Before so many of my customers,especially the new beginners,the most popular question they asked me is that what’s the difference between (paste)honey filling machine and liquid filling machine.Once we get an inquiry about filling machine from our customers,the first question from us is always what material do you want to fill and you would better to send me a video so i can see how thick is the material.Why is that?Why is so important that we have to divide the liquid and paste material? Why honey bottle filling machine always cost more?Today,please let me figure out this puzzle for you.

Firstly,let us clear what liquid,semifluid and paste is.Liquid,usually refers to liquid raw materials with good fluidity, such as purified water, carbonated drinks, fruit juice, soy sauce, vinegar and alcohol, etc. Semifluid’s liquidity is inferior to liquid products, usually refers to edible oil, lubricating oil, syrup, loquat, honey, etc. Paste has the worst fluidity among the three, and is generally in the form of solid-liquid coexistence. Commonly there are various sauces, seasonings, and hot pot bases.

After we knew the how to divide the products,i will explain the difference in processing.Liquid filling machine generally uses normal pressure (isobaric) filling,while (paste) honey filling machine generally uses plug-type (pressurized) filling.The atmospheric pressure filling machine is filled by the weight of the liquid under atmospheric pressure,while pressure filling machines fill at above atmospheric pressure.Because the thicker the product is, the less fluid it is, the stronger the extrusion force of the filling machine is required. If we use a liquid filling machine to fill paste, it is very likely that the material will move slowly or jam.So we should use honey filling machine to fill honey,but not water.

Therefore, as I have repeatedly said before, the more comprehensive the information given by the customer, the more suitable the machine we recommend to you, and the most practical solution.We have all kinds of filling machines,not just honey filling machine for sale,so please contact with me and tell me your request,let me help you to make a perfect plan.

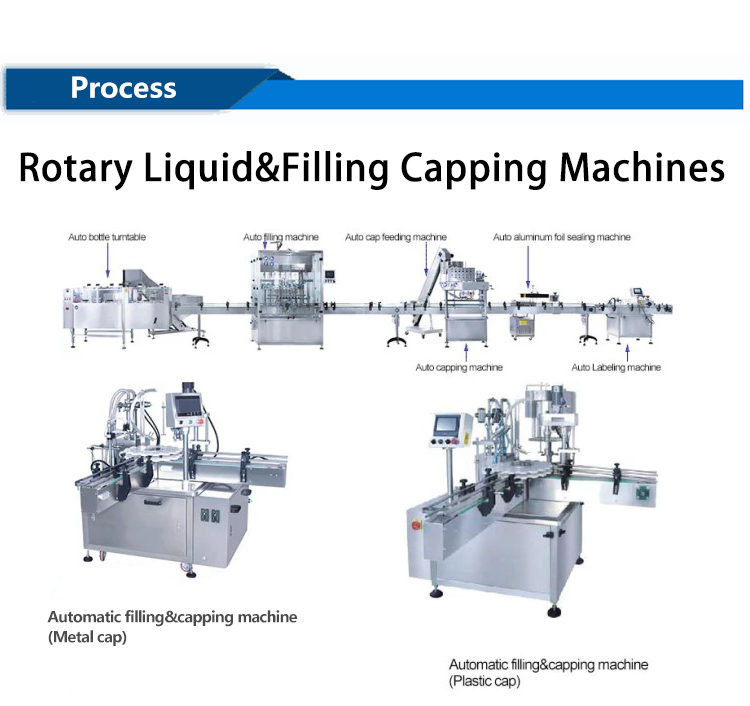

Pictures of the machine and detail parts

We normally suggest our customers to combine this process line,so it can realize the automatic production.The whole line includes auto bottle turntable machine,auto filling machine,auto cap feeding machine,auto capping machine,auto aluminum foil sealing machine and auto labeling machine.

