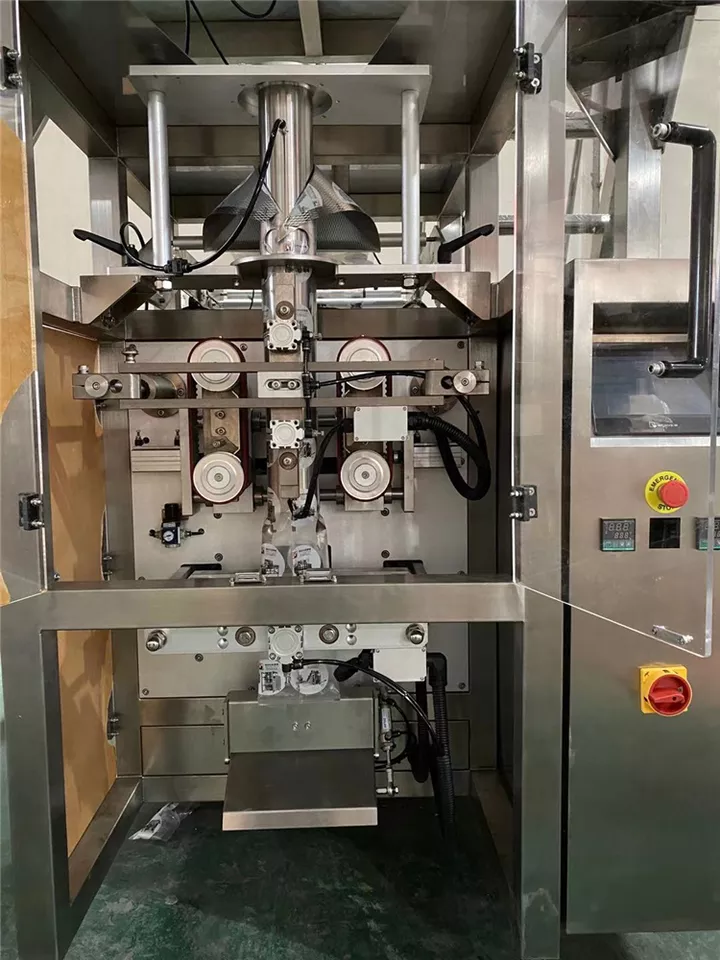

The food packaging machine is suitable for loose rounded granules in the food, chemical and other industrial. Such as: puffed granules, peanuts, popcorn,melon seeds, rice, pepper, sugar,salt,Food packaging machine consist with feeding converyor ,. weighing system, support platform and packing.It includes Z-type bucket elevator has the advantages of flexible composition small damage to the material itself and reduction of scrap rate. Strength of standard combination weigher : wide rage of application,high price competitiveness, reliable performance.10.4 inch color display, lots of language can be chosen.Speed and amplitude can be adjusted in operation process.Weigh hopper followed by discharge, effectively prevents blockages.Amplitude of each linear feeder can be adjusted separately.99 of present programs are preprogrammed in stock.

The shell of the whole machine is sealed to reduce dust flying. Snack packaging machine of when the weighing hopper under the storage hopper is empty after discharging, the storage hopper is opened,the material is discharged to the weighing bucket, and the weighing bucket starts to weigh.it has the advantages of stable transportation, simple structure, easy maintenance and low cost. Food packing equipment has SIMENS PLC CONTROL SYSTEM and itelligent control System : All setting in 1 computer. The food packaging machine with common function button separate, convenient for users. The weighing speed you require(bag/min). The weigh of each pack you need.

food packaging machine with multihead weigher back seal packing machine for crackers chip vertical ffs packaging machine for biscuit cookies, it packing standard with Waterproof PO film+wooden caseDedust & Cleaning. Lubricate Drive Parts.Divide Machine Into Modules.Wrap Modules With Plastic Film. Packing Modules Into Plywood Cases. Mark Shipping Mark In The Cases.As per customer’s package requirement.

Advantages of the food packaging machine

1.Full-automatic Weigh-Form-Fill-Seal type, efficient and simple to use.

2 Use famous brand electric and pneumatic components, stable and long life circle.

3 Use superior mechanical components, reduce the wear out loss.

4 Easy to install film, auto correcting the excursion of the film.

5.Apply advanced operating system, easy to use and reprogrammable.

6. To be used on Jintian High quality machine, it makes your packing work easily and efficiently.

Application of the food packaging machine

Full Automatic food packaging machine is loose rounded granules in the food, chemical and other industrial. Such as: puffed granules, peanuts, popcorn,melon seeds, rice, pepper, sugar,salt, biscuits etc.

The food packaging machine of video

Description about the food packaging machine

| Model | 320 | 420 | 520 | 720 | 920 |

| Film width | 320mm | 420mm | 520mm | 720mm | 920mm |

| Bag length | 50-200 mm | 80-300mm | 80-400mm | 80-500mm | 80-650mm |

| Bag width | 50-150 mm | 50-200 mm | 70-250 mm | 60-350 mm | 200-450 mm |

| Packing grams | 50-150 ML | 50-1500ML | 50-3000ML | 50-5000ML | 100-10000ML |

| Packing speed | 35-70bpm | 35-70bpm | 35-70bpm | 35-70bpm | 35-70bpm |

| Power | 220V/380V/50/60 HZ | ||||

| Machine dimension | 970*680*1960 mm | 1200*1500*1700mm | 1500*1600*1800mm | 1600*1700*1800mm | 1600*1700*1800mm |

| Weight | 300 kg | 450 kg | 500kg | 600 kg | 600 kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Full Automatic food packaging machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

Our Customer Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.