Semi Automatic Labeling Machine

The semi automatic round bottle labeling machine belongs to the series of semi automatic labeling machines. It is a labeling machine used for labeling round bottles such as PET bottles, plastic bottles, glass bottles, and metal bottles. The operating system, we will introduce the specific operation method of the semi automatic labeling machine in detail below.

Installation: Refer to the packing list and install the semi automatic labeling machine according to the instructions. It is packaged with the whole machine without packing list and can be used directly.

Label loading: Loosen the seven-character handle on the tray to remove one side tray, put the label roll on it, and then lock the tray. Be careful not to clamp too tightly, it is better to drag the label by hand.

Winding labels: according to the winding diagram, correctly wind the labels on the semi automatic bottle labeling machine.

Debugging: In the jogging state, observe the changes of the electric eye. When there is a gap between the labels, the red light of the electric eye is on, indicating the output signal. If the state of the electric eye is abnormal, please refer to the chapter on electric eye adjustment to adjust the electric eye.

Trial run: In the state of automatic operation, step on the foot switch once to observe the state of the label at the position of the stripping plate.

Trial paste: put the product on the labeling station, observe the position of the label on the workpiece, and adjust the position of the label on the workpiece by moving the positioning lever on the left.

Shutdown: After the labeling is completed, turn off the power in time, and unplug the power socket if it is not used for a long time.

Pictures of the machine and detail parts

Advantages of the Semi Automatic Labeling Machine

1.The machine is made of overall aluminum alloy. It has the characteristics of corrosion resistance and wear resistance,and can be used in relatively harsh environments.

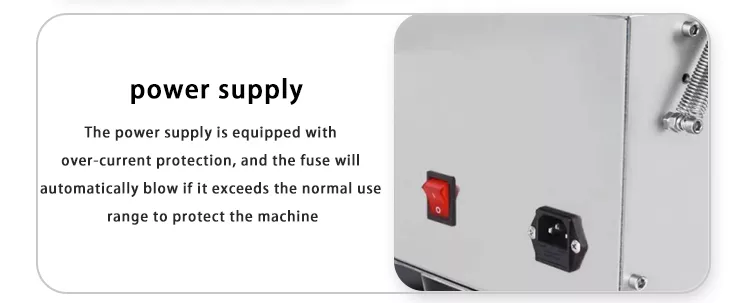

2.The power supply is equipped with over-current protection,and the fuse will automatically blow if it exceeds the normal use range to protect the machine.

3.The output power is larger ,the operation is more stable,and there will be no problems when running for a long time.

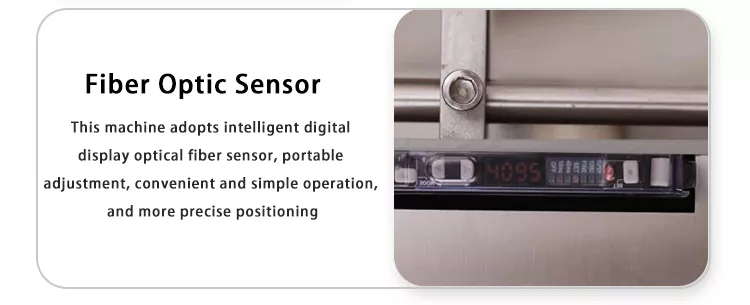

4.This machine adopts intelligent digital display optical fiber sensor,portable adjustment convenient and simple operation, and more precise positioning.

Semi Automatic Labeling Machine features:

Application Picture

The round bottle labeling machine is mainly used in the automatic labeling of various products suitable for vertically placed cylindrical bottles such as medicine, daily chemical industry, and food. It adopts an adjustable bottle dividing device and cooperates with a high-precision and high-speed labeling device to adapt to labeling products of various sizes.

Description about Semi Automatic Labeling Machine

| Product number | MT50 Sticker Paste Label Machine |

| Out Power | AC 220V/50HZ |

| Power | 100W |

| Max Label Size | Width:150mm Length:300mm |

| Min Label Size | Width:20mm Length:25mm |

| Label roll out diameter | ≤OD 275mm |

| Label roll inside diameter | OD 75mm |

| Available bottle diameter | 15-120mm |

| Paste tolerance | ±0.5 mm |

| Working efficiency | 20-50 pcs/min(depends on work piece diameter) |

| Machine weight | 25kg |

| Machine dimension | 650*345*450mm |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing beverage, paste, beer, oil, milk, Bird’s nest

filling-packing equipments ,water treatment equipments. Aseptic carton packaging machine, manual liquid filling machine. The quality already pass drinkable standard.

At present we produce: production lines for mineral water, pure water, fruit juice,tea drink,milk drink and carbonated drink with capacity 1000-20000bottles/hour; production lines for vinegar, soy sauce and wine 1000-20000bottles/hour; 3-5 gallon barreled water with capacity 60-1200 barrels per hour and water treatment plants 1-30 ton/hour; Aseptic carton packing machine 2400ctn/h, 3500ctn/h. We provide separate machinery or turnkey project.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Semi Automatic Labeling Machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

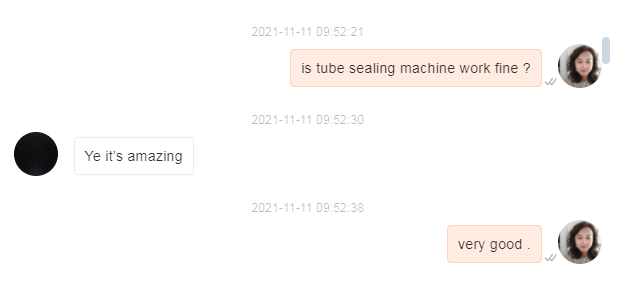

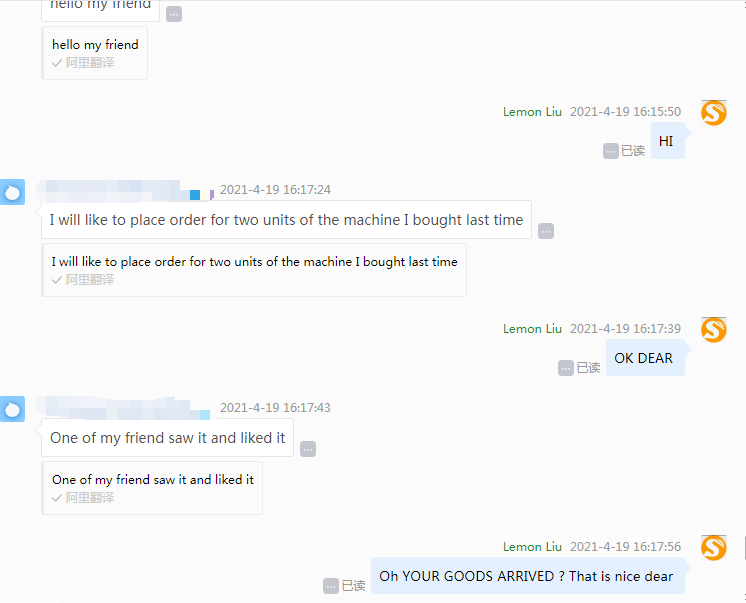

Our customers’ Reviews

we make machines more than 10 years and services 1000+ big and small factories and get many repeat orders. in 2019-2021, 2 years,we export 1500sets to only 2 customers. This is big honor to get user’s trust. All the customers feel machine quality is good,efficiency is good and maintenance is easy, so they like to give repeat machine orders. Even some one recommend his friend to us.

发表回复