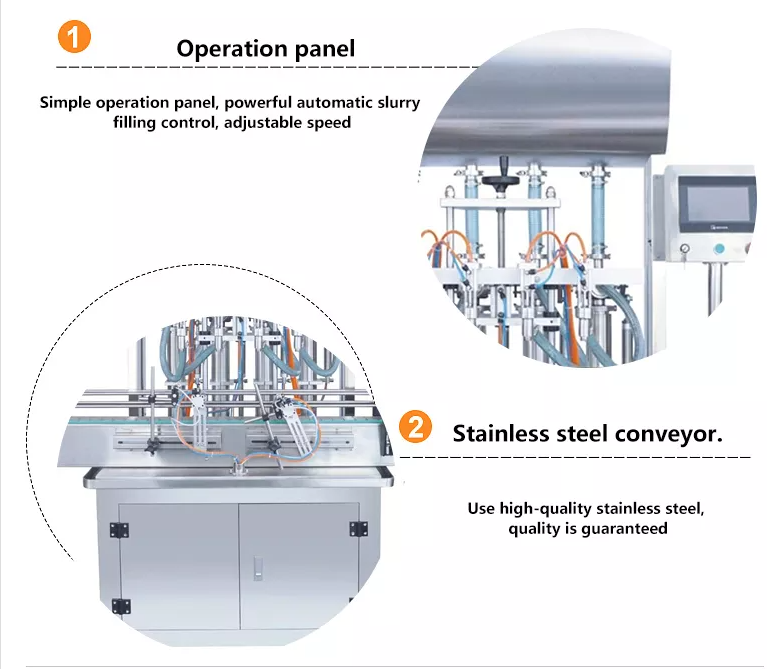

Advantages of the Honey Filling Machine

1.The filling machine equip with simple operation panel and powerful automatic slurry filling control.So it’s able to adjust the filling speed.

2.About the production of the whole machine,we use high-quality stainless steel.The machines’ quality is guaranteed.Also we have one year guaranty with out human damage.

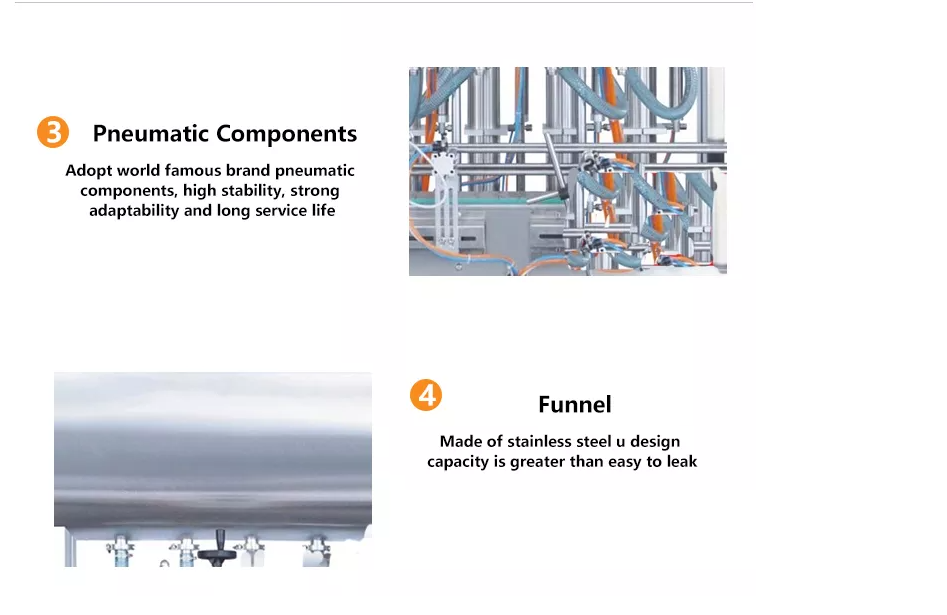

3.What’s more,all of the pneumatic components are used world famous brands which have high stability,strong adaptability and long service life.

4.About the funnel which contains the paste material,it’s made of stainless steel with U design.This design makes customers have no worries about the material will leak.

Honey Filling Machine features:

Application Picture

This paste filling machine can be used in the food and cosmetic industries,such as honey,cream,tooth paste,etc. Its field of use is very wide.

