We are offering all kinds of filling machines,like desktop filling machine,horizontal filling machine,linear filling machine and servo filling machine. The best one among them is the servo

automatic bottle filling machine and normally the servo bottle filling machine price is the highest.Here,let me introduce some advantages of the servo motor.I will show you what makes it stand out.

Firstly,the filling machine can realize closed-loop control of position, speed and torque,and overcome the problem of stepper motor out-of-step.This bring it high precision compared with others.it has good high-speed performance, generally rated speed can reach 2000 ~ 3000 rpm.

Secondly,the automatic bottle filling machine has strong anti-overload capability, can withstand three times the rated torque load, especially suitable for occasions with instantaneous load fluctuations and fast start-up requirements.

Thirdly,the low-speed operation is stable, and the stepping operation phenomenon similar to that of a stepping motor will not occur during low-speed operation.This liquid bottle filling machine is suitable for occasions with high-speed response requirements.

Fourthly,the dynamic response time of motor acceleration and deceleration is short, generally within tens of milliseconds.Heat and noise are significantly reduced in the servo automatic bottle filling machine.

But the cost of the servo filling machine is very expensive.I think that’s the only disadvantage of the machine.

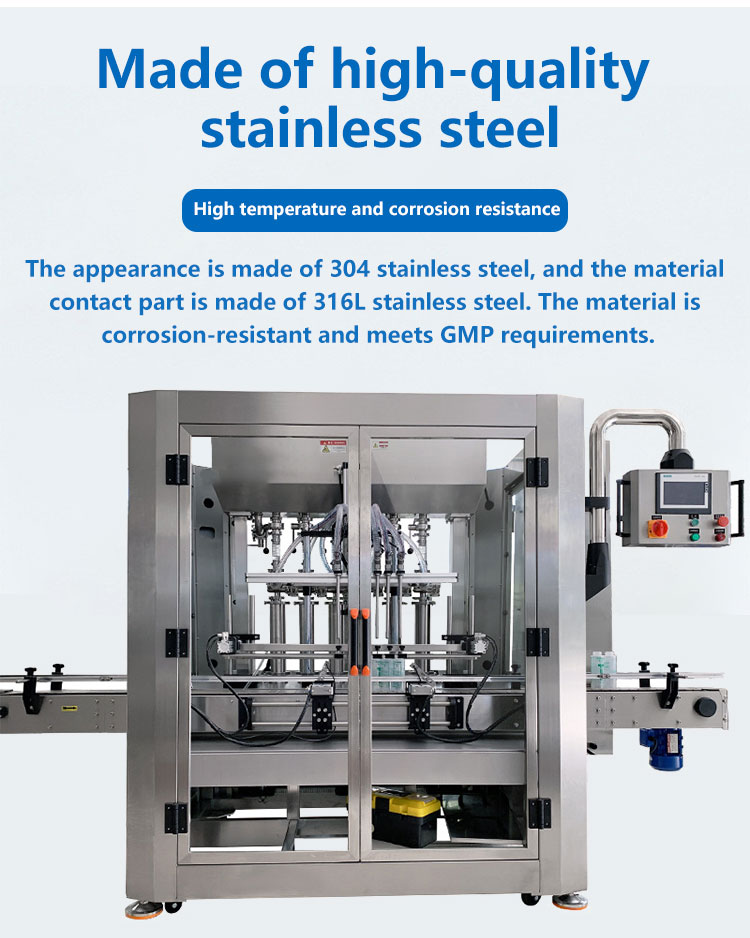

Pictures of the machine and detail parts

Advantages of the Automatic Bottle Filling Machine

1.The machine uses high-quality components at home and abroad. The quality assurance make you more comfortable to use.

2.The filling machine has adopt Japanese Keyence fiber optic electric eye automatic shutdown function,so no bottle no filling.The machine’s automatic shutdown function can use for accumulated bottles.It’s sensitive about response and very durable.

3.The appearance is made of 304 stainless steel,and the material contact part is made of 316L stainless steel.The material is corrosion-resistant and meets GMP requirements.

Automatic Bottle filling Machine features:

Application Picture

Automatic Bottle filling Machine video

Description about Automatic Bottle Filling Machine

| Item | Description |

| Power | 1-10kw |

| Power supply | 220V/380V |

| Air pressure | 0.5-0.7Mpa |

| Speed | 0-100 bottles/min |

| Accuracy | ±1% |

| Model | 50-500ml/100-1000ml/500-3000ml/1000-5000ml |

| Number of filling heads | 2、4、6、8(design for customers) |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

