No matter how good the quality of the powder packaging machine is, in order to prolong its service life, it needs reasonable maintenance and maintenance. However, there are many customers who do not know the importance and maintenance methods of powder packaging machine maintenance, so for the maintenance and maintenance of powder packaging machine, I will organize them as follows:

1. Add oil to lubricate:

It is necessary to regularly lubricate the meshing parts of the gears of the powder filling and sealing machine, the oil injection hole of the bearing with a seat and the moving parts of the machine, once per shift, and the reducer is strictly prohibited from running without oil. When adding lubricating oil, be careful not to sprinkle oil droplets on the rotating belt, in order to prevent slippage and loss or premature aging of the belt and damage.

2. Regularly clean the powder packaging machine:

After the shutdown, it is necessary to clean the metering part and the heat sealing mechanism in time, especially some packaged materials with high sugar content in the granules, clean the turntable and the unloading door, and the heat sealing mechanism is also a part that needs to be cleaned frequently to ensure the sealing of the finished packaged products. The lines are clear, and the scattered materials should be cleaned up in time to facilitate the cleaning of the parts, so as to better prolong their service life. At the same time, the dust in the electric control box should be cleaned frequently to prevent electrical failures such as short circuit or poor contact. .

3. Maintenance of powder packaging machine:

Maintaining the powder packaging machine is one of the keys to prolonging the life of the packaging machine. Therefore, the screws of each part of the powder packaging machine should be checked frequently, and there must be no looseness. Otherwise, the normal remote rotation of the whole machine will be affected. Moisture-proof, anti-corrosion, anti-rat, to ensure that the electric control box and the terminals are clean, to prevent electrical failures, after the shutdown, the two heat sealers should be in the open position to prevent scalding the packaging materials.

If you want to know more details about the powder packing machine price,please contact me with your detailed information about your products.Thanks for reading.