Honey Filling Machine video

Description about Honey Filling Machine

| MODEL | GT2T-2Y | GT4T-4Y | GT6T-6Y |

| Voltage | 110/220V,50HZ,800W | 110/220V,50HZ/60HZ,800W | 110/220V,50HZ/60HZ,800W |

| Filling Volume | 5-100ml,10-280ml | 20-500ml,100-1000ml | 500-2800ml,1000-5000ml |

| Filling Speed | 10-40bottles/min | 20-50bottles/min | 30-70bottles/min |

| Filling accuracy | <=±1% | <=±1% | <=±1% |

| Air Pressure | 0.5-0.7MPA | 0.5-0.7MPA | 0.5-0.7MPA |

| Weight | 220kg | 260kg | 300kg |

| Size | 210*86*146cm | 260*86*146cm | 320*86*146cm |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

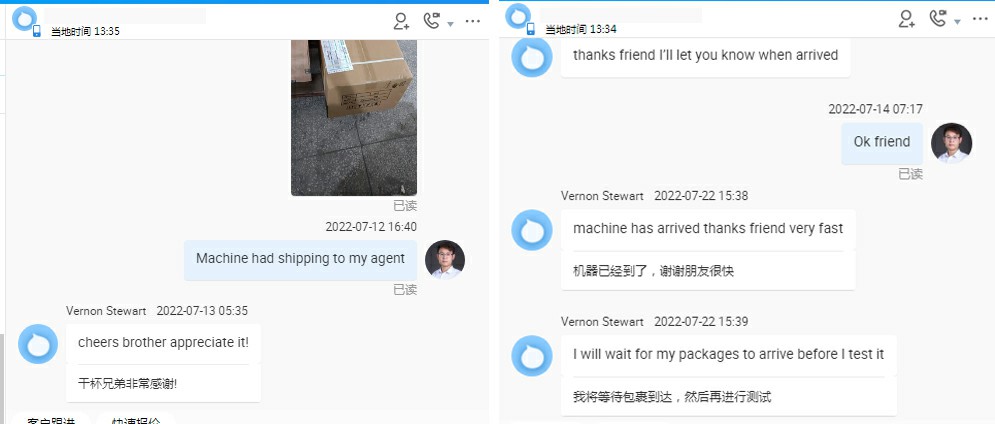