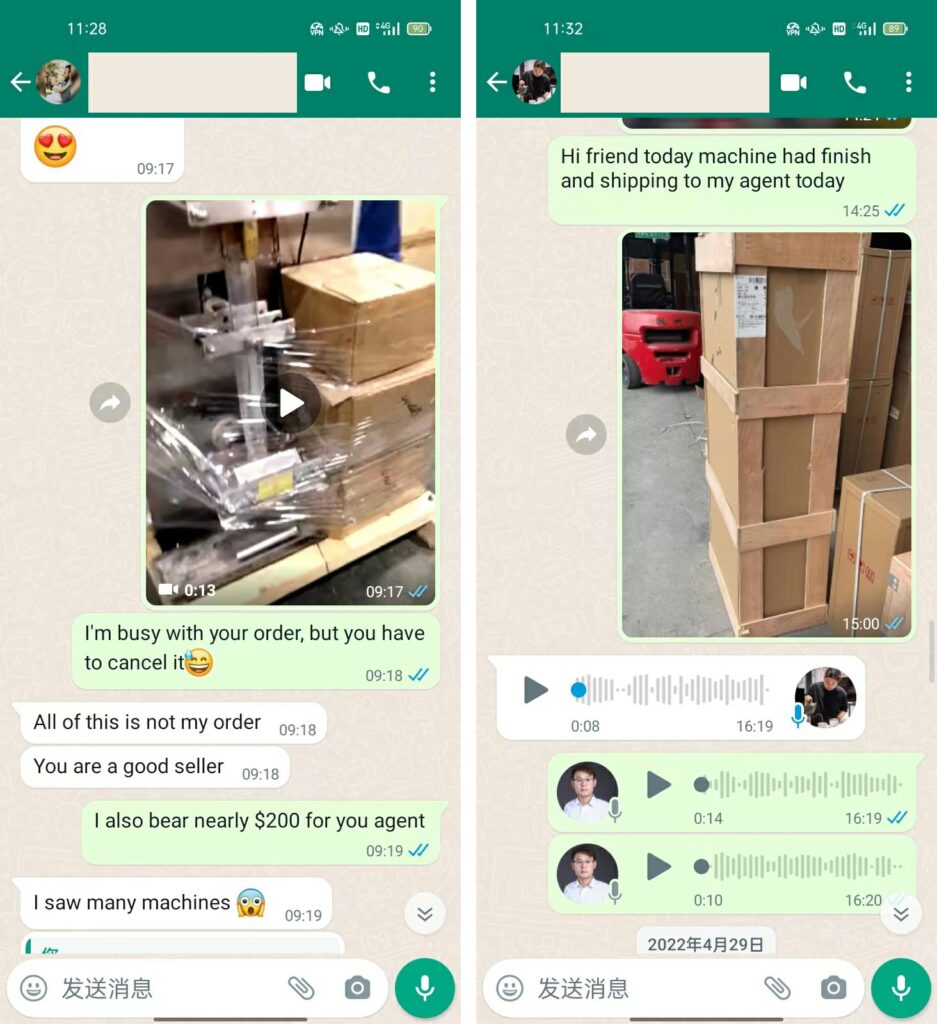

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our customers’ Reviews

These how we help all of customers to check how the machines produced and packed.

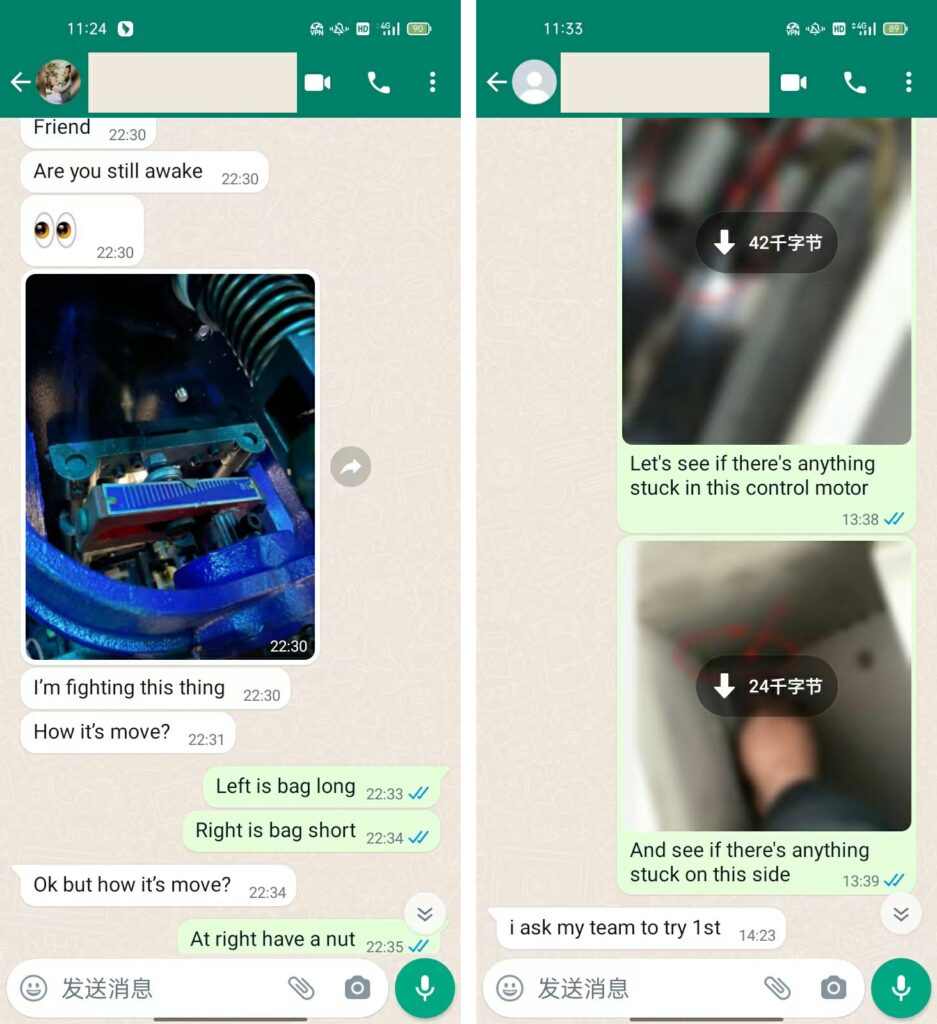

These how our customers satisfied with our machines.

We are very focus on the after-sales services.After our customers got the machines,we would send them the manual in customers’ languages,the videos about how to adjust the machines and how to run them.So even you are opening a new industry or business,don’t know much about the machines.You can definitely trust us,we will help you with any technical issue.

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.