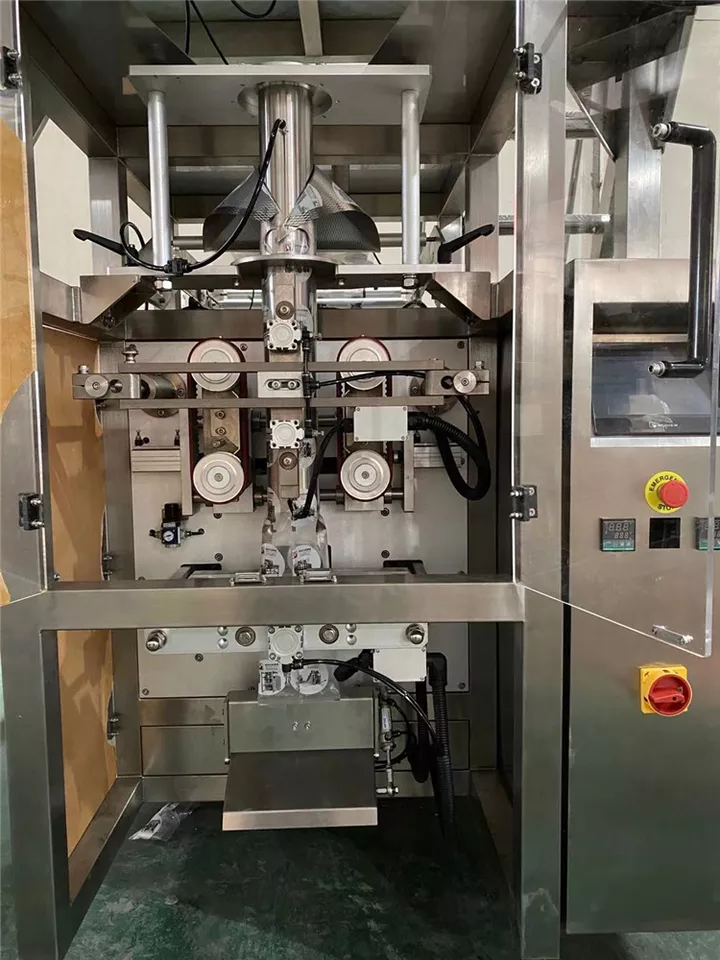

The bag packing machine adopts ultrasonic sealing to realize triangular cone and flat bag packaging, which is suitable for mixed packaging of various materials. The machine is suitable for filling and sealing small grain-like materials, such as tea, herbs, green tea, black tea, mix tea and so on. It with PLC control system, color touch screen, this machine is a latest type packaging machine for pyramid tea bag. The bag packing machine of main feature of the machine is one-time packing for the thread, tag and outer bag, avoiding hands directly contacting with stuff materials, improving the efficiency.

The bucket packing machine can pack inner bag into outer bag automatically.

It is photoelectric location for the tag and outer bag, adjustment to the need of the content, length of bag, and tag. The dimension of bag can be adjusted according to the need that to achieve the perfect shape, to upgrade the appearance for the product, then add the value of it.

The bag packing machine consist of ELECTRICAL SCALE WEIGH that 14/10 heads multi-heads weigh. German HBM loadcell, accuracy is in +/-0.1g/bag. Storage of 100 sets of parameters. Exceeding weight tea directly kick out. SMART CONTROLL SYSTEM that A key to control the machine, all functions automatically start 10 seconds not work, the ultrasonic part automatically shuts off. Shown the failure parts on touch screen. Set up shift production Easy to connect with other machine. SEALING PARTS That High capacity 90-100bags/min Meet to Europe standard production.

Small tea packing machine with Auto stop working and relieve pressure, when open the safe door. Safety relay to provide double security. FILM is Suitable for 120/140/160/180mm film width.

Tagged or no Tagged. Step motor for automatic tension adjustment. All kinds of ultrasonic film could work well .

Tea bag packing machine with temperature of sealing for filter tea bags and outer envelope bags and tags are controlled separately by PID, which is

suitable for tightly sealing for different package material and different thickness material.

the sealing type can be customized to heat sealing for filter paper or ultrosonic sealing for non-wovens fabric.

Weighing by measuring cup, the accuracy can reach 99%, save labor, and can weigh 1-20G. This machine is an automatic multi-functional tea bag packaging equipment with a new heat sealing type. The inner and outer bag forming is finished at the same time, avoid direct contact with the packing material and improve working efficiency. Inner bag is made of filter paper, and outer bag is made of Composite paper.