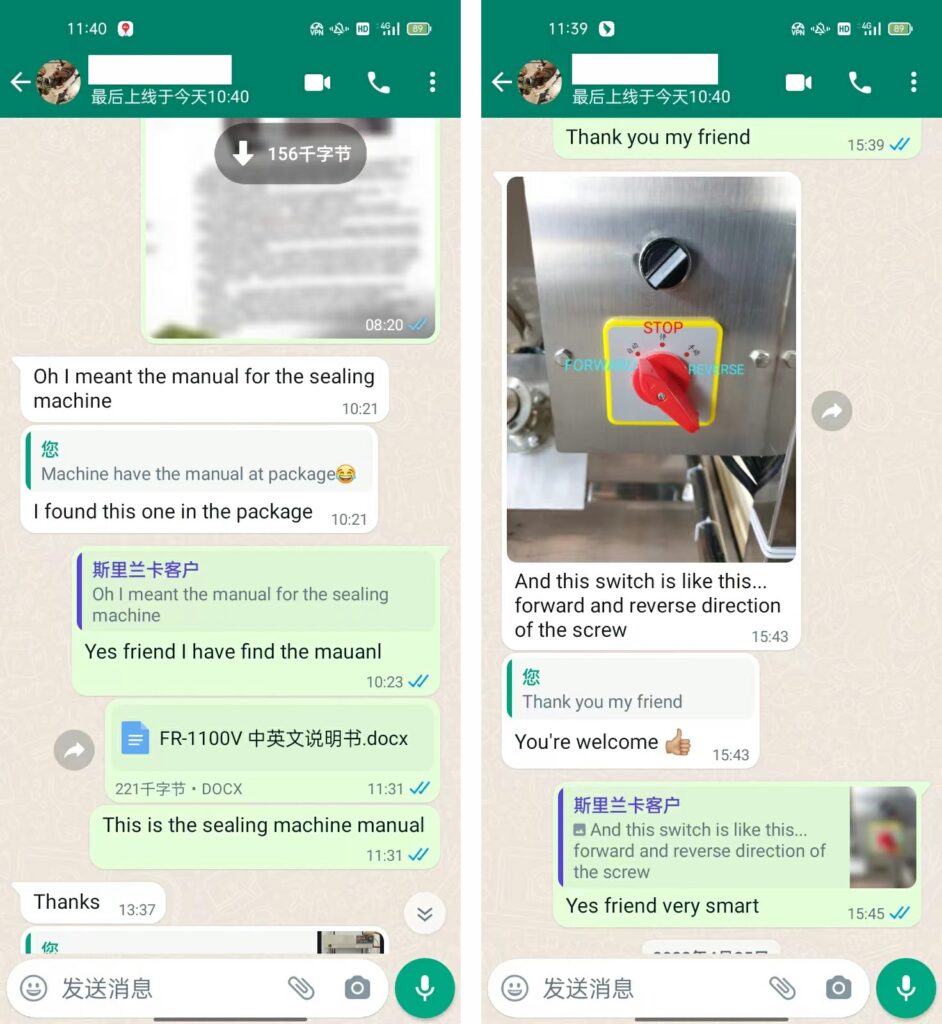

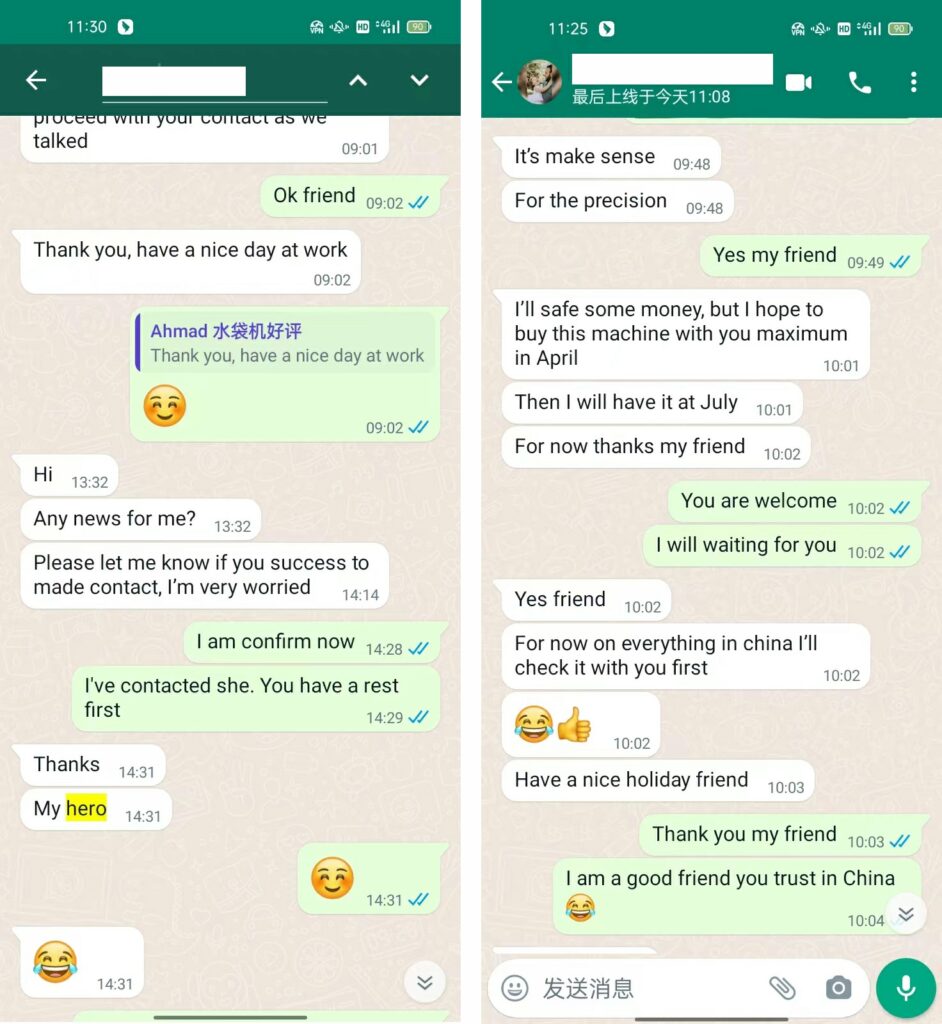

Our customers’ Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.

After customers get our machines,as the beginners,they always don’t know how to run the machine or how to adjust the machine.We will give them technical guide in time until they can use the machines properly.

All of our services and technical helps made our customers enjoy doing business with our company.In my opinion,we win these complements not only because the good quality of our machines,but also our professional and immediate services.

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.