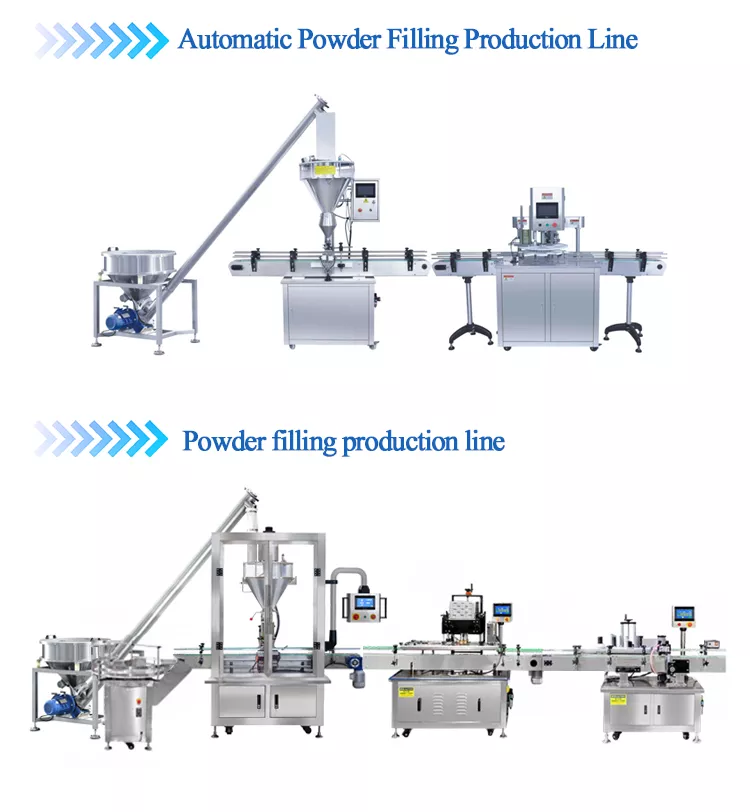

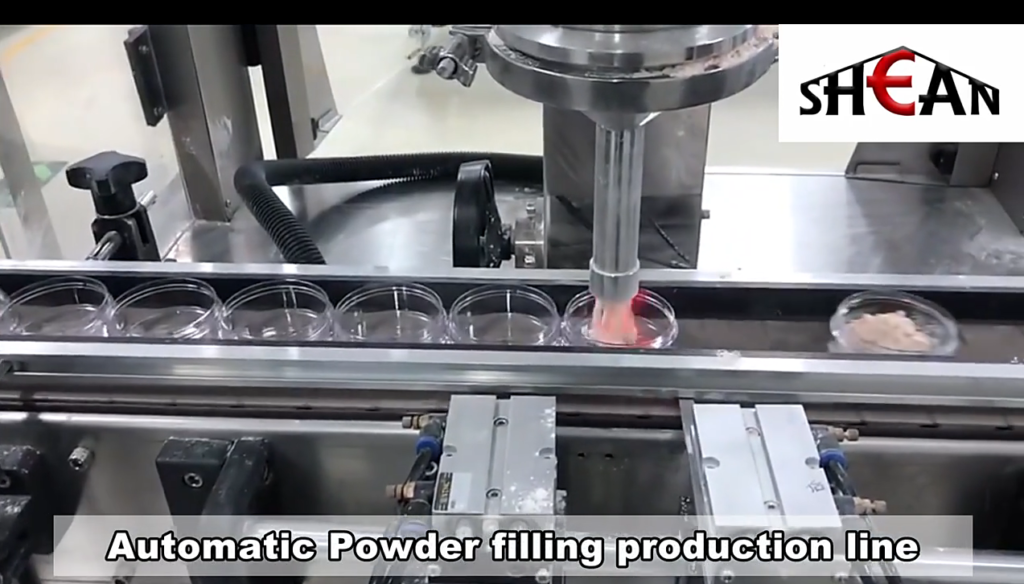

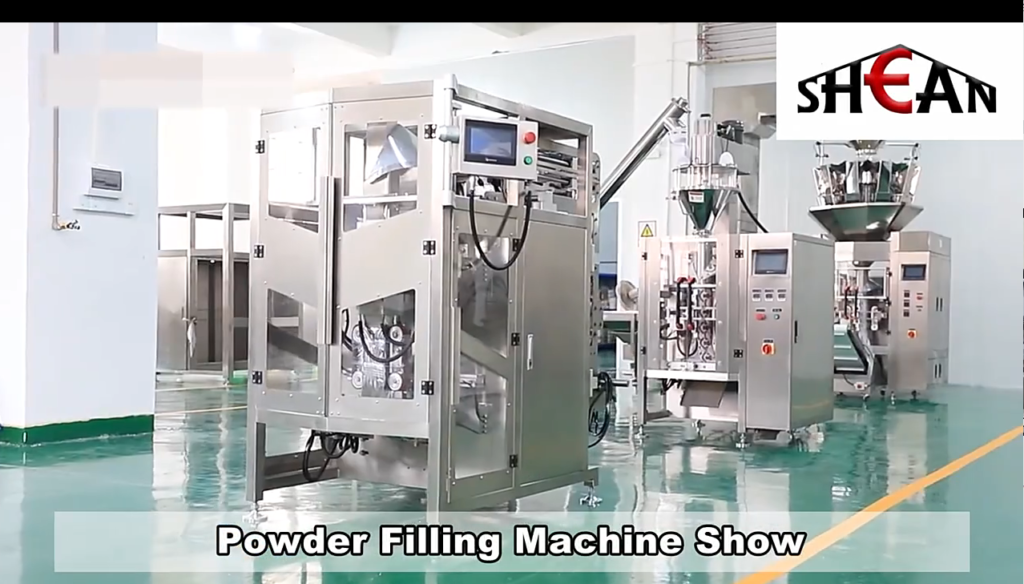

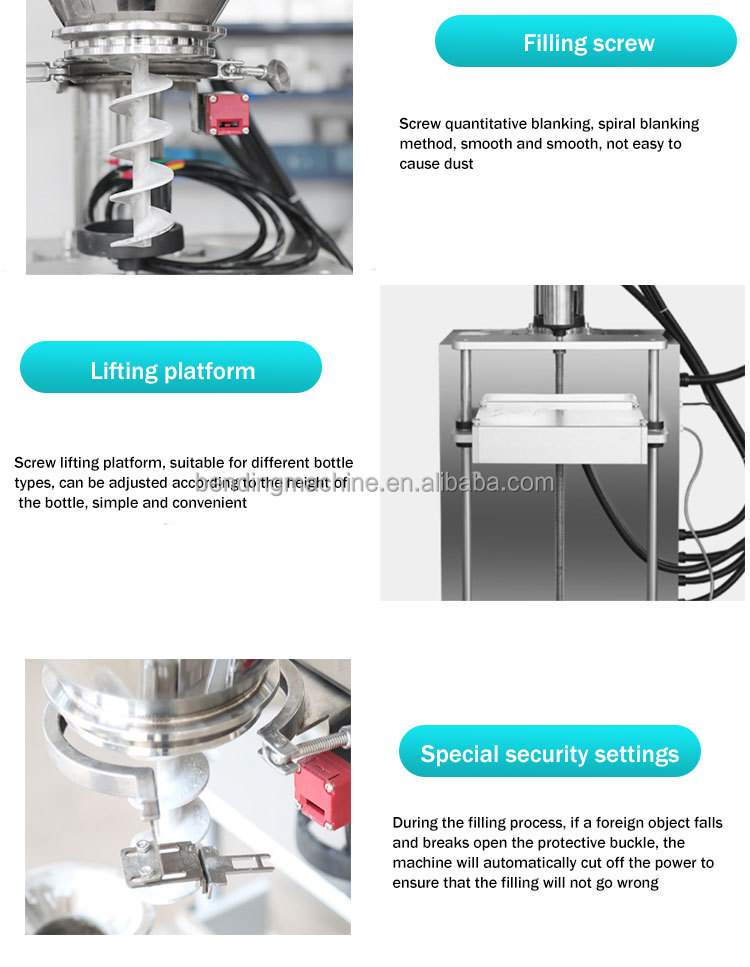

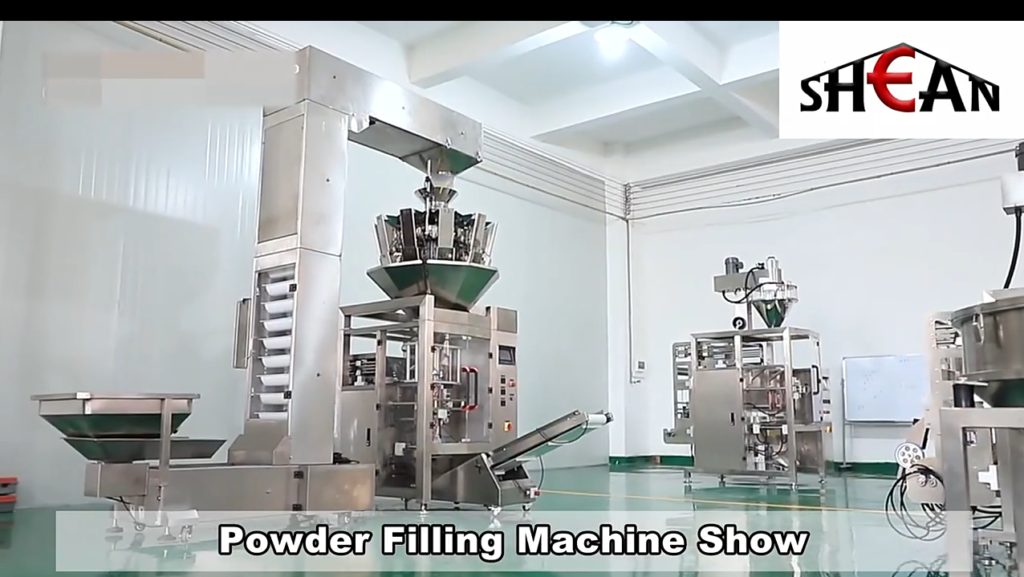

Pictures of the machine and detail parts

Advantages of the Powder Packaging Machine

1. The whole machine has compact structure, stable performance, small footprint and easy maintenance.

2. The parts in contact with the material are made of 304 stainless steel to ensure the safety and hygiene of the product.

3, Chinese and English LCD display, easy to understand, easy to operate, good stability.

4. Using high-precision stepping motor, the same position of each bag pattern is accurate.

5. The control system completes the synchronization, fixed length, positioning and speed of the whole machine, and automatically diagnoses faults.

Powder Packaging Machine features:

Application Picture

