I have collected two frequently asked questions about the packing machine from customers I have encountered recently, and today I will summarize them here.

The most important and customer-related issue is often the packing machine price, but the quotation is based on certain information. For our packing machine, the information I need to know in the early stage is what materials the customer needs to pack, the gram weight of the bag, the length and width of the bag, and the sealing method. Without this information as a background basis, it is impossible to determine the exact model of the packing machine, and it is impossible to accurately quote. So in order to help you make the most suitable solution in the shortest time, please give us all the requirements and known information.

The customer said that if the same material is packaged but different size bags are used for packaging, can one machine satisfy it? This question is also frequently asked by customers in the field of automatic packing machine. For example, many food and snack processing factories often pack the same food into different bags. This requires the customer to provide the specific size of each bag, because our packaging machines are divided into sizes and models according to the width of the packaging film. If the width of the bag can be within the range of one machine, it is only necessary to change the shaper of a different type. That is, if it cannot be within a range, it is necessary to replace multiple packaging machines.

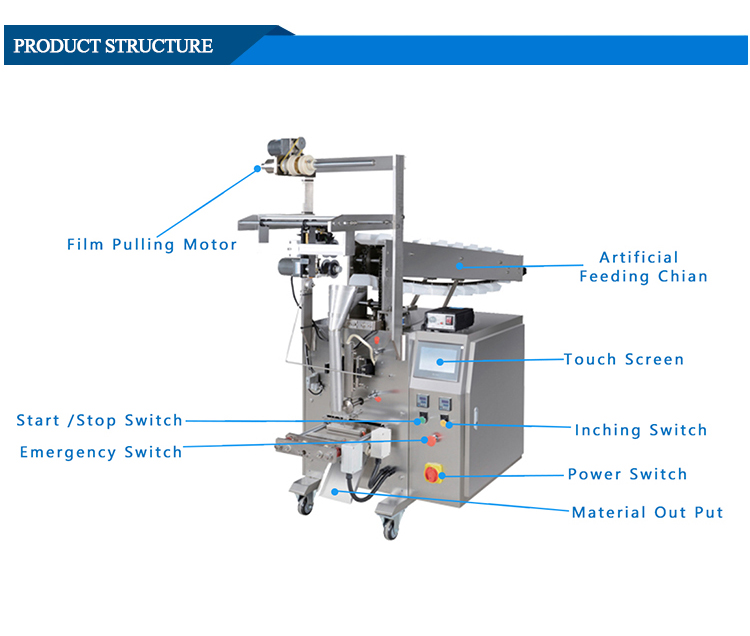

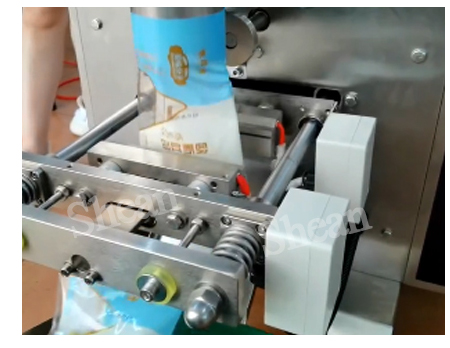

Pictures of the machine and detail parts

Advantages of the Packing Machine

1.The bucket conveyor uses semi automatic feeding,which is suitable for packing various products and east to change products to have muti usage.

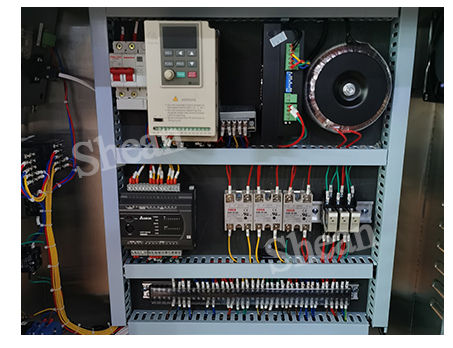

2.The electric box uses CPU intelligent single chip computer system for efficient running.

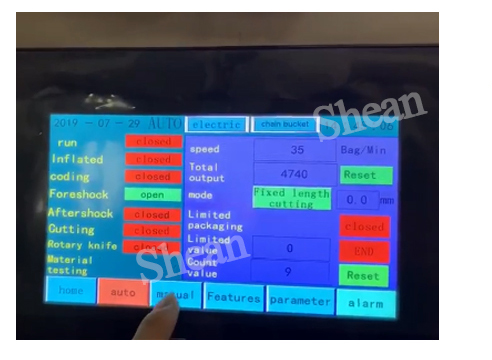

3.The 7 inch touch screen has easy operation and customized multiple language to choose.

