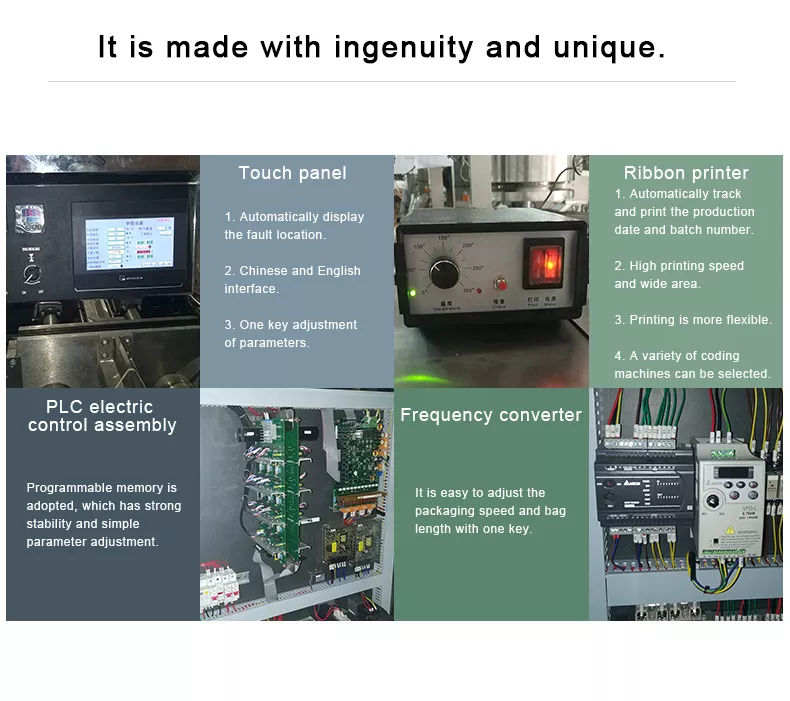

Tea bag packing machine with Touch man machine panel, sinemens PLC controller, adopt servo electric mechanism bag, can adjust multiple parameters according to demand, provide users with maximum operating flexibility

Advantages of Tea bag packing machine

1.Envelope is controlled by stepping motor, accurate bags size and positioning accurately. 2.PID adjust temperature controller. 3.The whole machine is controlled by PLC, touch screen, very easy to operate. 4.All parts contact with materials adopt SS304, up to GMP standard. 5.Some of cylinders adopt imported brand, which can ensure working accurate and stable. 6.Can equip with printers, flat cutter or easy-opening etc.

7.Bag size can be changed by different formers.

Application of Tea bag packing machine

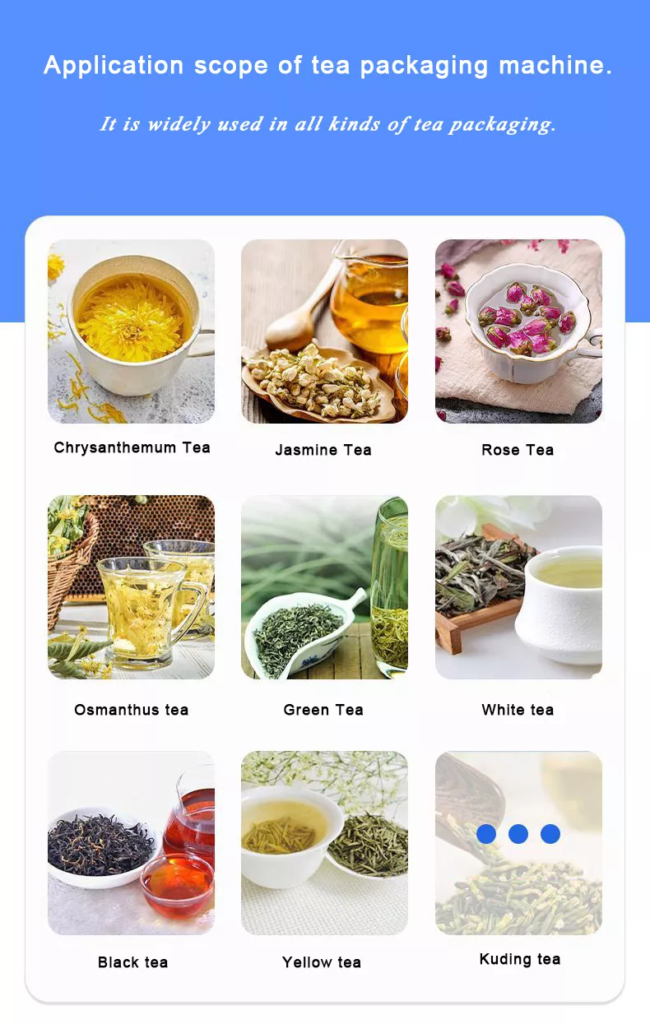

Tea bag packing machine is suitable for packaing granular material such as green tea, black tea, black tea, oolong tea, huanggong, white tea, scented tea, healthy tea, tartary buckwheat , chinese herbal tea, coffee, wolfberry etc

Tea bag packing machine of video

Description about the Tea bag packing machine

| Model | Multi-Function Packaging Machine |

| Sealing Type: | Three Size Sealing |

| Filling Range | 1~5g/bag |

| Size of outer bag: | L85-120mm; W75-95mm |

| Power | 220v/50hz/60hz, single phase |

| Core components | Motor and plc |

| Size of inner bag | L50-75mm; W50-75mm |

| Size of tag | 20x20mm |

| Total Power | 3.7kw |

| Pacing Speed | 30~50bags/min |

| Packaging Type | Stand-up Pouch, Bags |

| Function | FILLING, Wrapping, Labeling, Sealing, BOXING |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing all kind of goods or liquid or paste packing machine. The beverage, paste, beer, oil, milk, Bird’s nest illing-packing equipments ,water treatment equipments is blong us our production area.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Tea bag packing machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our Customer Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.