Advantages of bag packing machine

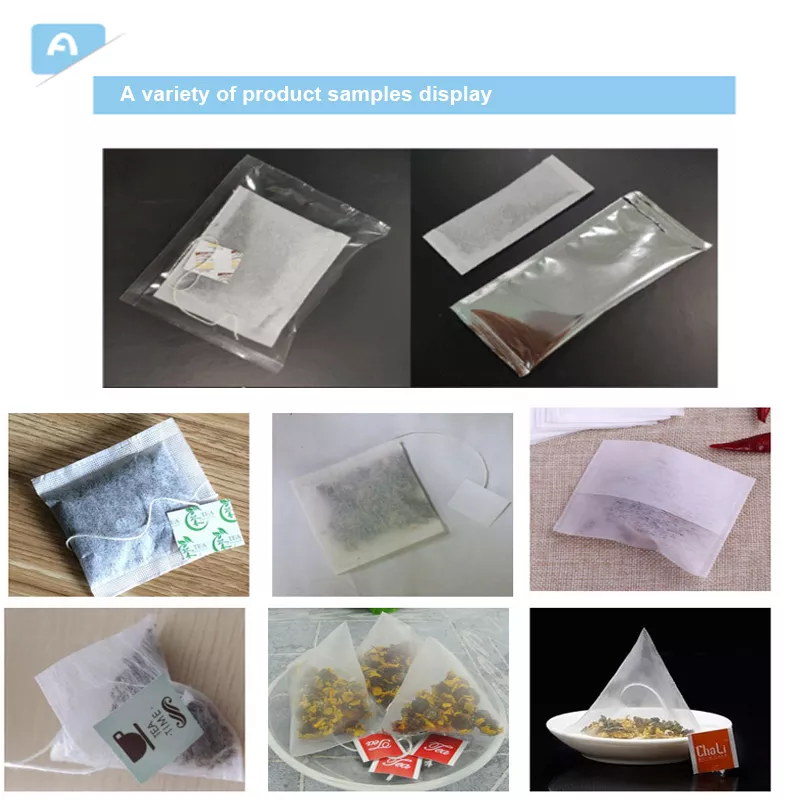

1. It can be used for flat bag packaging, triangular three-dimensional packaging and other forms of packaging bags.

2. The whole machine can automatically complete the functions of feeding, measuring, bag making, sealing, cutting, counting, and finished product conveying.

3. The precise control system is used to adjust the movement of the whole machine, the structure is compact, the man-machine interface is designed, the operation is convenient, the adjustment is easy, and the maintenance is easy.

4. Imported ultrasonic sealing is used, and the electronic weighing method is used to measure the material. The sealing is firm and the material is accurate.

5. Automatic adjustment device for packaging material tension.

6. Automatic alarm and automatic shutdown function in case of failure.

7. The packaging material is suitable for nylon film

Application of bag packing machine

bag packing machine is Suitable for packaging all kinds of flower tea herbal tea fruit tea and Vegetable seeds are packaged, granulated or powdered pharmaceutical products are packaged

Bag packing machine video

Description about the bag packing machine

| Model | TP-P100 |

| Measurement methods | 14 heads electronic scales |

| Packing material | Nylon, PET, Non-Woven Fabric, PLA… etc. (ultrasonic sealing filter/mesh) |

| Bag size | Triangular: 50–80 mm (each edge) Rectangular: 40–80 (W) x 50–80 (L) mm |

| Sealing methods | Ultrasonic sealing |

| Packing film width | 120-180mm |

| Production | 90-100 bags/min |

| Overall dimension | L1844 x W2900x H2862 mm |

| Weight | 1500kg |

Our company

Shean ( Cangzhou) Corp Ltd which has more than 20years, the company is growing up time by time in research and design, quality and production, sales and after sale service. Our machineries are sold to more than 50 countries and over cross domestic.

We specialize in producing all kind of goods or liquid or paste packing machine. The beverage, paste, beer, oil, milk, Bird’s nest illing-packing equipments ,water treatment equipments is blong us our production area.

Our products pass quality inspection executed by Bureau of Quality and Technical Supervision every year. We pass Italy CE inspection in 2011.

We have full-time development and design engineer team, we absorb technologies from Germany, Japan, France, Italy, Switzerland, combined with international technologies to develop high starting point and advanced technology filling equipments, degree of automation to achieve the advanced level.

We own 3700 square meters modern factory in accordance with ISO9001: 2000 certification system standards with all kinds of advanced processing equipment and testing equipment, experienced technicians, scientific and strict management, all constitute SHEAN excellence in product manufacturing system, which provides the professional protection for SHEAN product quality.

Chip packing machine Packing & Shipping

Our products are packed in wooden boxes. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxes are damaged or other situations happen, you can contact us anytime.

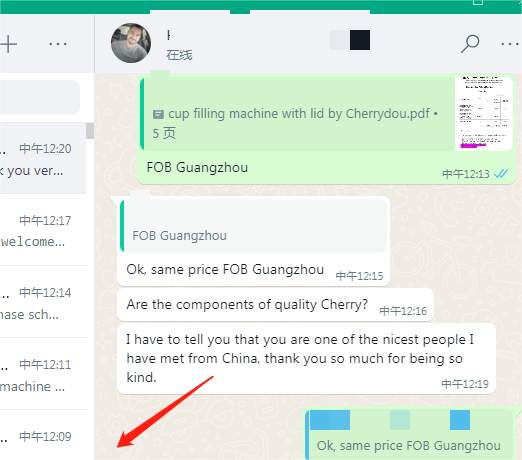

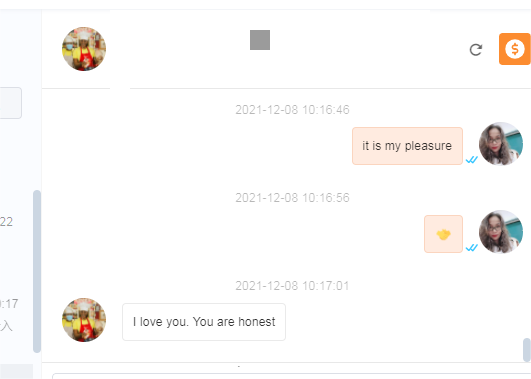

Our Customer Reviews

From the moment customers place an order, our after-sales and technical services begin. First, update production information and transportation information to customers at any time, so that customers can clearly know what stage the purchased machine is in, and be 100% assured.