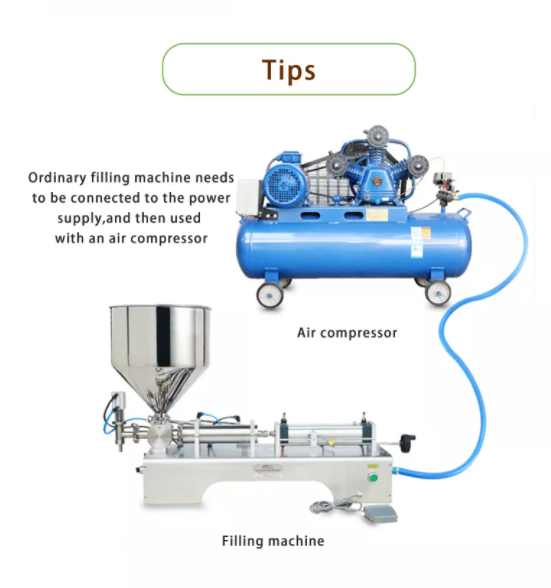

Semi-automatic liquid filling machine can be divided into semi-automatic filling machine and automatic filling machine according to the degree of automation. Semi-automatic bottle filling machine is the most common semi-automatic filling machine. So how does it work, let us see.

Work flow and advantages of semi-automatic filling machine

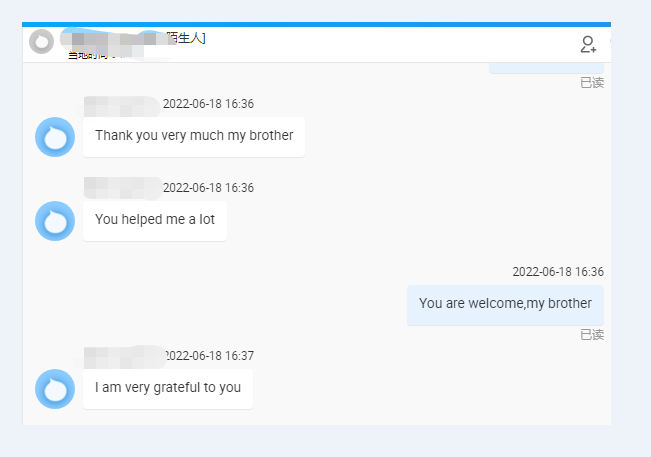

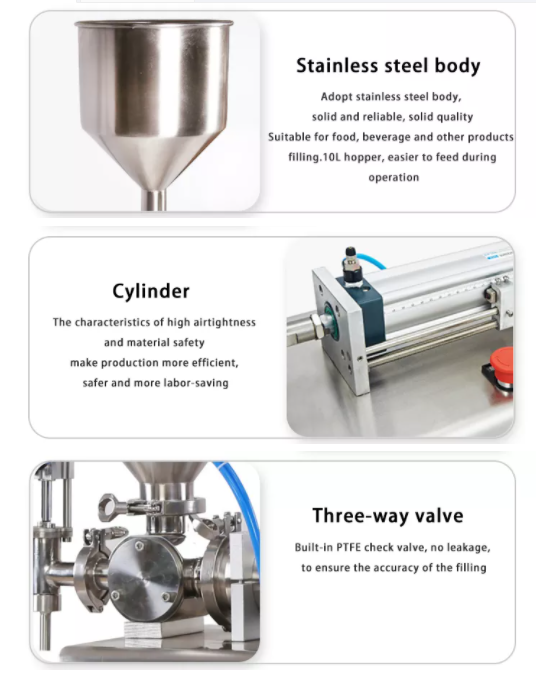

1, The use of compressed air as control, so it is suitable for use in the environment with explosion-proof requirements.

2, will not produce static electricity, hemp electric phenomenon, also do not need grounding.

3, due to the use of start control, and the use of hard positioning, so the filling precision is high, the accuracy can be controlled within 0.3% (based on the filling amount as the standard)

4, In the case of emergency stop, need to close the pneumatic switch, piston automatically back to the initial position, filling stop.

Automatic piston type liquid filling machine for each filling is a mechanical single simple action, so for each regular container has a high filling accuracy and stability.

Semi-automatic filling machine is a convenient and fast new machine, in the process of use, there are small problems, you can adjust it, such as oil filling machine filling dose is not accurate: first check whether the feeding system of the equipment failure.

Then the pipe cleaning can check whether there is debris in the material.

