Automatic Powder Filling of which the instructions that are surely helpful

With the continuous advancement of packaging machinery technology in automatic powder filling machine, many unnecessary manual operation failures have been reduced and a lot of time has been saved. However, when running the automatic powder filling machine, there are sometimes some operating problems, but in fact, these problems can be avoided in advance. Let me briefly talk about it today:

1. Before starting the machine, check whether the operating mechanism of each part of the automatic powder filling machine is faulty, whether the screws are loose or falling off, and whether the electronic control box is well connected to the outside.

2. Turn on the power, turn on the power switch, and turn off the brake switch (turn off the brake button on the function keyboard).

3. Cut the packaging material into sharp corners, then put it into the pulley through the mold, turn the conveyor belt, and pull it to the vicinity of the conveyor belt. At this time, the heat seal body should be aligned with the middle of the packaging color mark, and then place the cutting knife at the 1-2 color mark points (depending on the length) of the cross sealing path of the heat seal body. Note that the cutter should first align the bedknife with the color code, then fix the upper knife lugs on the top and back of the bedknife, slowly press down the front knife edge to cut off the wrapping paper, and do not break the knife edge when the cutter cuts.

4. Control and adjustment of the light spot detector. After the above adjustment, insert the material into the guide paper of the photoelectric detection head. After the green (red) point of the photoelectric detection head is aligned with the edge of any color mark above the forming device, lock the photoelectric detection head and manually place the wrapping paper between the color mark in the lamp and the base. The green (red) spots of the hair move up and down. The sensitivity indicator on the back of the photodetector should change between red and green indicators. Normally, when the colored punctuation marks are on, the red light is on; when there is no punctuation, the green light is on. In the absence of the above changes, the sensitivity knob can be adjusted to meet the above requirements.

5. The powder filling and sealing machine adopts the form of stainless steel gong rod for metering and cutting, which is adjusted by stepper motor and metering controller.

These steps seem very complicated,specially to the auger powder filling machine.But It doesn’t matter if you don’t understand them, because our company will have technical staff who will answer your technical questions online 24 hours a day and give you technical guidance. We will also provide customers with detailed English instructions. Guarantee the production operation of customers to the greatest extent.

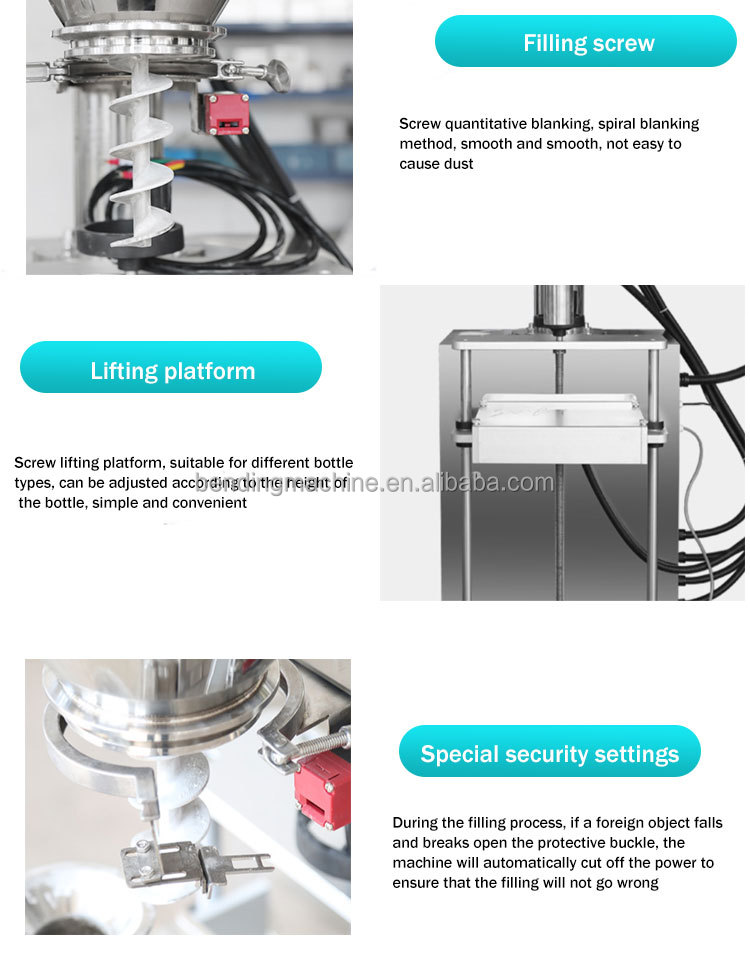

Pictures of the machine and detail parts

Advantages of the Automatic Powder Filling Machine

1. The whole machine has compact structure, stable performance, small footprint and easy maintenance.

2. The parts in contact with the material are made of 304 stainless steel to ensure the safety and hygiene of the product.

3, Chinese and English LCD display, easy to understand, easy to operate, good stability.

4. Using high-precision stepping motor, the same position of each bag pattern is accurate.

5. The control system completes the synchronization, fixed length, positioning and speed of the whole machine, and automatically diagnoses faults.

Automatic Powder Filling Machine features:

Application Picture

Automatic Powder Filling Machine is suitable for small bag packaging of medicine, food, chemical industry, pesticide and so on. It is suitable for the production of powder medicines, sugar, coffee, fruit, tea, monosodium glutamate, salt, seeds, desiccant and other powder products manufacturers.

Description about Automatic Powder Filling Machine

| Model | LT-730 |

| Packaging materials | Powder |

| Filling weight | 10-2000g |

| Weighing scale | 1-6000g |

| Filling accuracy | <0.5% |

| Filling speed | 30-45piece/min |

| Power supply | 380/220v 50-60hz |

| Total power | 1.8w |

| Total weight | 150kg |

| Machine volume | 3000×1060×2000mm |

| Container volume | 75L |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Automatic Filling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

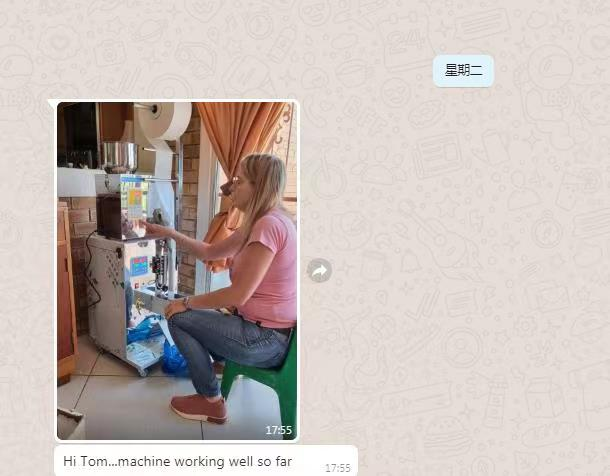

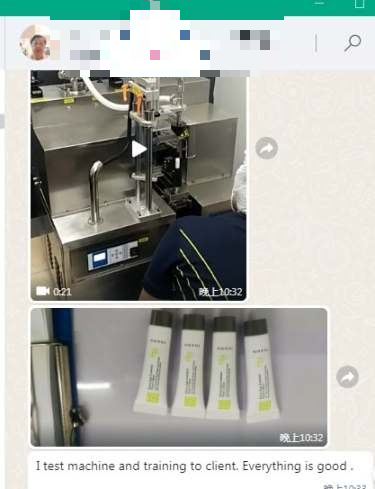

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.

发表回复