Tin can sealer is a machine commonly used in daily production and life.The tin can sealer can work alone or cooperate with the conveyor line for assembly line production. The aluminum can sealer machine not only improves the production capacity and filling efficiency, but also expands the scope of application, from manual can sealer machine to semi-automatic, from semi-automatic production to fully automatic production, and efficiently completes the filling and sealing of various beverages. Tin can sealer is a new generation product that replaces manual operation and manual semi-automatic production in today’s beverage equipment industry. It is an ideal equipment for large-scale beverage factories and food industries.

The small seaming machine has the advantages of surpassing the semi-automatic small seaming machine and manual operation, computer control, and high production efficiency. The whole machine is made of 304 stainless steel, the small seaming machine is controlled by microcomputer, without manual intervention, which improves the production efficiency. Automatic filling, automatic sealing, reasonable results, advanced quantitative filling technology and stable sealing technology, the operation Reliable, low operating cost; the general service life can be increased by more than 5 years.

The small seaming machine integrates filling, sealing, coding and packaging. The whole process is automatic cup dropping, automatic quantitative filling, automatic sealing, automatic coding and assembly of equipment. Rigid container refers to the container whose shape is not easy to change after the container is formed. It is usually sealed with different types of lids by small seaming machines. The commonly used sealing machines are as follows. Screw cap sealing machine. This kind of cover has internal threads processed in advance, and the threads can be single-ended or multi-ended.

Its external material is made of stainless steel and aluminum alloy, which meets hygienic requirements and is especially suitable for small and medium-sized enterprises.

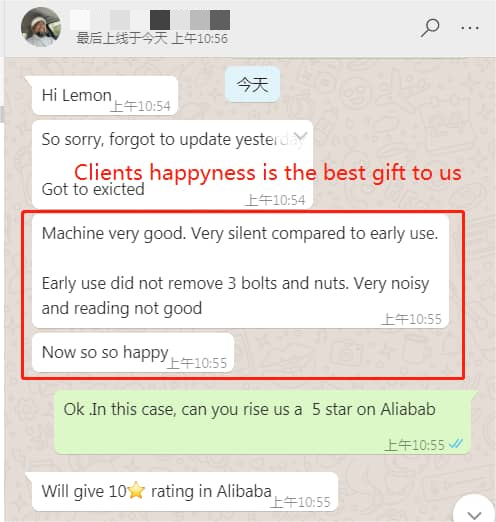

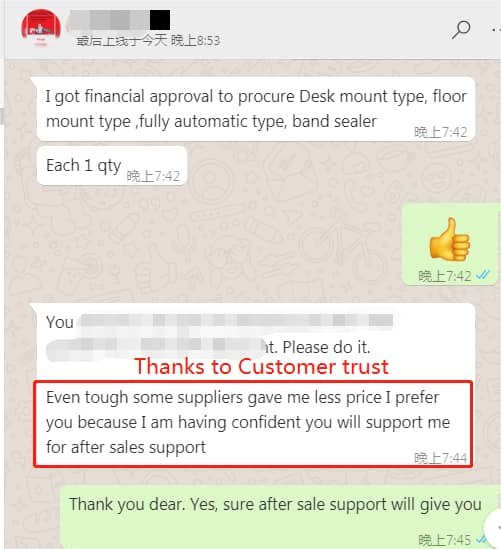

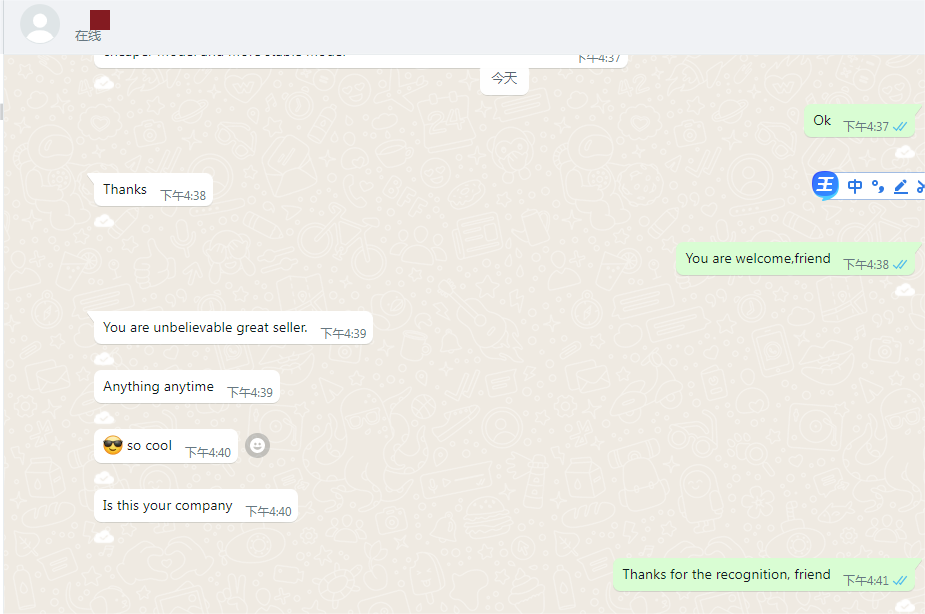

In addition to the good quality of the machines, the reason why our machines are popular is our after-sales service is professional and timely.

We will give some replaceable wearing parts in the goods after the customer buys the machine. We provide customers with one-year machine warranty and 7*24 hours of online after-sales service. When there is any problems after the machine reaches the customer, we will help solve it according to the customer in time.

Tin can sealer Application

Tin can sealer video

ParametersaboutTin can sealer

| Model | LT-160 |

| Canned seal number | 1 |

| Sealing speed | 10-20pcs/min |

| Sealing height | 40-200mm adjustable |

| Suitable diameter range of bottle | 35-126mm adjustable |

| Packaging size | 730*600*380mm |

| Weight | 50kg |

Our company

Shean is a professional manufacturer of various powder filling machines.Rooted in filling machine industry for more than 20 years. We have full production experience, advanced technology and constantly updated products. Enjoy a high reputation among users.

Our company meets the needs of customers with technical innovation and attention to the reliability of overall performance. Shean’s main products are varies of filling and packing machines.

For the highest goal we are pursuing, we provide customers with turnkey projects such as design, manufacture, installation and commissioning, after-sales service and technical training for engineering projects.

We share the latest technology with you and provide the service, your trust is our aim.

Automatic cup sealing machine Packing & Shipping

The inside of the package is wrapped with plastic film, and the outside uses an export wooden box. The wooden box meets the export standards, and the fumigated wooden box is anti-insect and moisture-proof, which can also reduce customs difficulties.

Our Customer Reviews