Automatic Dry Soda Detergent Powder Filling Machine

Product Description

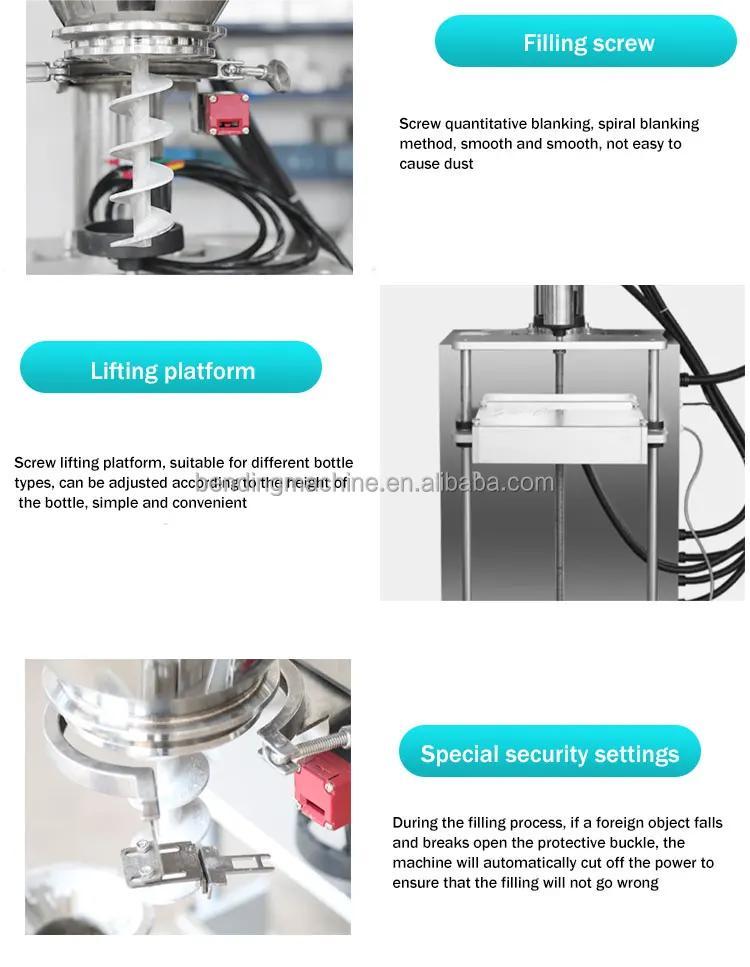

Powder filling machine is suitable for quantitative filling of powdery, powdery and powdery materials in chemical, food, agricultural and sideline products and other industries; such as: milk powder, starch, pesticides, veterinary drugs, premixes, additives, condiments, feed, Enzyme preparations, etc.; this automatic quantitative filling machine is suitable for quantitative packaging of powders in various packaging containers such as bags, cans, bottles, etc.; this powder filling machine integrates machinery, electricity, light, and instruments, is controlled by a single-chip computer, and has automatic Quantification, automatic filling, automatic adjustment of measurement errors and other functions; fast speed: using spiral blanking and light control technology; using stepper motor to achieve high measurement accuracy.

Product Features

1.powder/flour bag filling machine Material is stainless steel 304(touch food parts), meet GMP standard

2.Servo control auger,much more stable and accuracy -Step motor can be economical customized

3.PLC+ Touch screen control, English version interface

4.Electric scale or load cell connect with touch screen for weight feedback, machine can be used by weight or by volume according the user need

5.Same material same screw ,once 1 spec parameter item preset , just change the target weight on work page then inner item like the fast filling weight , slow filling weight and mini weight value will be change automatically

6.Changing the auger attachment, it fits for lots of material ranging from fine-powder to granule.

7.Top Hopper equipped with level sensor to control the feeding machine work automatically

8.Foot Pedal control filling

9.50L Hopper can be half open and it more easy for screw change or inner wall cleaning

10.Stand pole of filler is in round shape. All parts like the electric cabinet ,touch screen box ,bag clamper or scale frame etc fixed on it easily by metal clamper .

11.Material entrance and dust exit on both side of auger filler .it can be changeable so feeder can be placed from different side according user workshop situation.

12.Insider mixing blade can be adjustable by bolts to match different size screw to assure the accuracy when packing

Product Application

Product Parameter

| Model | SH-26 |

| Packaging materials | Powder |

| Filling weight | 10-2000g |

| Weighing scale | 1-6000g |

| Filling accuracy | <0.5% |

| Filling speed | 30-45piece/min |

| Power supply | 380/220v 50-60hz |

| Total power | 1.8w |

| Total weight | 150kg |

| Machine volume | 3000×1060×2000mm |

| Container volume | 75L |

Product Details

发表回复