The powder packaging machine is a material-targeted packaging equipment, that is to say, in terms of material adaptation, the material targeted by this packaging equipment is powder, so it is called a powder packaging machine. Although they are picky about materials, the powder packaging machine still has a wide range of applications, because there are powder products in various industries, such as the pharmaceutical industry, the food industry, etc.

Description about Powder Packaging Machine

| Model | LT-730 |

| Packaging materials | Powder |

| Filling weight | 10-2000g |

| Weighing scale | 1-6000g |

| Filling accuracy | <0.5% |

| Filling speed | 30-45piece/min |

| Power supply | 380/220v 50-60hz |

| Total power | 1.8w |

| Total weight | 150kg |

| Machine volume | 3000×1060×2000mm |

| Container volume | 75L |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Powder Packaging Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

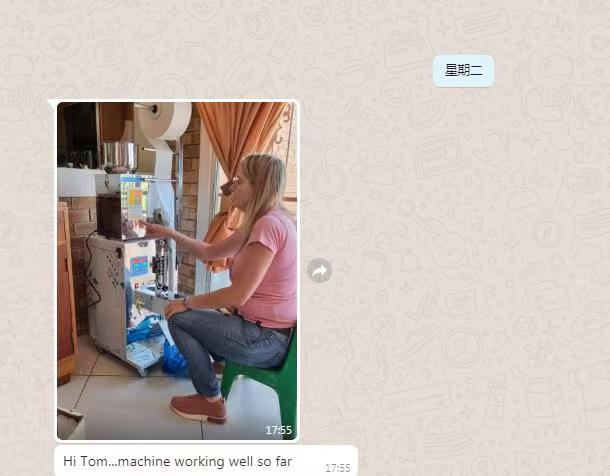

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.