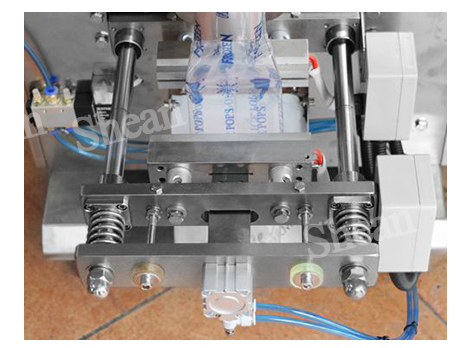

4.Accuracy Vertical sealing, horizontal sealing and cutting can make the beautiful and practical bags.

5.The separate PID temperature controller is suitable for various packing material,It is easy to change the temperature to suitable for aluminium film,paper film,PE film and composite film.

6.The articulated bag former structure enables stable bag forming for perfect bag shaping.

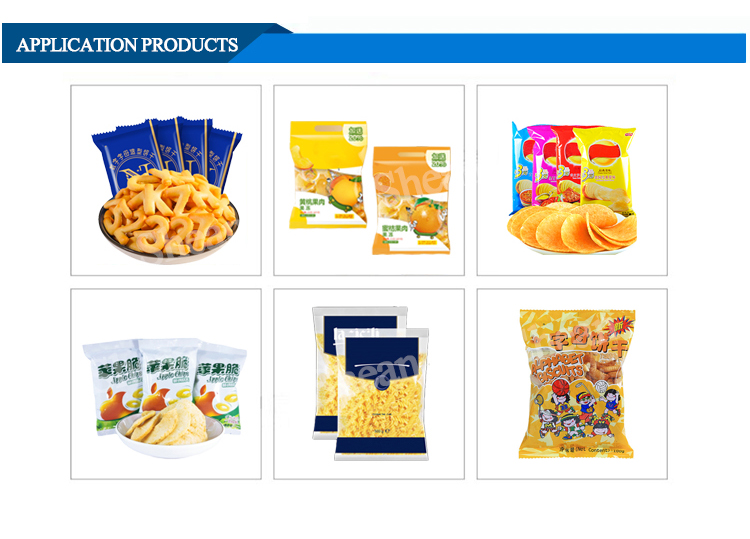

Application Picture

This packaging machine is suitable for automatic bag packaging of irregular materials or non-viscous coarse powder materials in food, chemical, hardware and other granular products, such as: wakame, shrimp skin soup, seaweed, flower tea, nuts, health tea, dried peppers , wolfberry, rose, jujube tablets, astragalus tablets, longan, tea, soybeans, Qingbuliang and so on.

Description about Automatic Powder Filling Machine

| Model | SH-160B |

| Measurement | Semi Automatic |

| Film Width(Bag former) | Max 320mm(back seal 60-320mm3 side seal 10-300mm4 side seal 140-280mm) |

| Bag Width | 30-200(If special order can do 250mm) |

| Measurement range | 20-250ml |

| Packing Speed | 10-70bag/min |

| Biggest Film Diameter | 300mm |

| Film Thickness | 0.04-0.08mm |

| Packing film materials | Laminate plastic |

| Power | 220V,50/60HZ,Single Phase |

| Weight | 300kg |

| Machine Size | L1100*W755*H1730mm |

| Remark | Mechanical Type |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

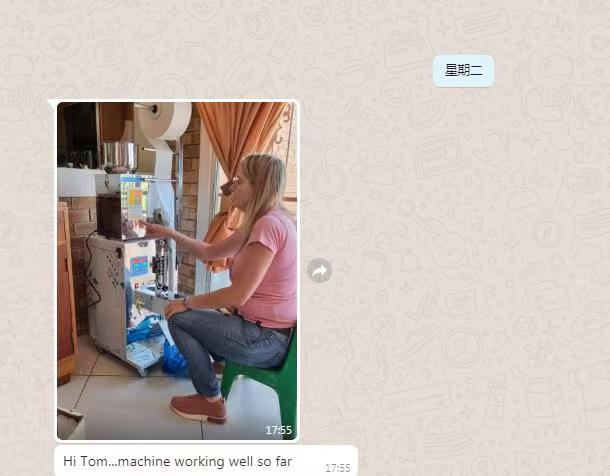

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.