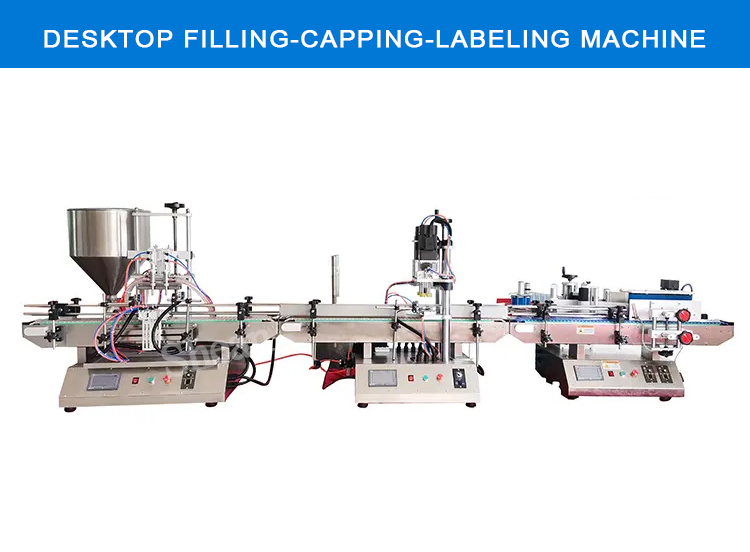

Pictures of the machine and detail parts

The machine typically consists of several components:

1. Filling System: This system includes a liquid reservoir or tank, a pump or valve mechanism, and a nozzle or filling head. It accurately dispenses the liquid into the bottles with the desired volume.

2. Capping System: The capping system consists of a cap feeder, a cap sorting mechanism, and a capping head. It securely seals the bottles with caps, ensuring a tight and leak-proof closure.

3. Labeling System: This system consists of a label dispenser, a labeling head, and a conveyor. It applies pre-printed labels onto the bottles, ensuring accurate and consistent placement.

The desktop liquid bottle filling, capping, and labeling machine offers several advantages, including:

1. Compact Size: Its small footprint makes it suitable for limited workspace or small-scale production environments.

2. Automation: The machine automates the entire process, reducing manual labor and improving production efficiency.

3. Accuracy: The machine ensures precise and consistent filling, capping, and labeling, minimizing product wastage and ensuring product quality.

4. Versatility: It can handle a wide range of bottle sizes and shapes, making it suitable for various liquid products.

Application Picture

It is suitable for automatic filling of liquids of different viscosity in food, chemical, daily chemical, liquor, edible oil and other industries. Linear filling machine is mainly used for liquid filling, such as lotion, care liquid, oral liquid, skin care liquid, base liquid, antifreeze, shampoo, hair care liquid, hand soap, lotion, nutrient solution, detergent, shower gel, Perfume, milk, juice and other beverages. Lubricants and other industries.

Description about Desktop filling capping and labeling machine

| Machine name | Desktop Filling-Capping-Labeling Machine |

| Filling head | 2 nozzles/4 nozzles |

| Filling materials | Paste ,Thick liquid, Liquid |

| Accuracy | ±1% |

| Speed | 400-1800 BPH (according to the size of the bottle ) |

| Max filling range | 1000ml( 30 ml-1000ml) |

| Bottle size | Diameter:30~100mm; Height:60~200mm |

| Air pressure | 0.6~0.8Mpa |

| Machine size and weight | Machine size:1200*900*680mm,70kgPacking size:1250*950*780mm; 90Kg |

| Power | AC 220V ; 50/60HZ ;120W |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Desktop filling capping and labeling machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.