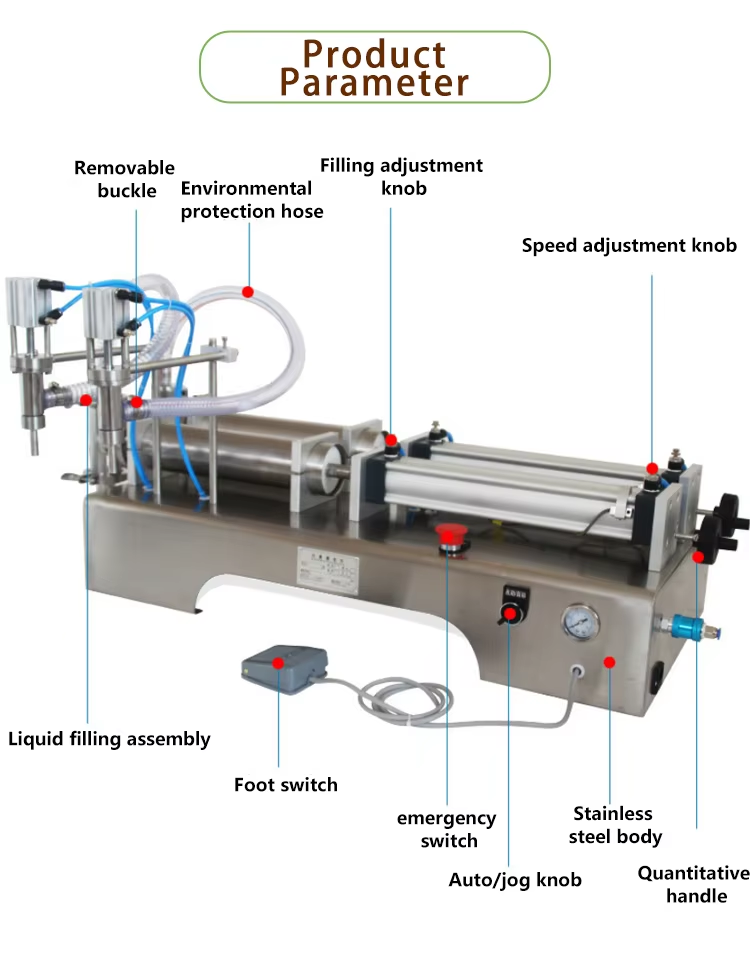

Small Double-Head Juice Beverage Liquid Filling Machine

Product Overview

The Small Double-Head Juice Beverage Liquid Filling Machine is a compact, efficient, and easy-to-operate solution designed for filling various liquid products such as fruit juices, beverages, flavored drinks, vitamin drinks, herbal liquids, and other water-based liquids. With its twin-filling nozzles and high-precision control system, this machine is ideal for small and medium manufacturers seeking reliable liquid filling performance with improved productivity.

Built with food-grade materials and advanced liquid control technology, it ensures hygienic operation, stable filling, and excellent cost-effectiveness for juice and beverage production lines.

Key Features

✔ Double-Head High-Efficiency Filling

The dual filling nozzles allow two bottles to be filled simultaneously, significantly increasing production efficiency.

Each filling head works independently, ensuring:

Stable flow rate

Accurate filling volumes

Consistent performance

✔ Suitable for a Wide Range of Liquids

Designed for low-viscosity and medium-viscosity liquids, including:

Fruit juice

Soft drinks and flavored beverages

Tea drinks

Sports and energy drinks

Vinegar, soy sauce, and condiments

Water and herbal extracts

✔ Food-Grade Construction

All liquid-contacting components are made from food-grade stainless steel to meet hygiene and safety standards.

The machine offers excellent corrosion resistance and easy cleaning for daily operation.

✔ Accurate Volume Control

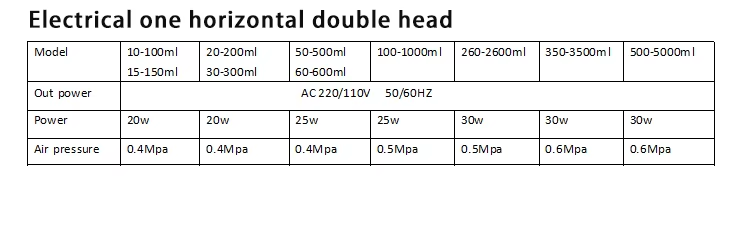

Using high-precision cylinder or servo control (depending on configuration), the machine maintains accurate filling volumes for every cycle.

Operators can easily adjust filling time, speed, and dosage to meet different product requirements.

✔ Easy to Operate and Maintain

The clear control panel makes setting parameters simple and intuitive.

Quick-change filling nozzles and modular parts ensure easy cleaning and maintenance, even in small workshops.

✔ Anti-Drip Design

Special anti-drip filling valves ensure clean filling without leaking or splashing, keeping bottles and the working area tidy.

Working Process

Place empty bottles on the working platform or feeding conveyor.

Start the filling cycle—the two heads fill bottles simultaneously.

Filling volume is automatically controlled to meet preset requirements.

Filled bottles are removed manually or transferred to the capping machine.

Optional integration:

Bottle clamp system

Automatic bottle feeding and discharging

Liquid mixing tank

CIP cleaning system

Technical Advantages

Compact size suitable for limited spaces

High output for small-scale production

Stable performance with minimal maintenance

Adjustable filling speed and volume

Compatible with various bottle shapes (plastic, glass, PET)

Affordable, suitable for startups and small beverage factories

Applications

This twin-head liquid filling machine is widely used in:

Juice and beverage factories

Small drink production workshops

Food and condiment packaging lines

Health drink and herbal liquid producers

Water and tea drink bottling

Start-up beverage brands

Why Choose Our Double-Head Liquid Filling Machine?

We design our machines for durability, hygiene, and efficiency. The small double-head liquid filling machine provides:

Reliable production performance

Accurate filling quality

Easy operation for any skill level

Affordable pricing with excellent value

Whether you are starting a new beverage line or upgrading existing equipment, this machine offers the perfect combination of precision, speed, and simplicity.

发表回复