Then replace the pneumatic valve sealing ring, air leakage, replace the pneumatic valve.

If the material of the oil filling machine cannot be filled, check whether the nozzle is closed, restart the machine, check whether the air pressure is normal, and whether the injection cylinder and cylinder leak.

The material reaches the limit, not enough to fill the corresponding container.

After a simple adjustment and inspection, we can use the oil automatic filling machine to work, so as to achieve the advantages of fast and good saving of machinery instead of manpower.

1. The filling volume of semi-automatic piston type edible oil filling machine is unstable, and the time is more or less

A. Check whether there is wine leakage at the wine inlet of the filling machine. If there is, exclude it until there is no wine leakage.

B. Check whether there is any foreign matter in the wine inlet valve that causes the valve to be closed loosely. If there is, remove it in time.

2. Dripping of filling head

A. Whether the semi-automatic filling machine works wobbly, if so, check whether the four anchor screws are in stable contact with the ground.

B. Check whether there is any foreign matter in the filling valve, and remove it in time if there is.

Semi-automatic Filling Machine Application

It is suitable for quantitative filling of liquids, pastes and other substances in chemical, food, daily chemical, pharmaceutical, pesticide, lubricating oil and other industries.

Semi-automatic filling machine video

Parameters about Semi-automatic Filling Machine

| Device name | Semi-automatic Filling Machine |

| The power supply | 220V 50Hz |

| Canned precision | ≤±1% |

| Canned speed | 5-25 bits/min |

| With the pressure | 0.4-0.6MPa |

| With gas | ≥0.1m3/min(This machine is a pneumatic machine, need to own air pump) |

| Filling range | 10-100ml,30-300ml,50-500ml,100-1000ml,500-3000ml,1000-5000ml |

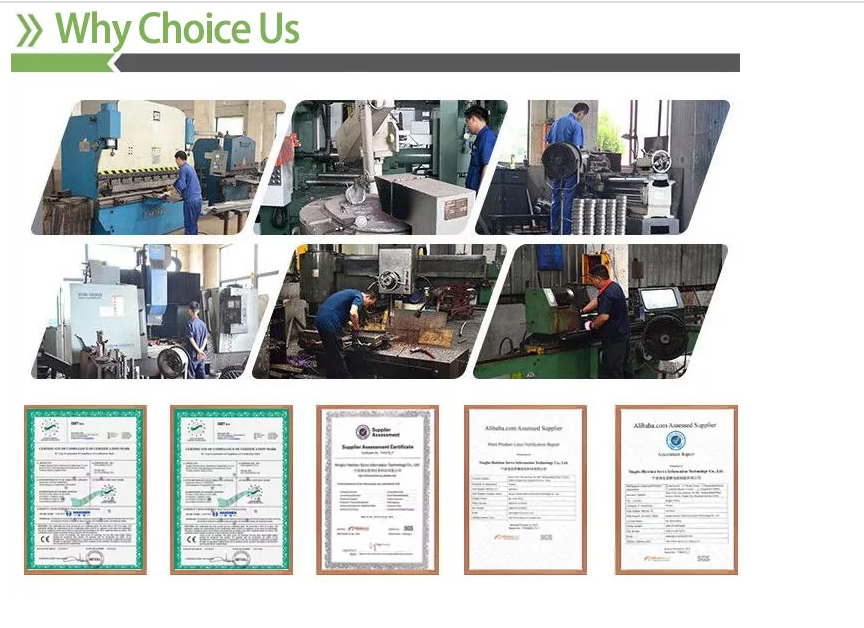

Our company

Shean is a professional manufacturer of various filling machines.Rooted in filling machine industry for more than 20 years. We have full production experience, advanced technology and constantly updated products. Enjoy a high reputation among users.

Our company meets the needs of customers with technical innovation and attention to the reliability of overall performance. Shean’s main products are varies of filling and packing machines.

For the highest goal we are pursuing, we provide customers with turnkey projects such as design, manufacture, installation and commissioning, after-sales service and technical training for engineering projects.

We share the latest technology with you and provide the service, your trust is our aim.

Piston filling machine Packing & Shipping

The inside of the package is wrapped with plastic film, and the outside uses an export wooden box. The wooden box meets the export standards, and the fumigated wooden box is anti-insect and moisture-proof, which can also reduce customs difficulties.

Our Customer Reviews

Shean company focuses on machine sales and service for 10+ years. We not only provide customers with complete machine solutions, but also focus on helping to solve installation and debugging problems! Customer satisfaction is our pursuit.